Have you ever wondered how intricate metal parts are made? One tool stands out: the CNC metal lathe motor. This amazing machine shapes metal with precision. But what exactly is a CNC metal lathe motor? It combines advanced technology with traditional craftsmanship.

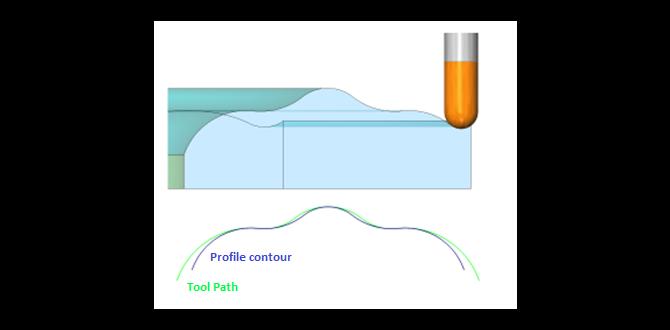

Imagine a spinning piece of metal. As it turns, the CNC lathe uses tools to carve and cut it into a specific design. It’s like turning a block of clay into a beautiful vase, but with metal!

Here’s a fun fact: these machines can create parts used in cars, planes, and even toys! The CNC metal lathe motor helps designers and makers bring their ideas to life.

In this article, we’ll dive deeper into how CNC metal lathe motors work. You’ll learn why they are so important and how they are used in various industries. Get ready to discover the magic behind this incredible tool!

Understanding Cnc Metal Lathe Motor: Essential Guide To Precision Engineering

A CNC metal lathe motor is essential for shaping metal with precision. It powers the lathe, allowing it to rotate and cut material accurately. Think of it like a magic wand that molds metal into useful parts. Choosing the right motor affects speed and torque, which impacts your projects. Did you know that different motors suit various tasks? This knowledge can elevate your crafting skills significantly. Understanding CNC metal lathe motors opens up new possibilities in metalworking!

What is a CNC Metal Lathe Motor?

Definition and basic function of a CNC metal lathe motor. Different types of CNC metal lathe motors available in the market.

A CNC metal lathe motor is a device that helps shape metal pieces. It spins materials while cutting tools shape them into desired forms. This motor is essential for making parts in machines and tools. Different types of CNC metal lathe motors include:

- Stepper Motors: Great for precise movements and control.

- Servo Motors: Known for their speed and accuracy.

- DC Motors: Simple and easy to use for basic tasks.

Each of these types serves a unique purpose in metalworking, making tasks easier and more efficient.

What do CNC metal lathe motors do?

They power the lathe, allowing it to cut and shape metal. This process helps create strong and precise parts.

Benefits of Using a CNC Metal Lathe Motor

Improved precision and accuracy in metalworking. Increased efficiency and productivity in manufacturing processes.

Using a cnc metal lathe motor transforms metalworking. It ensures improved precision and accuracy. This means your projects turn out just right every time. A cnc lathe reduces mistakes. You get better results faster. In manufacturing, this leads to increased efficiency and productivity. Workers can make more items in less time. It’s a smart choice for any metal shop!

What are the main benefits of using a cnc metal lathe motor?

The main benefits include precision, accuracy, and efficiency. These improvements help workers create quality products quicker and with fewer errors.

Key Benefits:

- Higher precision in cuts and designs

- Less material waste

- Faster production times

- Improved consistency across products

Key Features to Consider When Choosing a CNC Metal Lathe Motor

Motor power and torque specifications. Compatibility with CNC systems and software requirements.

Picking the right CNC metal lathe motor is like choosing the perfect ice cream flavor. First, think about the motor power and torque. More power means better performance. Next, compatibility with your CNC system is key. If it doesn’t match, it’s like trying to fit a square peg in a round hole! Lastly, check the software requirements. You wouldn’t want to put pineapple on your pizza, right? Make sure everything works smoothly together.

| Feature | Importance |

|---|---|

| Motor Power | Higher is better for efficiency |

| Torque | Essential for strong cutting capability |

| Compatibility | Ensures smooth operation with your CNC system |

| Software Requirements | Must match for effective use |

Common Applications of CNC Metal Lathe Motors

Industries where CNC metal lathe motors are utilized. Examples of projects and products made using CNC metal lathes.

CNC metal lathe motors are powerful tools used in many industries. They help create precise parts with ease. Here are some common fields where they are useful:

- Aerospace – Parts for flying machines.

- Automotive – Components for cars and motorcycles.

- Manufacturing – Equipment for machines and tools.

- Medical – Devices and instruments for healthcare.

Some examples of products made with these lathes include:

- Robot parts – Used in factories.

- Custom tools – Specially designed for specific tasks.

- Jewelry components – Unique designs created for beauty.

Using CNC metal lathe motors ensures precision and speed, making work easier and products better.

Why are CNC metal lathe motors important?

CNC metal lathe motors provide accuracy and efficiency. They help create complex shapes quickly, which saves time and money.

Maintenance Tips for CNC Metal Lathe Motors

Routine maintenance checks and procedures. Troubleshooting common issues with CNC metal lathe motors.

To keep your CNC metal lathe motor happy and healthy, routine checks are a must. Check for loose screws and clean the motor regularly. This helps avoid sudden surprises, like the motor taking an unexpected vacation. If the motor makes weird noises, it might be time for a quick troubleshooting session. Listen for clicks or hums! Don’t forget, a little oil goes a long way. Remember, even motors love a spa day!

| Common Issue | Possible Cause | Solution |

|---|---|---|

| Noisy Operation | Loose parts | Tighten screws |

| Overheating | Insufficient lubrication | Apply oil |

| Poor Performance | Worn-out belts | Replace belts |

The Future of CNC Metal Lathe Motors

Emerging technologies in CNC lathe motors. Predictions for advancements in speed, efficiency, and capabilities.

The world of CNC metal lathe motors is about to get a turbo boost! Emerging technologies are set to make these motors faster and more efficient than ever. Imagine cutting time in half! Experts predict that improvements in speed, efficiency, and capabilities will turn ordinary tasks into high-speed adventures. With smart sensors and AI integration, a CNC lathe might soon be able to play chess while it works. Now, that’s multitasking!

| Year | Speed (RPM) | Efficiency (%) | Capabilities |

|---|---|---|---|

| 2023 | 1,500 | 85 | Basic Operations |

| 2025 | 2,000 | 90 | Automated Adjustments |

| 2030 | 3,500 | 95 | Smart Processing |

Conclusion

In conclusion, a CNC metal lathe motor is essential for precision machining. It powers the lathe, allowing you to create intricate designs. Understanding its function helps you improve your projects. We recommend reading more about the different types of motors and their features. This knowledge will enhance your skills and inspire your creativity in metalworking. Keep exploring!

FAQs

What Are The Typical Power Ratings And Specifications Of Motors Used In Cnc Metal Lathes?

CNC metal lathes usually have motors that range from 1 to 10 horsepower. This means they can be strong enough to cut metal. The motors often run on electricity and can spin very fast. You might see speeds between 1,000 to 5,000 revolutions per minute. This helps make precise and smooth shapes from the metal.

How Do Different Motor Types (Stepper, Servo, And Brushless Dc) Impact The Performance And Accuracy Of A Cnc Metal Lathe?

Different motor types help CNC metal lathes work better in different ways. Stepper motors move in small steps. This helps with accuracy for simple tasks. Servo motors are faster and can be very precise, making them great for detailed work. Brushless DC motors are super efficient and work smoothly, which can improve speed and finish. Each motor type plays a role in how well the lathe performs.

What Maintenance Practices Are Essential For Ensuring The Longevity And Optimal Performance Of A Cnc Metal Lathe Motor?

To keep a CNC metal lathe motor running well, we should check and clean it often. You need to make sure it has enough oil. Look for dust or dirt, and wipe them off. Also, check the wires for any damage. Lastly, don’t forget to follow the manufacturer’s instructions for care.

How Can The Choice Of Motor Affect The Speed And Torque Capabilities Of A Cnc Metal Lathe During Operation?

The motor in a CNC (Computer Numerical Control) metal lathe helps control how fast and strong it works. A stronger motor can give you more torque, which helps cut metal better. If the motor spins fast, it can make the lathe work quicker. Choosing the right motor means you can get the best speed and strength for your job.

What Are Common Troubleshooting Steps For Issues Related To The Motor Of A Cnc Metal Lathe?

If the motor of a CNC (Computer Numerical Control) metal lathe is not working, we can try a few things. First, check if it’s plugged in and the power switch is on. Next, look for any loose wires or connections. We can also make sure the motor isn’t too hot. If all looks good and it still doesn’t work, you might need to call a repair person.