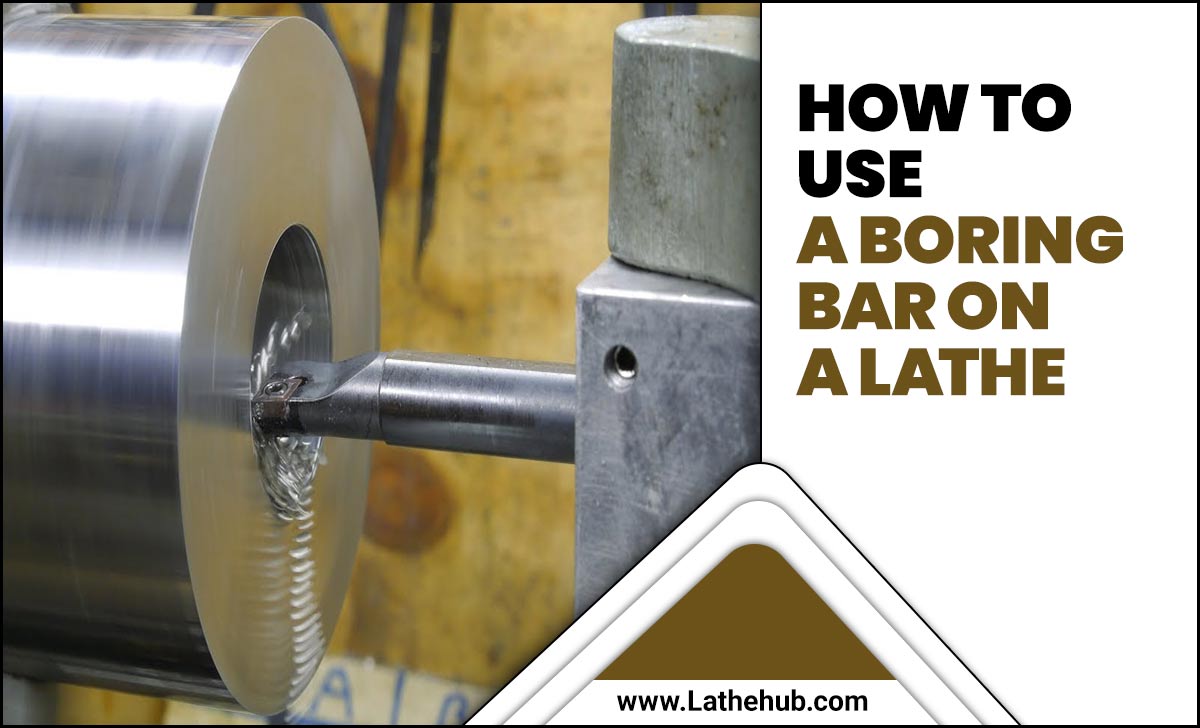

Have you ever wondered how metal parts are made for machines or tools? A small yet mighty machine called a lathe plays a big role in this process. A compact metal lathe bed is the backbone of that lathe. Without it, the machine wouldn’t work effectively.

Imagine a tiny workshop bustling with creativity. A person stands over their compact lathe, crafting pieces with precision. They can turn raw metal into beautiful shapes! Do you know what makes a compact metal lathe bed so special? It allows the lathe to be sturdy yet small, perfect for tight spaces.

Did you know that some compact lathes are so small they can fit on a desk? Many hobbyists love them! They can create everything from custom tools to model parts. It’s amazing how one little machine can spark so much creativity.

In this article, we will dive deeper into the world of compact metal lathe beds. We’ll explore what makes them important and how they can help anyone interested in metalworking.

Exploring The Benefits Of A Compact Metal Lathe Bed

Understanding Compact Metal Lathe Beds

A compact metal lathe bed is an essential part of a lathe machine. It holds the main components, ensuring stability and precise movement. With its smaller design, it fits well in tight spaces, making it perfect for hobbyists and professionals alike. Did you know that using a compact bed can improve your projects’ accuracy? Overall, investing in a high-quality lathe bed can enhance your metalworking skills, making tasks easier and more enjoyable.What is a Compact Metal Lathe Bed?

Definition and purpose of a compact metal lathe bed. Key features distinguishing it from traditional lathes.A compact metal lathe bed is a shorter, squatter version of the classic lathe. Think of it as the fun-sized candy bar of machinery! It holds the parts of the lathe securely while allowing it to shape metal pieces precisely. Unlike traditional lathes, these beds are lighter and occupy less space, making them perfect for small workshops or garages. Some key features include its durability, stability, and easy portability. You can whip up some impressive projects without needing a mansion-sized workshop!

| Feature | Compact Metal Lathe Bed | Traditional Lathe |

|---|---|---|

| Size | Smaller | Larger |

| Weight | Lighter | Heavier |

| Usability | Easy to move | Stationary |

Benefits of Using a Compact Metal Lathe Bed

Spacesaving advantages for small workshops. Increased precision and control in machining.A compact metal lathe bed is like having a tiny superhero in your workshop. It saves space, which is great for small areas where every inch counts. You can squeeze it in without feeling like you’re playing Tetris. Plus, it offers sharp accuracy in machining. This means you can make precise cuts, and not just chop away like a chef with a dull knife. Precision and control go hand in hand, making your projects look neat and professional—just like a rainbow after a storm!

| Advantage | Description |

|---|---|

| Space-Saving | Perfect for small workshops! Less clutter, more creativity. |

| Precision | Higher control means fewer mistakes. Who likes fixing oopsies? |

Choosing the Right Compact Metal Lathe Bed

Factors to consider: Size, weight capacity, and power requirements. Importance of user reviews and brand reputation.Picking a compact metal lathe bed is like choosing a comfy chair for a chess match: it needs to fit just right. First, think about size. You want it to fit in your workspace without taking over like a giant cat. Next, check the weight capacity—nobody wants a bed that folds under pressure, right? Power requirements matter too; make sure it matches your needs so you’re not left in the dark. Lastly, user reviews are gold! They spill the tea on what works well and what doesn’t. Remember, a strong brand reputation is like a reliable friend; they won’t let you down!

| Factor | Consideration |

|---|---|

| Size | Fit in your workspace without overwhelming it. |

| Weight Capacity | Don’t want it to collapse under a hefty load! |

| Power Requirements | Match it to your needs for smooth operation. |

| User Reviews | Listen to what others say; their experience is valuable. |

| Brand Reputation | Choose a brand that’s trusted and reliable. |

Setup and Installation of a Compact Metal Lathe Bed

Stepbystep guide to setting up the lathe. Common mistakes to avoid during installation.Setting up a compact metal lathe bed doesn’t have to be as tricky as threading a needle in a hurricane! First, find a sturdy surface to place it on. Level it out, or your projects might wobble like a jelly. Next, assemble parts by following the manual. Don’t skip steps—it’s not a scavenger hunt!

Common mistakes include not tightening screws and misaligning components. Both can turn your lathe into a fancy paperweight. Remember, a happy lathe makes smooth cuts!

| Common Mistakes | Tips to Avoid |

|---|---|

| Not leveling the bed | Use a spirit level! |

| Loose screws | Tighten everything before use. |

Maintenance Tips for Compact Metal Lathe Beds

Daily, weekly, and monthly maintenance routines. Troubleshooting common issues.Regular care keeps your compact metal lathe bed in good shape. Follow these simple routines:

- Daily: Clean off dust and grease after use.

- Weekly: Check for loose screws. Tighten them if needed.

- Monthly: Lubricate moving parts and inspect for wear.

If your lathe has problems, check these common issues:

- Unusual noises could mean parts need lubrication.

- It might vibrate if the bed is not level. Adjust it.

- Inaccurate cuts could be from dull tools. Replace them.

Taking these steps will keep your machine running smoothly!

What are some common issues with compact metal lathe beds?

Common issues include vibrations, noise, and inaccurate cuts. Regular maintenance can help solve these problems.

Upgrades and Accessories for Compact Metal Lathes

Recommended upgrades to enhance functionality. Essential accessories for maximizing productivity.To make your compact metal lathe even better, consider these helpful upgrades and accessories. They boost how well your lathe works and can save you time. Here are some suggestions:

- Upgrade your tools: High-speed steel tools cut more smoothly.

- Add a quick-change tool post: This lets you switch tools fast.

- Install a digital readout: It helps with precise measurements.

Also, some key accessories can help you work better:

- Toolboxes: Keep your tools organized.

- Chip trays: Manage debris easily.

- Cutting oils: Keep your tools lubricated for better cuts.

Upgrading and adding the right tools can make your work fun and efficient. With these smart choices, you’ll get better results in your projects!

What are some easy upgrades for compact metal lathes?

Upgrading your lathe tools can boost performance. Quick-change tool posts and digital readouts also improve accuracy and efficiency. These upgrades make a significant difference in your metalworking experience.

Cost Considerations for Compact Metal Lathe Beds

Average price ranges for different models. Longterm investment value analysis.Buying a compact metal lathe bed can vary in cost. Prices usually range from $500 to $5000, depending on the model. A more expensive model may have extra features or better quality. Think of it as a long-term investment. It can last for many years, making it worth the price. If you use it often, a higher-priced lathe may save you money over time. Think about your needs and what will work best for you.

How much should you expect to spend on a compact metal lathe bed?

The average cost can be between $500 and $5000. This difference depends on the brand and features included.

What are the benefits of investing in a better model?

- Better quality materials

- More features that improve usability

- Longer lifespan and better performance

Conclusion

In summary, a compact metal lathe bed is crucial for precision and stability in machining. It saves space, making it perfect for smaller workshops. We recommend exploring different brands and models to find what suits your needs best. By learning more about lathes, you can improve your skills and create amazing projects. Keep discovering and practicing!FAQs

What Are The Key Features Of A Compact Metal Lathe Bed That Make It Suitable For Hobbyists And Small Workshops?A compact metal lathe bed is perfect for hobbyists and small workshops because it saves space. It is smaller and lighter, making it easier to move around. The bed is strong and sturdy, helping you make precise parts. It also has simple controls, so you can learn quickly. This makes it fun to use for many projects!

How Does The Rigidity Of A Compact Metal Lathe Bed Affect Machining Accuracy And Finish Quality?A compact metal lathe bed needs to be very stiff. If it bends or shakes, the machine won’t cut straight. This means your final piece might be uneven or rough. A strong bed helps you make smooth and precise shapes. So, it’s important for making good quality work!

What Materials Are Typically Used In The Construction Of Compact Metal Lathe Beds, And How Do They Impact Durability?Compact metal lathe beds are usually made from cast iron or steel. Cast iron is heavy and very strong. Steel is tough and can resist bending. These materials help the lathe last a long time, even when used a lot. Strong materials keep the lathe steady and working well.

How Can Users Effectively Maintain And Care For A Compact Metal Lathe Bed To Ensure Longevity And Optimal Performance?To take good care of your compact metal lathe bed, keep it clean and dry. Wipe it down with a soft cloth after each use to remove dirt and oil. You should also check for any rust. If you see any, use a gentle rust remover. Lastly, make sure to oil moving parts as needed to keep everything running smoothly.

What Brands Or Models Of Compact Metal Lathes Are Highly Recommended Based On User Reviews And Machining Capabilities?Some great compact metal lathes to look at are the Sieg C2 and the Grizzly G8688. They get good ratings from people who use them. The Mini Lathe is also popular because it’s small and easy to use. You can make lots of cool things with these lathes. We like them because they work well for both beginners and experts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features Of A Compact Metal Lathe Bed That Make It Suitable For Hobbyists And Small Workshops? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact metal lathe bed is perfect for hobbyists and small workshops because it saves space. It is smaller and lighter, making it easier to move around. The bed is strong and sturdy, helping you make precise parts. It also has simple controls, so you can learn quickly. This makes it fun to use for many projects!”}},{“@type”: “Question”,”name”: “How Does The Rigidity Of A Compact Metal Lathe Bed Affect Machining Accuracy And Finish Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact metal lathe bed needs to be very stiff. If it bends or shakes, the machine won’t cut straight. This means your final piece might be uneven or rough. A strong bed helps you make smooth and precise shapes. So, it’s important for making good quality work!”}},{“@type”: “Question”,”name”: “What Materials Are Typically Used In The Construction Of Compact Metal Lathe Beds, And How Do They Impact Durability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Compact metal lathe beds are usually made from cast iron or steel. Cast iron is heavy and very strong. Steel is tough and can resist bending. These materials help the lathe last a long time, even when used a lot. Strong materials keep the lathe steady and working well.”}},{“@type”: “Question”,”name”: “How Can Users Effectively Maintain And Care For A Compact Metal Lathe Bed To Ensure Longevity And Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take good care of your compact metal lathe bed, keep it clean and dry. Wipe it down with a soft cloth after each use to remove dirt and oil. You should also check for any rust. If you see any, use a gentle rust remover. Lastly, make sure to oil moving parts as needed to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Brands Or Models Of Compact Metal Lathes Are Highly Recommended Based On User Reviews And Machining Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some great compact metal lathes to look at are the Sieg C2 and the Grizzly G8688. They get good ratings from people who use them. The Mini Lathe is also popular because it’s small and easy to use. You can make lots of cool things with these lathes. We like them because they work well for both beginners and experts!”}}]}