Have you ever wondered how a compact metal lathe can shape metal with precision? A simple device called a controller board makes this possible. These boards control the lathe’s movements, turning raw metal into beautiful creations.

Imagine you’re in a workshop, and you see metal rods spinning smoothly. The magic happens thanks to the compact metal lathe controller board. It guides the tools with amazing accuracy, making complex shapes easy to create.

Did you know that even small lathes can achieve professional-level results? With the right controller board, hobbyists and professionals alike can transform their ideas into reality. Whether you’re building models or parts, a great controller board makes all the difference.

In this article, we will dive deeper into how these boards work and what makes them so special. Get ready to uncover the secrets behind the compact metal lathe controller board!

Compact Metal Lathe Controller Board: An Essential Guide

Exploring the Compact Metal Lathe Controller Board

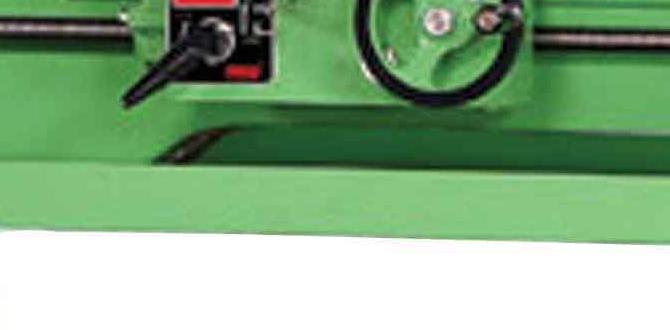

Discover the compact metal lathe controller board, a key tool for hobbyists and professionals alike. This device allows you to control the lathe’s movements precisely. Imagine turning raw metal into beautiful parts effortlessly! A good controller board enhances your lathe’s performance, making it easier to create intricate designs. Did you know some boards even connect to computers, enabling advanced programming? With the right controller, your metalworking projects can turn out just as you imagined!What is a Compact Metal Lathe Controller Board?

Definition and purpose of a controller board in metal lathes. Comparison of compact controller boards versus traditional designs.A compact metal lathe controller board is a small device that helps control a metal lathe, which is a machine tool used to shape metal. The purpose of this board is to manage the lathe’s movements and functions, making it easier for users to create precise items.

Compared to traditional designs, compact controller boards are smaller and often easier to use. They have advanced features that improve performance and save space. Here are some key differences:

- Size: Compact boards take less room.

- Ease of Use: They are user-friendly.

- Advanced Features: Many have built-in programs for specific tasks.

Using a compact controller board can make metalworking fun and efficient. With these advancements, makers can enjoy improving their projects with great control.

What advantages does a compact metal lathe controller board offer?

Compact controller boards offer better space-saving design, user-friendly controls, and additional features that improve metalworking accuracy and efficiency.

Key Features of Compact Metal Lathe Controller Boards

Essential specifications to look for. Common functionalities and capabilities.When choosing a compact metal lathe controller board, it’s important to know its key features. Look for specifications that fit your needs. Here are some essential features:

- Compatibility: Ensure it matches your lathe model.

- Power Output: Check how much power it can manage.

- Size: It should fit in your workspace easily.

Common functionalities include:

- Speed Control: Easily adjust the lathe speed.

- Setup Routines: Simple steps for quick setup.

- Emergency Stop: Safety features for quick shutdown.

Understanding these points makes it easier to pick the right controller board for your lathe project!

What should I look for in a compact metal lathe controller board?

Look for compatibility, power output, and ease of use to make the best choice.

Benefits of Using a Compact Metal Lathe Controller Board

Spacesaving advantages. Enhanced precision and control in machining operations.Choosing a compact metal lathe controller board really makes life easier. First, it saves precious space in your workshop. Imagine fitting all your tools without turning your workspace into a maze! Also, these controllers boost precision and give you amazing control while machining. Your projects will look sharper than a tack! With such benefits, you’ll feel like a crafting wizard. So, ready to be the master of your lathe?

| Benefit | Description |

|---|---|

| Space-Saving | Less clutter means more room for creativity! |

| Enhanced Precision | Make everything fit and finish perfectly! |

| Better Control | Master any project like a pro. |

How to Choose the Right Compact Metal Lathe Controller Board

Factors to consider: compatibility, performance, and budget. Recommended brands and models in the market.Choosing the right compact metal lathe controller board can be easy if you focus on the key factors. First, check for compatibility with your lathe. Make sure it will fit well and work smoothly. Next, consider performance. Look for boards that offer precise control and speed settings. Finally, set a budget. High-quality boards can vary in price, so find one that fits your wallet.

Some recommended brands include:

- Mach3

- cnc4you

- Syntec

These options are popular and reliable, making your choice simpler!

What to consider when buying a compact metal lathe controller board?

Look for features like easy setup, fast response time, and good user reviews. These aspects will help ensure you get the best board for your needs.

Installation Guide for Compact Metal Lathe Controller Boards

Stepbystep installation process. Common installation challenges and troubleshooting tips.Installing a compact metal lathe controller board can be simple and fun, like assembling a puzzle. Start by gathering all your tools. Connect the wires according to the diagram. Don’t worry if you feel like a confused squirrel at this stage; check the manual for help! Here’s a handy troubleshooting table:

| Issue | Solution |

|---|---|

| No power | Check the power supply connections. |

| Unresponsive controls | Make sure all cables are plugged in securely. |

| Erratic movements | Calibrate the settings in the software. |

With patience, you’ll have your lathe dancing in no time! Remember, the only thing spinning in frustration should be your lathe tool, not you!

Maintenance Tips for Compact Metal Lathe Controller Boards

Routine checks and procedures to ensure longevity. Signs of wear and when to replace components.Keeping your compact metal lathe controller board in good shape is important. Regular checks help it last longer. Look for dust or loose wires. If you see wear, it might be time to replace parts. Here are a few easy procedures:

- Check connections monthly.

- Clean dust weekly.

- Listen for strange noises.

A sign of trouble could be blinking lights or no response. Don’t wait if something seems off.

What are the signs that your controller board needs replacing?

Common signs include flickering displays or unresponsive controls. If these happen, it’s time to check your board closely and consider replacing it!

Real-World Applications of Compact Metal Lathe Controller Boards

Industries that benefit from using these boards. Case studies or examples of successful implementations.Many industries, like manufacturing and automotive, thrive with compact metal lathe controller boards. These clever devices help machinery run smoothly, turning raw materials into amazing products. For example, a small car part factory improved its production speed by 30% after upgrading to these boards. Talk about zooming past the competition!

| Industry | Benefit |

|---|---|

| Manufacturing | Boosts efficiency |

| Automotive | Enhances precision |

| Jewelry | Crafts detailed designs |

In the world of crafts, artisans love these boards for making beautiful jewelry. The versatility of compact metal lathe controller boards makes them beloved tools. They take ordinary metal and turn it into treasures, making creativity fun! Who knew machines could be so cool?

Future Trends in Compact Metal Lathe Controller Boards

Emerging technologies and innovations. Predictions for the evolution of controller boards over the next decade.New ideas are coming for compact metal lathe controller boards! Smart tech, like AI and IoT, will make these boards better. In the next decade, we might see:

- Faster processing speed

- Smaller sizes

- More accurate tools

- User-friendly software

These changes mean users can create more complex designs easily. Exciting times are ahead!

What innovations can we expect in controller boards?

Innovations like AI integration and touch-screen interfaces will enhance usability and precision.

Why will these trends matter?

These trends will make machining faster and more efficient, opening doors for hobbyists and professionals alike!

Conclusion

In summary, a compact metal lathe controller board is essential for precise machining. It helps you control the lathe easily and improves your projects. By using one, you can enhance your skills and create better parts. We encourage you to explore different models and read user reviews. This way, you can find the best controller board for your needs!FAQs

What Are The Essential Features To Look For In A Compact Metal Lathe Controller Board To Ensure Compatibility With Various Lathe Models?When choosing a controller board for a compact metal lathe, look for a few important features. First, make sure it works with different motors. Next, check if it has adjustable settings for speed and power. You should also see if it connects easily to your lathe. Lastly, pick a board with good support and instructions to help you set it up.

How Do Different Types Of Controller Boards Impact The Performance And Precision Of A Compact Metal Lathe?Different controller boards control how a compact metal lathe works. Some boards help it move smoothly and quickly, making better cuts. Others might be slower, which can lead to rough surfaces. When you choose a better controller board, you get more accurate shapes and sizes. This makes your projects turn out just right!

What Safety Measures Should Be Considered When Installing And Using A Compact Metal Lathe Controller Board?When setting up your lathe controller board, always wear safety glasses to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Make sure the lathe is unplugged while you work on it. Lastly, double-check all connections before turning it on to prevent any accidents. Stay safe and always ask an adult for help if you’re unsure!

How Can A Compact Metal Lathe Controller Board Be Integrated With Cnc Systems For Automated Machining Processes?You can connect a compact metal lathe controller board to a CNC (Computer Numerical Control) system using wires. First, make sure the board understands commands from the computer. Then, we send instructions to tell the lathe what to do. This helps machines work automatically, making parts faster and more accurately. It’s like teaching your machine how to build things by itself!

What Are The Common Troubleshooting Steps For Issues Encountered With Compact Metal Lathe Controller Boards?To fix problems with a metal lathe controller board, first, check the power supply. Make sure it’s plugged in and working. Next, look for any loose wires or connections that might need tightening. You can also reset the controller by turning it off and on again. If it still doesn’t work, checking the user manual can help, or you might need to ask for help.