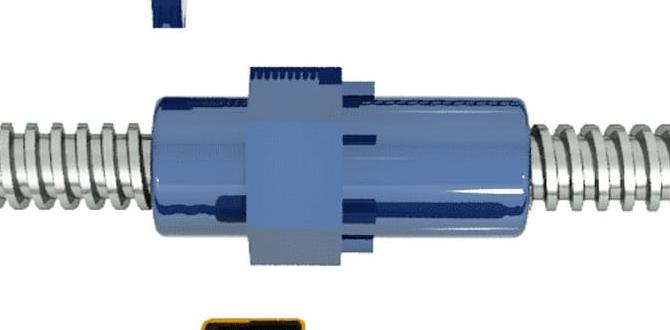

Have you ever wondered how machines create precise parts? One key component is the lead screw. When building a compact metal lathe, choosing the right lead screw is important.

A lead screw helps move the tool in a smooth and controlled way. This means every turn of the lathe can make accurate cuts. Imagine making a tiny part for a robot or a model car. The right lead screw can make all the difference in getting it just right.

Did you know that a well-designed lead screw can last many years? Some skilled makers even say it’s the secret to a great lathe. Whether you’re a hobbyist or a pro, understanding the lead screw can help you achieve better results.

So, what makes a lead screw so special in a compact metal lathe? Let’s dive into the details and discover its magic!

Compact Metal Lathe Lead Screw: Essential Turning Tool Insights

Understanding the Compact Metal Lathe Lead Screw

A compact metal lathe lead screw is an essential component that helps control the movement of the lathe. It allows for precise cutting and shaping of metal. This screw is often found in small lathes, ideal for hobbyists and small workshops. Did you know that the accuracy of your cuts can depend heavily on this simple part? Learning about the lead screw can greatly improve your machining skills and the quality of your projects. With proper care, it can last a long time, ensuring smooth operation.What is a Compact Metal Lathe Lead Screw?

Definition and purpose of a lead screw in metal lathes. Differences between compact and traditional lead screws.A lead screw is a vital part of a metal lathe. It helps move the cutting tool precisely along the workpiece. This ensures smooth and accurate cuts. Compact metal lathe lead screws are smaller and lighter than traditional ones. This makes them easier to handle without losing strength. Here are some key differences:

- Size: Compact lead screws are smaller, making them fit in tight spaces.

- Weight: They are lighter, which is good for easy upgrades.

- Durability: Both types are strong, but compact screws are designed for portability.

Overall, compact lead screws are perfect for small shops and DIY projects.

What is a lead screw in a metal lathe?

A lead screw in a metal lathe is a threaded rod that moves the cutting tool to create precise shapes.

Benefits of Using a Compact Metal Lathe Lead Screw

Advantages of compact design in various applications. Precision and efficiency in machining processes.Using a compact metal lathe lead screw comes with many perks. First, its small design fits easily in tight spaces. This is perfect for hobbyists and professionals alike. Next, it enhances precision and efficiency in machining. This means you can create parts that fit together like puzzle pieces. Statistics show that efficient machining can soar productivity by up to 30%. It’s like having a mini robot that doesn’t complain about overtime! So whether you’re crafting small models or big projects, a compact lead screw is a game-changer.

| Benefits | Description |

|---|---|

| Compact Design | Fits in small spaces, ideal for various applications. |

| Precision | Helps produce parts with high accuracy. |

| Efficiency | Improves workflow and productivity by up to 30%! |

Factors to Consider When Choosing a Lead Screw

Load capacity and torque specifications. Compatibility with existing lathe models.Choosing the right lead screw is like picking your favorite ice cream flavor—there are many factors! First up is load capacity and torque specifications. Make sure your lead screw can handle the weight of your projects, or it may feel like it’s lifting a mountain! Compatibility with your lathe model is also key. You wouldn’t want a lead screw that’s like a square peg in a round hole, right? Checking these details ensures smooth sailing in your workshop.

| Factor | Description |

|---|---|

| Load Capacity | The weight the lead screw can support without bending. |

| Torque Specifications | The twisting force needed for proper operation. |

| Compatibility | How well it fits with your current lathe model. |

Installation and Maintenance Tips for Lead Screws

Stepbystep installation guide. Regular maintenance practices to ensure longevity.Installing a lead screw is easier than finding socks that match! Start by carefully aligning it with the lathe. Use the right tools, like your trusty wrench, and tighten it snugly. Don’t be too harsh; we don’t want to break anything! For regular maintenance, check for wear and tear. Clean it often to keep out dirt and grime. Lubricate it to ensure smooth operation. Remember, a happy lead screw means a happy lathe!

| Maintenance Tips | Frequency |

|---|---|

| Inspect for wear | Monthly |

| Clean surfaces | Weekly |

| Lubricate parts | Bi-weekly |

Common Issues and Troubleshooting for Lead Screws

Identifying and resolving common problems. Signs of wear and when to replace.Lead screws can face issues that affect their performance. Common problems include unusual sounds or vibrations. These signs indicate that something is wrong. If you notice uneven movement, it’s time to check the lead screw. Look for wear, such as rust, grooves, or a bent shape. If the wear is serious, you may need to replace the lead screw. Regular maintenance helps prevent many issues.

What are signs of a worn lead screw?

Look for rust, inconsistent movement, or strange noises. These signals often mean the lead screw is wearing out and needs your attention.

How to identify common lead screw problems?

- Listen for rattling or grinding sounds.

- Look for visible wear or damage.

- Check for smooth operation and straight alignment.

Upgrading Your Compact Metal Lathe with a New Lead Screw

Signs that an upgrade is needed. Best practices for selecting a new lead screw.Is your compact metal lathe feeling a bit sluggish? That might be a sign you need a new lead screw. Look for wear and tear, like rusty threads or slipping movements. If your projects aren’t coming out as smooth as a baby’s bottom, it’s time to upgrade!

When picking a new lead screw, consider size and material. A good lead screw should be sturdy but not too heavy, like a great dancer! Here’s a helpful table:

| Factor | What to Look For |

|---|---|

| Length | Matches your lathe |

| Material | Strong yet lightweight |

| Threads | Compatible with your current setup |

Remember, choosing the right lead screw is like picking the right socks—when it fits right, everything works better!

Real-World Applications of Compact Metal Lathe Lead Screws

Industries that benefit from compact metal lathes. Case studies showcasing successful implementations.Many industries find compact metal lathes and their lead screws quite useful. For starters, the automotive sector uses them to craft precision components. Even small businesses, like local machine shops, rely on these tools to produce custom parts. Picture this: a tiny machine creating gears that fit perfectly in a car. It’s like a perfect puzzle piece!

| Industry | Application |

|---|---|

| Automotive | Precision parts production |

| Aerospace | Lightweight components |

| Manufacturing | Custom tooling |

Case studies show that companies using compact metal lathes greatly improve their output quality. For example, a small workshop doubled its production rate by upgrading to a metal lathe. Their shop now runs smoother than a greased weasel! Compact metal lathes help industries run efficiently and creatively.

Future Trends in Compact Metal Lathe Technology

Innovations in lead screw design and materials. Predictions for the future of metal machining technology.Exciting things are happening in compact metal lathe technology! Innovations in lead screw design are making these machines more precise. New materials, like carbon fiber, are lighter and stronger, leading to smoother operations. Experts predict that automated features will soon make metal machining easier than ever. So, say goodbye to clunky old machines! Future lathes might even be smart enough to think for themselves—like your pet cat, but without the attitude.

| Innovation | Description |

|---|---|

| Advanced Lead Screws | Lighter and stronger materials for better performance. |

| Automation | Machines that do more tasks by themselves. |

| Smart Technology | Future lathes with advanced sensors and features. |

Conclusion

In summary, a compact metal lathe lead screw is vital for precise machining. It helps you make accurate cuts and shapes in metal. Understanding its function improves your projects. We encourage you to explore more about lathes and their parts. Dive deeper into resources or hands-on practice to enhance your skills. Happy machining!FAQs

What Is The Purpose Of The Lead Screw In A Compact Metal Lathe, And How Does It Impact Machining Precision?The lead screw is a long, threaded rod in a metal lathe. It helps move the cutting tool smoothly. This movement allows us to make very precise cuts. When the lead screw works well, our finished pieces fit perfectly. That’s how it makes our work better!

What Are The Common Materials Used For Manufacturing Lead Screws In Compact Metal Lathes, And What Are Their Advantages?Common materials for making lead screws in compact metal lathes are steel, brass, and plastic. Steel is strong and lasts a long time. Brass is smooth and helps reduce friction. Plastic is lighter and can be cheaper, but it may not be as strong. Each material has good points that help in different tasks.

How Can The Lead Screw Be Maintained Or Adjusted To Ensure Smooth Operation On A Compact Metal Lathe?To keep the lead screw working well on a metal lathe, you should clean it often. Use a soft cloth to wipe away dirt and old oil. Next, check if it needs more oil. You can add a little machine oil to help it run smoothly. If it feels loose, you can tighten the screws to make it snug again.

What Are The Typical Dimensions And Specifications Of Lead Screws Found In Compact Metal Lathes, And How Do They Affect The Lathe’S Functionality?Lead screws in compact metal lathes are usually about ½ inch to 1 inch in diameter. They can be a few feet long, depending on the lathe size. These screws help move the cutting tool accurately. If they are too short or thin, the lathe might not work well. Good lead screws make the lathe easier and more precise to use.

What Are The Differences Between A Standard Lead Screw And A Ball Screw In Compact Metal Lathes, And When Might One Be Preferred Over The Other?A standard lead screw moves by sliding, while a ball screw uses ball bearings to roll. This makes ball screws smoother and faster. If you need to move things quickly, use a ball screw. If you want something simple and cheaper, a standard lead screw is good.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Lead Screw In A Compact Metal Lathe, And How Does It Impact Machining Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw is a long, threaded rod in a metal lathe. It helps move the cutting tool smoothly. This movement allows us to make very precise cuts. When the lead screw works well, our finished pieces fit perfectly. That’s how it makes our work better!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Lead Screws In Compact Metal Lathes, And What Are Their Advantages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for making lead screws in compact metal lathes are steel, brass, and plastic. Steel is strong and lasts a long time. Brass is smooth and helps reduce friction. Plastic is lighter and can be cheaper, but it may not be as strong. Each material has good points that help in different tasks.”}},{“@type”: “Question”,”name”: “How Can The Lead Screw Be Maintained Or Adjusted To Ensure Smooth Operation On A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lead screw working well on a metal lathe, you should clean it often. Use a soft cloth to wipe away dirt and old oil. Next, check if it needs more oil. You can add a little machine oil to help it run smoothly. If it feels loose, you can tighten the screws to make it snug again.”}},{“@type”: “Question”,”name”: “What Are The Typical Dimensions And Specifications Of Lead Screws Found In Compact Metal Lathes, And How Do They Affect The Lathe’S Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws in compact metal lathes are usually about ½ inch to 1 inch in diameter. They can be a few feet long, depending on the lathe size. These screws help move the cutting tool accurately. If they are too short or thin, the lathe might not work well. Good lead screws make the lathe easier and more precise to use.”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Standard Lead Screw And A Ball Screw In Compact Metal Lathes, And When Might One Be Preferred Over The Other? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A standard lead screw moves by sliding, while a ball screw uses ball bearings to roll. This makes ball screws smoother and faster. If you need to move things quickly, use a ball screw. If you want something simple and cheaper, a standard lead screw is good.”}}]}