Exciting Cnc Metal Lathe Projects For Creative Makers

CNC metal lathe projects can transform your ideas into reality. Imagine creating custom parts or unique designs with ease! You can learn to build anything from simple tools to complex machinery. These projects often enhance problem-solving skills and creativity. Did you know that even small projects can lead to big improvements in your crafting skills? With a CNC lathe, precision becomes your best friend, allowing you to achieve results you might not believe possible.

Understanding CNC Metal Lathes

Explanation of CNC (Computer Numerical Control) technology. Advantages of using CNC lathes in metalworking.

Imagine a machine that makes parts by following computer instructions. That’s a CNC lathe! CNC stands for Computer Numerical Control. It helps machines cut and shape metal pieces with great accuracy. Using CNC lathes has many benefits:

- Precision: They create exact shapes.

- Speed: They work faster than manual machines.

- Consistency: Each part is the same every time.

- Reduction of Waste: Less material goes unused.

This technology makes metalworking easier and more efficient.

What does CNC stand for?

CNC stands for Computer Numerical Control. It means computers control machines for precise tasks.

What are the benefits of using CNC lathes?

The benefits include accuracy, speed, consistency, and less waste. They help makers produce better metal parts.

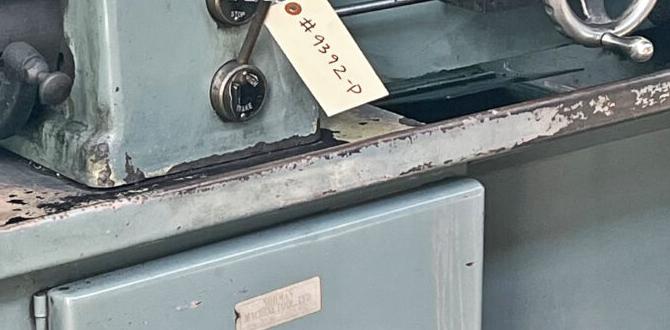

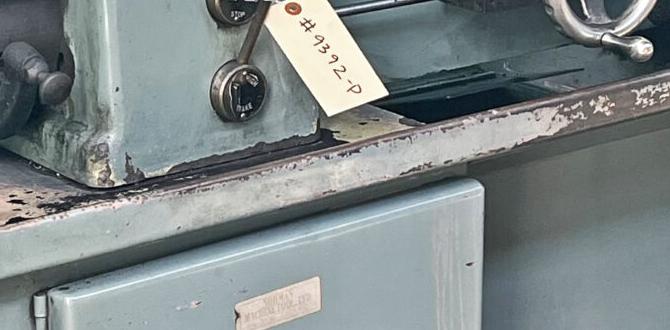

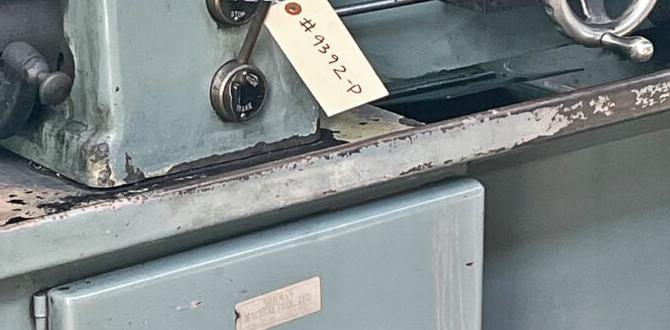

Essential Tools and Equipment for CNC Metal Lathe Projects

List of necessary tools for CNC projects. Safety equipment and protocols.

Starting a CNC metal lathe project needs some cool tools. First, you’ll want a sturdy CNC lathe machine. Next on the list are cutting tools like HSS and carbide inserts. Don’t forget measuring tools like calipers and micrometers for precision—because we want things to fit, not wiggle! Safety gear is super important too. Always wear goggles, gloves, and ear protection. Remember, safety first; injuries don’t make for funny stories!

| Tools and Equipment | Safety Gear |

|---|---|

| CNC Lathe Machine | Safety Goggles |

| Cutting Tools (HSS, Carbide) | Ear Protection |

| Measuring Tools (Calipers, Micrometers) | Work Gloves |

With these essentials, you’re all set to start creating magic on that lathe. Happy machining!

Top CNC Metal Lathe Project Ideas for Beginners

Simple projects to get started, such as bottle openers and knobs. Importance of understanding basic operations and programming.

If you’re new to cnc metal lathe projects, starting with simple items can help. Fun ideas include:

- Bottle openers

- Knobs for drawers

Making these simple tools teaches you the basics of how a CNC lathe works. It’s great to learn basic operations and programming. Mastering these skills will boost your confidence and make you a better maker!

What should beginners know about CNC metal lathe projects?

Beginners should start with easy projects. This helps them learn important skills like programming and machine operation. Understanding these basics is key to creating successful projects.

Advanced CNC Metal Lathe Projects for Experienced Users

Complex project examples, including custom gears and mechanical components. Tips for enhancing project precision and complexity.

Taking on advanced CNC metal lathe projects can be exciting! These projects allow you to make custom gears and mechanical components. Here are some examples you might enjoy:

- Creating different types of gears like spur and helical gears.

- Building custom brackets for various machines.

- Crafting complex pulleys for your projects.

To make your projects even better, focus on precision. Here are some tips:

- Always measure twice before cutting.

- Use sharp tools for a clean finish.

- Pay attention to your machine settings.

With practice and patience, you’ll be amazed at what you can create!

What are some project ideas for advanced CNC metal lathe users?

You can create custom gears, mechanical parts, and unique brackets. These projects will help improve your skills and boost your creativity!

Designing Your CNC Metal Lathe Projects

Software options for project design (CAD/CAM tools). Workflow processes from design to execution.

Choosing the right software is important for your cnc metal lathe projects. CAD/CAM tools help you create designs easily. These tools let you draw and plan your projects before you start working. A good workflow keeps everything organized. Here’s how it usually goes:

- Design the part in CAD software.

- Convert the design to G-code with CAM software.

- Load the G-code into your CNC lathe.

- Start machining and check the results.

With good software and a clear plan, you can make your projects run smoothly and look great!

What software can I use for designing?

Popular CAD software includes AutoCAD and SolidWorks. For CAM, try Fusion 360 or Mastercam. Each tool has its own strengths, so pick one that fits your project best.

Common Challenges in CNC Metal Lathe Projects

Troubleshooting common issues. Maintaining equipment for optimal performance.

CNC metal lathe projects can be tricky, like trying to find a sock that matches your other sock! Common problems may include tool chatter or inaccurate cuts. Regular maintenance is key. Clean your tools and check for wear like you’re checking your snack stash! With proper care, your lathe runs smoother, like butter on warm toast. Remember to troubleshoot quickly to keep projects on track and avoid surprises.

| Challenge | Solution |

|---|---|

| Tool Chatter | Decrease spindle speed or change the cutting tool. |

| Inaccurate Cuts | Check tool alignment and recalibrate settings. |

| Overheating | Ensure proper lubrication and cooling. |

So, take care of your equipment, and laugh through the mishaps. Mistakes can lead to fun stories and better skills!

Best Practices for Successful CNC Metal Lathe Projects

Tips for efficient programming and machining. Importance of regular maintenance and calibration.

To succeed in cnc metal lathe projects, follow these best practices. First, program your machine carefully. Use clear and organized codes to avoid mistakes. Next, always maintain and calibrate your tools regularly. This keeps them in good shape and ensures accurate cuts. A well-maintained machine lasts longer and works better.

- Check for any wear and tear.

- Lubricate moving parts often.

- Test your machine settings frequently.

By sticking to these tips, you will enjoy efficient and successful projects!

What are the key tips for CNC programming?

Use simple commands, double-check your work, and always test before the final run.

Why is maintenance important?

Regular upkeep prevents issues and helps your machine run smoothly, saving you time and money.

Showcasing CNC Metal Lathe Project Results

Ideas for displaying finished projects. Engaging with the CNC community for feedback and improvement.

Finished projects can shine when displayed well. Try placing them on shelves or in cabinets. Use lights to highlight their beauty. You can also create a mini-exhibit at local fairs or events. Connecting with the CNC community is crucial. Share photos online to get feedback and suggestions. This interaction helps improve your skills and craft. Here are some ideas:

- Join local maker groups.

- Participate in online forums.

- Attend exhibitions to meet other creators.

Why is feedback important for CNC projects?

Feedback helps you grow as a creator. It boosts your confidence and opens up new ideas. Different viewpoints can improve your projects greatly!

Conclusion

In summary, CNC metal lathe projects are fun and rewarding. You can create precise parts and improve your skills. Start with simple designs and grow your expertise. Explore tutorials and join online communities for more ideas. You’ll learn a lot and gain confidence. Now, grab a project and begin your CNC journey today!

FAQs

What Are Some Beginner-Friendly Cnc Metal Lathe Projects That Can Help Develop Machining Skills?

You can start with simple projects like making a pencil holder or a coaster. These items help you practice turning and shaping metal. You could also try creating small knobs or handles for practice. Each project helps you learn new skills and get better with the CNC metal lathe. Have fun and enjoy making things!

How Do You Choose The Right Materials For Cnc Metal Lathe Projects To Ensure Durability And Precision?

To choose the right materials for your CNC metal lathe projects, start by thinking about what you want to make. You should pick strong metals that can handle wear and tear, like steel or aluminum. Check if the metal is easy to cut and shape, so you get clean, precise edges. Finally, consider the cost and make sure it fits your budget. Always ask for advice if you’re not sure!

What Software Tools Are Commonly Used For Designing And Programming Cnc Metal Lathe Projects?

For CNC metal lathe projects, you can use software like CAD and CAM. CAD stands for Computer-Aided Design, and it helps you draw your designs. CAM means Computer-Aided Manufacturing, and it helps plan how to create your projects. We can also use G-code, which is a special language that tells the machine what to do. These tools make designing and making things easier and more fun!

What Safety Precautions Should Be Taken When Operating A Cnc Metal Lathe During Various Projects?

When using a CNC metal lathe, wear safety goggles to protect your eyes. Always keep your hair tied back and wear tight clothes. Make sure to check your tools and workspace for any problems before starting. Keep your hands away from moving parts. Finally, pay attention and follow instructions carefully to stay safe.

How Can You Troubleshoot Common Issues That Arise While Working On Cnc Metal Lathe Projects?

To troubleshoot problems with a CNC metal lathe, first check the machine’s settings. Make sure everything is correctly set for your project. If the machine makes strange noises, stop it and inspect for loose parts. Look for chips or dust that might be blocking tools. Finally, always read the manual for specific guides to fix issues.