Have you ever wondered how a small machine can create such precise shapes? Enter the compact metal lathe. This handy tool is perfect for many projects, from crafts to repairs. One key part of this machine is the compact metal lathe belt.

Imagine working on a small piece of metal, shaping it just the way you want. The metal lathe belt plays a big role in making that happen smoothly. It’s what connects the motor to the spinning tool. Without it, things could get a bit messy!

Did you know that choosing the right compact metal lathe belt can improve your work quality? It can make your lathe run better and last longer. So, what should you look for when picking the perfect belt? Let’s dive deeper and find out more!

Compact Metal Lathe Belt: Enhance Your Machining Efficiency

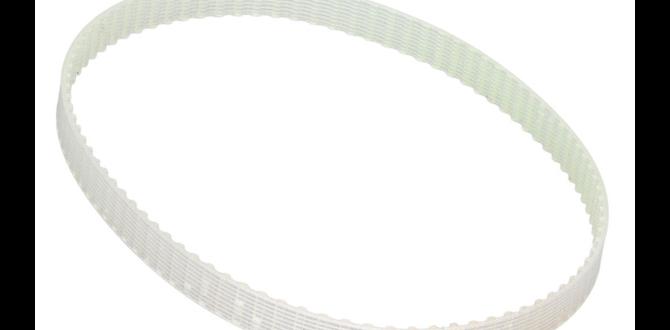

Compact Metal Lathe Belt

Choosing the right compact metal lathe belt can make a big difference in your projects. These belts help machines run smoothly and efficiently. Imagine creating perfect shapes and designs without interruption. A quality belt reduces wear and tear, saving time and money. Plus, it’s fun to see your ideas come to life! When selecting a belt, consider durability and compatibility with your lathe. Small details can lead to great results in your metalworking adventures.Understanding Compact Metal Lathes

Definition and purpose of compact metal lathes. Key features that distinguish compact models from larger lathes.Compact metal lathes are small machines that help you shape and cut metal. They do this by spinning the metal while cutting tools shape it. These machines are perfect for hobbyists and small workshops, saving space without sacrificing power. Key features that make them stand out include their size and precision. They fit into corners like a cat in a sunny spot. Compact lathes often come with a built-in motor, making them both convenient and quiet, like a ninja in the night!

| Feature | Compact Metal Lathe | Large Metal Lathe |

|---|---|---|

| Size | Small and easy to fit | Large and takes up space |

| Precision | High | Very high |

| Weight | Light | Heavy |

Importance of the Belt in Compact Metal Lathes

Role of the belt in operation and performance. Common materials and types of belts used in compact lathes.The belt in a compact metal lathe is like the magician’s wand—it makes everything work smoothly. It powers the machine and ensures that the parts rotate at the right speed. Without a good belt, your lathe might just sit there looking lost, like a puppy in a park without its owner! Common materials for these belts include rubber and polyurethane. Various types exist, like timing belts and flat belts, each playing their unique part.

| Type of Belt | Material | Use |

|---|---|---|

| Timing Belt | Rubber | Precise movements |

| Flat Belt | Polyurethane | Power transfer |

In many ways, the belt is the hero of the lathe’s story. It keeps everything moving and prevents disasters, like a superhero catching a falling balloon! Remember, a strong belt means a happy lathe.

Choosing the Right Belt for Your Compact Metal Lathe

Factors to consider: size, material, and compatibility. Comparing OEM belts vs. aftermarket options.Finding the perfect belt for your compact metal lathe can feel like picking the right pizza topping—there’s a lot to consider! First, focus on size and material. The belt must fit your lathe precisely to work well. Remember, a belt that’s too loose or too tight is like trying to wear shoes a size too big or too small—definitely not comfortable!

Next, think about compatibility. Some belts come straight from the manufacturer, known as OEM belts, while others are aftermarket options. OEM belts are like designer jeans, often more expensive but great quality. Aftermarket belts can save you cash, and if you’re lucky, you might find one that’s just as good at a fraction of the price. Don’t forget to check if it’s still a snug fit!

Here’s a quick comparison:

| Type | Price | Quality | Availability |

|---|---|---|---|

| OEM Belt | Higher | Excellent | Limited |

| Aftermarket Belt | Lower | Good | Widely Available |

In the end, whether you’re Team OEM or Team Aftermarket, just choose wisely and your lathe will thank you!

Signs Your Compact Metal Lathe Belt Needs Replacement

Visual indicators of wear and tear. Performance issues linked to a failing belt.When your compact metal lathe belt starts to say “I’m tired,” look for signs of wear and tear. If you spot cracks, fraying, or shiny spots, it’s time to take action. Don’t wait until the belt calls it quits on you! Performance issues might sneak in, like the lathe stalling or making funny noises. Trust me; you don’t want your machine going “uh-oh.” Below is a quick guide:

| Signs of a Worn Belt | Performance Issues |

|---|---|

| Cracks or splits | Lathe slows down |

| Fraying edges | Unusual noises |

| Shiny spots | Inconsistent cuts |

Keep an eye on these signs, and your lathe will thank you with smooth operations!

How to Replace the Belt on Your Compact Metal Lathe

Stepbystep guide to safe belt replacement. Tools and safety precautions required.Replacing the belt on your compact metal lathe isn’t rocket science, but it does need some care. First, gather your tools: a wrench, screwdriver, and a new belt. Always wear safety glasses! To start, unplug the lathe. Then, remove the cover to access the belt. Follow these simple steps:

| Step | Action |

|---|---|

| 1 | Unplug the lathe for safety. |

| 2 | Remove the old belt carefully. |

| 3 | Install the new belt, making sure it fits snugly. |

| 4 | Reattach the cover and plug the lathe back in. |

Now you’re ready to get back to work! Remember, safety first. If a stubborn belt gives you trouble, a slight kick might help—but let’s keep that for the last resort! Happy turning!

Maintaining Your Compact Metal Lathe Belt

Routine checks and maintenance tips. How to extend the lifespan of your lathe belt.Regular upkeep can keep your compact metal lathe belt in great shape. Check it for wear and tear often—think of it like checking your shoes for holes. A belt in good condition lasts longer and works better. Keep it clean to prevent dust from causing trouble, and don’t forget to adjust the tension. A loose belt is like a pair of saggy pants—no one wants that! Here’s a quick table for maintenance tips:

| Task | Frequency |

|---|---|

| Visual Check | Weekly |

| Tightness Adjustment | Monthly |

| Cleaning | Every 3 Months |

Following these tips can help extend the lifespan of your lathe belt. Remember, a happy belt means a happy lathe!

Upgrading Your Compact Metal Lathe Belt

Benefits of upgrading to higher quality belts. Considerations for selecting upgraded options.Upgrading to a higher-quality belt can be a game changer for your compact metal lathe. A strong belt ensures smoother operations and can help avoid those awkward “uh-oh” moments during projects. Better belts last longer and keep your machines humming. When choosing one, think about the materials and the fit. A belt that’s too loose may throw a wrench in your plans—literally! So, don’t hesitate to invest in quality. Your lathe will thank you!

| Benefits | Considerations |

|---|---|

| Improved performance | Material quality |

| Longer lifespan | Correct sizing |

| Less vibration | Installation ease |

Frequently Asked Questions about Compact Metal Lathe Belts

Common concerns and troubleshooting tips. Expert advice and recommendations on belt care.Many people wonder about the lifespan of a compact metal lathe belt. A good belt can last several years with proper care. It’s important to check for any signs of wear, like cracks or frays. Remember, a happy belt is a working belt! If you notice unusual sounds, it could be time for troubleshooting. Always make sure to adjust the tension. Too loose or too tight can cause problems! Here are some quick tips:

| Tip | Details |

|---|---|

| Check Regularly | Look for wear and tear. |

| Adjust Tension | Make sure it’s just right! |

| Keep Clean | Dust and oil can cause problems. |

Following these tips will make your lathe belt last longer. After all, nobody wants their tools to throw a tantrum!

Conclusion

In summary, a compact metal lathe belt is essential for smooth machine operation. It helps you shape and cut metal accurately. Regularly check and maintain your belt for better performance. Consider reading more about choosing the right lathe and its parts. With the right tools, you’ll become a skilled maker. Start exploring and enjoy your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Belts:Compact metal lathe belts are important parts of a lathe machine. They help turn the lathe so you can shape metal. If the belt wears out, it can stop the machine from working. You should check your belt regularly to make sure it’s strong. If you need to replace it, ask an adult for help!

Of course! Just ask your question, and I’ll give you a short, simple answer.

What Are The Key Factors To Consider When Selecting A Belt For A Compact Metal Lathe?When picking a belt for a compact metal lathe, you should think about three main things. First, check the size of the belt. It needs to fit your lathe perfectly. Second, look at the strength of the belt. It should be strong enough to handle heavy work. Lastly, consider the material. Some materials last longer and work better for machines.

How Often Should The Belt On A Compact Metal Lathe Be Inspected Or Replaced To Ensure Optimal Performance?You should check the belt on your compact metal lathe every few months. Look for signs of wear, like cracks or fraying. If you see these signs, it’s time to replace the belt. Keeping the belt in good shape helps the lathe work better and last longer. Always remember to check it before you start using the machine.

What Are The Common Types Of Belts Used In Compact Metal Lathes, And How Do They Differ In Terms Of Material And Function?Compact metal lathes usually use rubber belts, flat belts, and V-belts. Rubber belts are flexible and help move parts smoothly. Flat belts are wide and can handle heavy loads, while V-belts have a shape that prevents slipping. Each type helps the lathe work better, but they are made from different materials for different jobs.

How Can Belt Tension Be Properly Adjusted On A Compact Metal Lathe To Prevent Slippage And Maintain Accurate Machining?To adjust the belt tension on a compact metal lathe, first, find the tension adjustment screws. You can loosen these screws to make changes. Then, pull the belt slightly to tighten it and avoid slippage. After adjusting, tighten the screws again to keep the belt in place. Check if the belt feels firm and not too loose. This helps in making sure your machine works well.

What Are Some Common Issues That Can Arise With The Belts On Compact Metal Lathes, And What Steps Can Be Taken To Troubleshoot And Resolve Them?Belts on compact metal lathes can have a few problems. They might get loose, worn out, or broken. First, check if the belt is tight. If it’s loose, you can adjust it. If it’s worn or broken, you should replace it with a new one. Always remember to turn off the lathe before making any changes!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Belts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Compact metal lathe belts are important parts of a lathe machine. They help turn the lathe so you can shape metal. If the belt wears out, it can stop the machine from working. You should check your belt regularly to make sure it’s strong. If you need to replace it, ask an adult for help!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Just ask your question, and I’ll give you a short, simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Belt For A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a belt for a compact metal lathe, you should think about three main things. First, check the size of the belt. It needs to fit your lathe perfectly. Second, look at the strength of the belt. It should be strong enough to handle heavy work. Lastly, consider the material. Some materials last longer and work better for machines.”}},{“@type”: “Question”,”name”: “How Often Should The Belt On A Compact Metal Lathe Be Inspected Or Replaced To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the belt on your compact metal lathe every few months. Look for signs of wear, like cracks or fraying. If you see these signs, it’s time to replace the belt. Keeping the belt in good shape helps the lathe work better and last longer. Always remember to check it before you start using the machine.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Belts Used In Compact Metal Lathes, And How Do They Differ In Terms Of Material And Function?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Compact metal lathes usually use rubber belts, flat belts, and V-belts. Rubber belts are flexible and help move parts smoothly. Flat belts are wide and can handle heavy loads, while V-belts have a shape that prevents slipping. Each type helps the lathe work better, but they are made from different materials for different jobs.”}},{“@type”: “Question”,”name”: “How Can Belt Tension Be Properly Adjusted On A Compact Metal Lathe To Prevent Slippage And Maintain Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the belt tension on a compact metal lathe, first, find the tension adjustment screws. You can loosen these screws to make changes. Then, pull the belt slightly to tighten it and avoid slippage. After adjusting, tighten the screws again to keep the belt in place. Check if the belt feels firm and not too loose. This helps in making sure your machine works well.”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise With The Belts On Compact Metal Lathes, And What Steps Can Be Taken To Troubleshoot And Resolve Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Belts on compact metal lathes can have a few problems. They might get loose, worn out, or broken. First, check if the belt is tight. If it’s loose, you can adjust it. If it’s worn or broken, you should replace it with a new one. Always remember to turn off the lathe before making any changes!”}}]}