Have you ever watched a lathe machine in action? It’s fascinating to see how metal turns into intricate shapes. A CNC metal lathe is a machine that does just that, but it can be even more amazing with a power feed. What is a power feed, you ask?

A power feed allows the lathe to move automatically while cutting. This feature makes the job easier and faster. Imagine working on a project and not having to manually turn the handle every time!

Did you know that using a CNC metal lathe with a power feed can increase your precision? It helps create smoother and more accurate cuts. Many hobbyists and professionals love this combination because it saves time and effort.

So, if you’re interested in metalworking, understanding CNC metal lathes and their power feeds is important. It might just change the way you think about machining!

Cnc Metal Lathe Power Feed: Boosting Precision And Efficiency

Discover how a CNC metal lathe power feed can transform your machining tasks. This tool automates the movement of the cutting tool, making work faster and more precise. Imagine finishing projects in half the time! With adjustable speeds and better control, you can create smoother and more accurate parts. Plus, reduced operator fatigue is a game-changer. Learning about CNC power feeds can lead you to new possibilities in metalworking!

Types of CNC Metal Lathe Power Feeds

Explanation of different types: manual, automatic, and servodriven.. Pros and cons of each type to help users choose the right one..

There are three main types of CNC metal lathe power feeds: manual, automatic, and servo-driven. Each type has its own benefits and drawbacks.

- Manual: This type requires operator input for movement. It is cost-effective but demands more skill and attention.

- Automatic: This feed moves on its own. It’s easier to use but can be more expensive and may need repairs.

- Servo-Driven: This type is precise and efficient. While it can be costly, its accuracy can save time and materials.

Choosing the right type depends on your needs and budget. Think about what you value most: cost, ease of use, or precision!

What is the best type of CNC metal lathe power feed?

The best type largely depends on your goals. For learners or simpler tasks, manual may be best. However, for professional work, automatic or servo-driven might provide the best accuracy.

Benefits of Using a Power Feed in CNC Lathes

Increased efficiency and consistency in machining processes.. Improved accuracy and surface finish of the final product..

A power feed on a CNC lathe offers several benefits. It boosts efficiency during machining. The machine operates smoothly, reducing downtime. This makes work faster and easier. You’ll see better accuracy in measurements, leading to a perfect fit for parts. The final product has a nice surface finish, as power feeds help maintain consistent speed. This helps prevent defects and enhances quality.

Why use a power feed?

Using a power feed can speed up your work and make your products look better.

Key Benefits:

- Increased efficiency

- Improved accuracy

- Better surface finish

Key Components of CNC Metal Lathe Power Feeds

Breakdown of essential parts: motors, gears, and controls.. Functionality of each part in the context of performance..

Understanding the parts of a CNC metal lathe power feed can feel like assembling a giant robot from your childhood. First up, we have the motors. These little heroes make everything move smoothly and quickly. Next, the gears step in, like a great team of dancers, ensuring power is transferred accurately. Lastly, the controls are the brain of the operation, deciding how fast and how far everything goes. Together, they help the machine work like a well-oiled machine—or at least like a fun, slightly awkward robot dance!

| Component | Function |

|---|---|

| Motors | Drive movement smoothly. |

| Gears | Transfer power precisely. |

| Controls | Regulate speed and distance. |

How to Select the Right Power Feed for Your CNC Lathe

Factors to consider: lathe size, material types, and production volume.. Tips for matching power feed capabilities with project requirements..

Selecting the right power feed for your CNC lathe is like choosing the best tool for your project. You must consider several factors:

- Lathe size: Ensure the power feed fits well with your CNC lathe.

- Material types: Different materials need different feeds for the best results.

- Production volume: Higher volume often requires faster feeds.

Match the power feed capabilities to what you need. A strong power feed can enhance efficiency. Think about how often you will use the lathe. This helps you avoid buying more than you need.

What factors should I consider for CNC lathe power feed?

Focus on lathe size, material types, and production volume. These elements help ensure you choose the proper power feed for your projects.

Installation and Setup of CNC Metal Lathe Power Feeds

Stepbystep guide on installing a power feed system.. Common mistakes to avoid during setup..

Installing a power feed system on your CNC metal lathe can sound daunting, but it’s easier than pie—well, maybe easier than baking a pizza! Start with a clear workspace and gather your tools. First, attach the motor to the lathe. Next, connect the gearing and then the lead screw. Make sure to double-check every connection; a loose screw could mean trouble!

| Step | Action |

|---|---|

| 1 | Clear and prepare workspace |

| 2 | Attach motor securely |

| 3 | Connect gearing |

| 4 | Attach lead screw |

Common mistakes include not aligning parts correctly. Misalignment leads to malfunction. Remember, measure twice, cut once! Once installed, test the system gently to avoid surprises. Think of it like a first date: you want everything to go smoothly!

Maintenance Tips for CNC Metal Lathe Power Feeds

Routine maintenance practices to prolong lifespan.. Troubleshooting common issues and solutions..

Keeping your CNC metal lathe power feed in top shape is easier than you think! First, make it a habit to clean the machine regularly. A little cleaning goes a long way. Check for dirt and chips that could cause issues. Next, inspect belts and gears often. If they look worn, it’s time for a change. Regular oiling is also key; it’s like giving your lathe a well-deserved spa day!

If something doesn’t seem right, don’t panic! Most problems can be fixed with simple steps. For example, if you notice unusual sounds, check for loose parts. Why did the lathe fail its driving test? Because it couldn’t keep it together! Here’s a quick table for common issues and solutions:

| Problem | Solution |

|---|---|

| Strange noises | Tighten loose components |

| Poor feeding | Lubricate moving parts |

| Inconsistent speed | Check motor connections |

Following these simple tips keeps your lathe chipper and happier!

Real-World Applications of CNC Metal Lathe Power Feeds

Examples of industries utilizing power feeds for operational success.. Case studies showcasing productivity improvements..

CNC metal lathe power feeds help many industries create parts more easily. For example, the automotive industry uses these machines to make car parts efficiently. They can quickly shape and cut metal, saving time and money. Other industries, like aerospace, benefit too. A case study showed one factory improved its productivity by 30% after using power feeds. This upgrade allowed them to produce more parts faster and meet demands better.

What industries use CNC metal lathe power feeds?

Many industries use CNC metal lathe power feeds. These include automotive, aerospace, and manufacturing. Each benefits from faster production and improved efficiency.

Examples of benefits:

- Faster production times.

- Less waste during machining.

- Better quality of finished parts.

Future Trends in CNC Metal Lathe Power Feeds

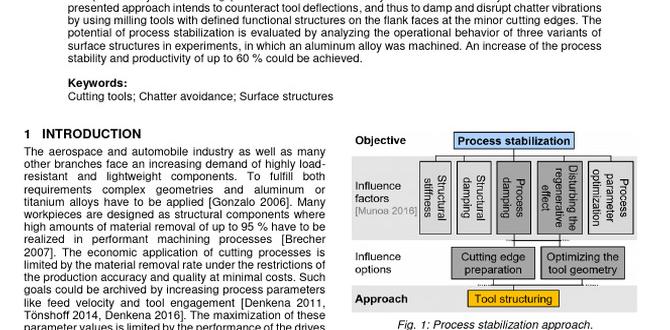

Innovations in technology and their impact on power feed systems.. Predictions for the evolution of CNC machining processes..

Technology keeps getting better. New cnc metal lathe power feed systems are coming out. They help machines work faster and more accurately. Innovations like smart controls and automation make a big difference. More companies use these tools for production. Predictions say that as technology grows, CNC machining will become even more precise. This will lead to improved designs and faster work. Exciting changes are on the way!

How will CNC machining evolve?

Experts believe CNC machining will be more automated and precise. New tools will help machines work together better. This means fewer mistakes and smoother operations.

Resources for Further Learning

Recommended books, websites, and courses on CNC machining and power feeds.. Online forums and communities for knowledge sharing and support..

If you want to learn more about CNC machining, many resources are available. You can check out these suggestions:

- Books: Look for titles on CNC machining basics and advanced techniques.

- Websites: Visit sites like CNC Cookbook and The Engineering Toolbox for tutorials.

- Online Courses: Platforms like Udemy and Coursera offer courses on CNC machining.

- Forums: Join communities like CNC Zone and Reddit’s r/CNC for advice and support.

These resources can greatly help your journey into the world of CNC metal lathes and power feeds!

Where can I find good CNC machining books?

Check your local library or online stores for popular books on CNC machining, including guides for beginners and experts alike.

Conclusion

In summary, a CNC metal lathe with a power feed makes machining easier and faster. It helps you create precise parts with less effort. Using this equipment can improve your skills and efficiency. We encourage you to explore tutorials online or practice with a project. Happy machining!

FAQs

What Are The Advantages Of Using A Power Feed System On A Cnc Metal Lathe Compared To Manual Feeding?

Using a power feed system on a CNC metal lathe is easier and faster than manual feeding. It helps you cut metal smoothly and without tiring your hands. With power feed, you can make precise cuts every time. You also spend less time adjusting things, allowing you to finish projects quickly. Overall, it makes the job more fun and efficient!

How Does The Power Feed Mechanism Affect The Accuracy And Precision Of Machined Parts On A Cnc Lathe?

The power feed mechanism helps move the cutting tool smoothly on a CNC lathe. When the tool moves evenly, it makes better cuts. This means the parts we create are more accurate, so they fit together nicely. If the tool moves too fast or too slow, the parts might not turn out as we want. So, a good power feed makes sure everything is just right!

What Types Of Materials Are Commonly Processed Using Power Feed Systems In Cnc Metal Lathes?

CNC metal lathes use power feed systems to work with different materials. You can process metals like steel, aluminum, and brass. These materials are strong and used in many things. Sometimes, we also work with plastics. They help create shiny parts and tools for machines.

How Can Operators Adjust The Feed Rate In A Cnc Metal Lathe To Optimize Machining Efficiency And Finish Quality?

To adjust the feed rate on a CNC metal lathe, you can change how fast the machine moves the metal. A faster feed rate might be good for quickly making parts, but it can make the finish less smooth. If you slow down the feed rate, the cut will be finer and the finish will look nicer. You should test different speeds to find the best balance between speed and quality. This way, we can save time and make better parts.

What Troubleshooting Steps Should Be Taken If A Power Feed System On A Cnc Lathe Is Not Functioning Properly?

First, check if the CNC lathe is plugged in and turned on. Next, look for any loose or broken wires. You can also check the control panel for error messages. If those steps don’t work, ask someone with more knowledge to help. Remember to always be safe when working with machines!