Have you ever watched a machine spin and create something amazing? That’s the magic of a CNC metal lathe. Setting up this machine might sound hard, but it can actually be simple and fun! Imagine transforming a plain piece of metal into a beautiful part for a car or a tool for a workshop. With the right steps, anyone can learn how to set up a CNC metal lathe.

Picture this: you’re in a garage filled with metal shavings, a warm breeze blowing through, and the hum of machinery around you. It’s a creative space, full of possibilities. A CNC metal lathe allows you to cut, shape, and design objects with precision. But how do you get started with this incredible tool? In this article, we will guide you through essential parts of the setup process. You will discover tips, tricks, and the confidence to start your next project!

Cnc Metal Lathe Setup: A Comprehensive Guide For Beginners

Setting up a CNC metal lathe can seem tricky, but it’s much easier than it sounds. First, ensure your machine is level and secure. Next, align the tool correctly for precise cuts. Did you know that a well-setup lathe can reduce your work time significantly? Check the software settings to match the material. With the right setup, you can create amazing metal parts and enjoy the process of making something cool!

Understanding CNC Metal Lathes

Definition and function of CNC metal lathes. Comparison between manual and CNC lathes.

CNC metal lathes are machines that shape metal into specific forms. They work by spinning the metal and cutting it with sharp tools. These machines are precise and can create complicated parts quickly. Unlike manual lathes, which require hands-on control, CNC lathes operate using computer programs. This means they can produce the same part multiple times without mistakes.

- Manual Lathes: Operated by a person, allowing for more hands-on skill.

- CNC Lathes: Automated and programmed for exact cuts and shapes.

Manual lathes need more time and practice to master. However, CNC lathes make it easier for anyone to make perfect pieces.

What are CNC metal lathes used for?

CNC metal lathes are used to create a variety of metal parts, including gears, bolts, and custom machinery. They help in various industries like automotive, aviation, and manufacturing, making them essential tools for modern production.

Essential Components of CNC Metal Lathes

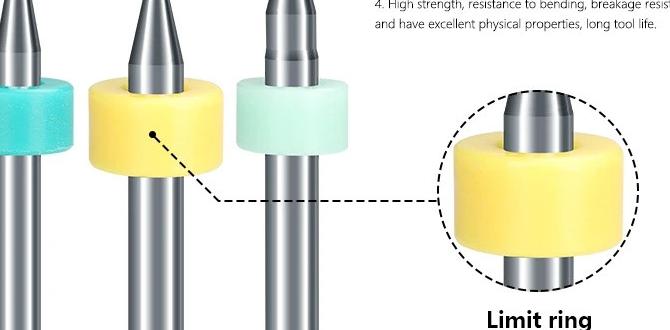

Description of key parts (e.g., spindle, tailstock, carriage). Functionality of each component in the setup.

CNC metal lathes are made up of several important parts. Each part has a special job that helps the machine work well. Here are the key components:

- Spindle: This is the part that spins the material. It holds the workpiece in place.

- Tailstock: This supports the other end of the material. It helps keep everything balanced.

- Carriage: This moves the tool across the material. It controls the cutting process.

Understanding these parts is crucial for setting up a CNC metal lathe correctly. Each one plays a vital role in shaping the metal.

What are the essential parts of a CNC metal lathe?

The essential parts are the spindle, tailstock, and carriage. Each part has a unique function to ensure precise metal shaping.

Preparing for the CNC Metal Lathe Setup

Necessary tools and equipment for setup. Safety precautions to consider before beginning.

Before starting the cnc metal lathe setup, gather all necessary tools and equipment. You will need items like a wrench, calipers, and safety goggles. Make sure everything is in working order. Safety is key, too. Always wear protective gear. Keep the workspace tidy to avoid accidents. Here are some items to check before you begin:

- Safety goggles

- Work gloves

- Ear protection

These precautions help keep you safe while you work. Prepare wisely for a smooth setup!

What tools do I need for CNC metal lathe setup?

You need a few basic tools, such as wrenches, calipers, and safety gear like goggles. This helps ensure an efficient and safe working environment.

Step-by-Step Guide to Setting Up a CNC Metal Lathe

Initial machine positioning and leveling. Configuring the CNC controller and software.

Setting up a CNC metal lathe is exciting! First, you need to place the machine on a flat surface. Use a level tool to check if it’s even. This step is crucial. An uneven machine can cause mistakes.

Next, configure the CNC controller and software. Make sure the software matches your machine. Follow the software’s instructions. Easily connect the controller to your PC. Test the connection to ensure everything works smoothly. Your lathe is now ready for action!

What are the steps for a CNC lathe setup?

The steps include leveling the machine and configuring the controller and software. This ensures the lathe runs correctly and safely.

Loading and Securing the Material

Best practices for choosing and preparing workpieces. Techniques for properly securing materials for operation.

Choosing the right material is key for good results. Start with clean workpieces. Remove dust and grease. Next, pick a strong material that fits your project’s needs. Common choices are aluminum and steel. Before you begin, secure the piece properly. Use clamps or a chuck to hold it tightly. This keeps the material steady while you work. A well-secured piece means a safer, smoother operation.

How do I prepare a workpiece for a CNC lathe?

To prepare a workpiece, **clean it thoroughly**, **check for damage**, and **cut it to the right size** for your lathe. These steps help ensure a smooth machining process.

Best Practices for Securing Materials

- Use clamps or vices firmly.

- Check alignment before starting.

- Regularly inspect for movement during machining.

Calibrating the CNC Metal Lathe

Importance of calibration for precision. Stepbystep calibration process.

Calibration is key for achieving precise results with your CNC metal lathe. A well-calibrated machine ensures accuracy, keeping your parts correct to the last bolt. Imagine making a piece that’s supposed to fit perfectly and finding out it’s a tiny bit too big – yikes! That’s where calibration saves the day.

Here’s a simple step-by-step process to calibrate your lathe:

| Step | Description |

|---|---|

| 1 | Check and clean the machine. |

| 2 | Set the tool height. |

| 3 | Adjust the spindle speed. |

| 4 | Run a test program. |

| 5 | Measure outputs and adjust as needed. |

Following these steps can significantly improve your work. Plus, you’ll look like a genius while you do it!

Common Issues and Troubleshooting Tips

Identifying common setup problems and their solutions. Tips for maintaining optimal performance.

Setting up a CNC metal lathe can be tricky. Many problems can arise, but they often have simple fixes. Check the alignment and make sure the tools are secure. Here are some common issues and tips to keep your lathe running well:

- 🔹 Unstable machining: Ensure the lathe is on a solid surface.

- 🔹 Tool wear: Replace tools regularly.

- 🔹 Inaccurate measurements: Double-check all settings before starting.

- 🔹 Overheating: Keep parts cool with proper lubrication.

By fixing these problems, you can improve performance and extend the lathe’s life.

What are some basic troubleshooting steps for a CNC metal lathe?

Basic troubleshooting steps include checking power connections, adjusting settings, and inspecting tools for damage.

Best Practices for CNC Metal Lathe Operation

Recommendations for operator efficiency and accuracy. Importance of regular maintenance routines.

Running a CNC metal lathe is like baking cookies; it requires the right ingredients and a proper recipe! For operator efficiency, always stay organized. Keep tools and materials close so you don’t spend more time searching than working. Regular maintenance is essential too; think of your lathe as a pet—it needs love and care! A simple checklist can help. Remember, even machines can get cranky!

| Maintenance Task | Frequency |

|---|---|

| Clean bed and tools | Daily |

| Check lubrication | Weekly |

| Inspect components | Monthly |

Take care of your lathe, and it will take care of you! This harmony leads to better accuracy and fewer hiccups. Happy lathe time!

Conclusion

In summary, setting up a CNC metal lathe involves understanding tools, software, and safety. You need to select the right machine and prepare your workspace carefully. Make sure to practice and test your settings. By following these steps, you can create precise metal parts. For more tips and tricks, explore tutorials or guides online! Happy machining!

FAQs

What Are The Essential Tools And Equipment Required For Setting Up A Cnc Metal Lathe?

To set up a CNC (Computer Numerical Control) metal lathe, you need a few important tools. First, you need a good power supply to run the machine. Next, you’ll need cutting tools to shape the metal. A tool holder helps keep the cutting tools in place. Finally, you should have safety gear like goggles and gloves to protect yourself while working.

How Do You Properly Align And Calibrate The Cnc Metal Lathe For Accurate Machining?

To align and calibrate a CNC metal lathe, first, make sure it is on a flat surface. You can check if it’s level by using a bubble level. Next, set the tools in the right place and tighten them so they don’t move. Then, run a test program and measure the results carefully. Adjust as needed, and keep testing until everything is perfect!

What Are The Key Parameters To Consider When Programming A Cnc Metal Lathe For Specific Workpieces?

When programming a CNC metal lathe, we need to think about a few important things. First, we should know the size and shape of the workpiece, which is the metal we’re shaping. Next, we need to choose the right speed to make clean cuts. It’s also important to pick the right tools for the job. Finally, we must set the correct depth of cut to avoid damaging the metal.

How Do You Select The Right Cutting Tools And Materials For A Cnc Metal Lathe Setup?

To pick the right cutting tools and materials for a CNC metal lathe, start by knowing your project. You need to match the tool to the metal you’re using. Choose tools that can cut through the metal easily. Also, check if the tool lasts a long time and stays sharp. This way, your work will be smoother and faster!

What Safety Precautions Should Be Taken During The Setup And Operation Of A Cnc Metal Lathe?

When using a CNC (Computer Numerical Control) metal lathe, we need to be very careful. Always wear safety glasses to protect your eyes. Keep long hair tied back and wear close-fitting clothes. Make sure the machine is turned off before you set it up or change parts. Finally, keep your hands away from moving parts to avoid getting hurt.