Have you ever watched someone create something amazing out of metal? It can be so cool! Compact metal lathe operations make this possible. These little machines spin metal and let you shape it into whatever you want. From parts for toys to tools for work, they can do it all.

Imagine turning a block of metal into something shiny and useful. Sounds like magic, right? Well, it’s all about understanding how to operate a compact metal lathe. You get to control the speed and shape with just a few knobs. It’s like being a wizard of metal!

Did you know that many people use compact metal lathes at home? They are not just for big factories. Hobbyists love them too! With some practice, anyone can learn. The results can be truly satisfying. Knowing how to operate a compact metal lathe can make you feel proud of what you create.

This article will guide you through the exciting world of compact metal lathe operations. You’ll discover tips, tricks, and techniques to get you started. Are you ready to unleash your creativity with metal? Let’s dive in!

Compact Metal Lathe Operations: Tips And Techniques Explained

Compact Metal Lathe Operations

Compact metal lathe operations are fascinating! These machines help shape metal into useful parts. With just a few simple tools, anyone can create items like knobs or gears. Imagine making your own unique toys or tools! Understanding how to set up and operate a lathe can feel like magic. Plus, lathe work teaches important skills. You’ll learn about precision and creativity. Did you know that even small projects can lead to big inventions? Start exploring, and who knows what you might create!Understanding the Basics of Compact Metal Lathes

Definition and purpose of a compact metal lathe. Key components and their functions.A compact metal lathe is a handy machine used mainly for shaping metal parts. Think of it as a magical stick that can turn raw metal into cool shapes! The main parts include the bed, which supports everything; the headstock, where the motor lives; and the tailstock, it holds tools steady. These components work together like a well-rehearsed dance troupe, turning metal into masterpieces. Don’t forget, safety first! No one wants to turn into a metal pancake!

| Component | Function |

|---|---|

| Bed | Supports the lathe parts and keeps everything level. |

| Headstock | Holds the motor and drive components. |

| Tailstock | Holds tools and helps with precision work. |

Essential Safety Precautions

Personal protective equipment for lathe operations. Safe operating procedures to follow.Using a lathe can be as fun as riding a roller coaster if you remember your safety gear! Always wear protective goggles to shield your eyes from flying metal shavings. Don’t forget gloves and a snug-fitting apron; you want to stay safe, not get caught in the machine! Check your work area for clutter too. It’s hard to focus on your project with a runaway coffee cup in the way. Follow these steps for safe lathe operations:

| Safety Gear | Purpose |

|---|---|

| Goggles | Protect eyes from debris |

| Gloves | Prevent hand injuries |

| Apron | Keep clothing safe |

Following these procedures can save you from some hairy situations. Remember, safety first, then craft your masterpiece!

Setting Up Your Compact Metal Lathe

Stepbystep setup process. Importance of leveling and securing the lathe.First, choose a flat surface for your compact metal lathe. This helps it work well. Next, use a level tool. Check if it’s even. If not, adjust the feet. Then, securely fasten the lathe to the table. This prevents it from moving. Following these steps makes operating smoother and safer.

- Find a sturdy, flat surface.

- Use a level to check for evenness.

- Adjust the feet if needed.

- Securely fasten the lathe to the surface.

Why is leveling important?

Leveling keeps the lathe stable. A stable lathe reduces mistakes when you cut or shape metal. It helps create accurate pieces.

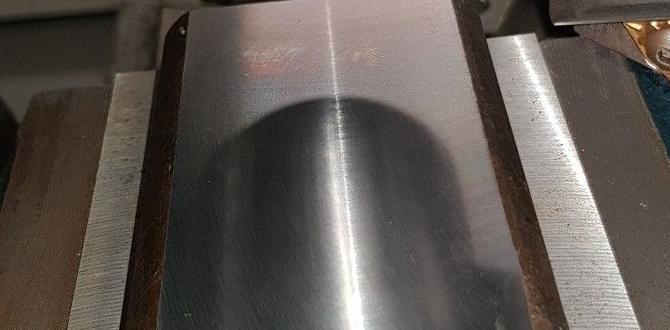

Basic Lathe Operations

Turning: techniques and procedures. Facing: definition and execution methods.Lathe operations are like a dance for metal! First up is turning. It means shaping a piece of metal while it spins. You need to choose the right tool and speed for the job. It’s like picking a dance partner who won’t step on your toes!

Next is facing, which is where you smooth the end of the metal. Imagine cutting a cake so that it’s flat and tidy. Execute this step with care to achieve a perfect finish. Using both turning and facing together makes your work shine.

| Operation | Definition | Execution |

|---|---|---|

| Turning | Shaping metal as it spins | Use the right tool and speed |

| Facing | Smoothing the end of the metal | Cut carefully for a flat finish |

These basic techniques can make all the difference. Your lathe dance will impress everyone, so grab your tool, and let’s get spinning!

Advanced Techniques in Lathe Operations

Threading: types and processes. Taper turning: tools and methods.Using advanced techniques can make lathe operations much easier and more efficient. Two key methods are threading and taper turning. With threading, you can create screws and bolts. There are different types like external and internal threading, each with specific processes. Taper turning lets you shape materials at an angle. You can use special tools like a taper attachment or a simple method with a tailstock. These techniques help in making precise and complex shapes.

What are the types of threading?

There are two main types of threading: external and internal. External threading creates the outside of a screw, while internal threading forms the inside of a hole for a screw.

What is taper turning?

Taper turning shapes materials at angles for various projects. It can be done with tools or by adjusting the machine itself.

- Use a taper attachment for better precision.

- Or use the tailstock method for simple cuts.

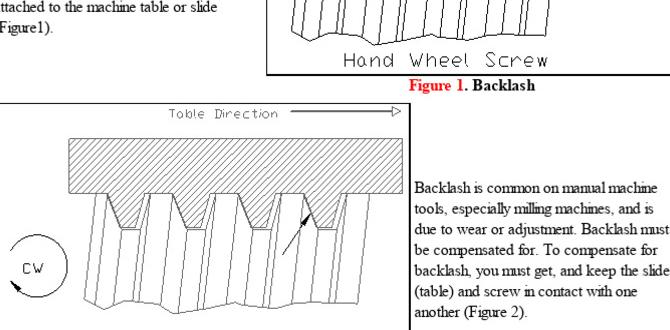

Common Problems and Troubleshooting

Identifying common issues during operations. Solutions and preventive measures.Working with a compact metal lathe can be fun, but sometimes you might run into hiccups. Issues like incorrect speeds or tool vibrations can happen. These problems can mess up your work. The good news? Most of them have easy fixes! For example, if you hear weird noises, check if your tools are tight. Keeping everything clean and well-lubricated helps prevent issues too. Below is a handy table to help you spot and solve common problems:

| Problem | Solution |

|---|---|

| Tool vibration | Tighten your tools |

| Incorrect speed | Adjust the settings |

| Dirty components | Clean and lubricate |

Remember, a tidy lathe is a happy lathe! And a happy lathe keeps you smiling, too.

Maintenance of Compact Metal Lathes

Routine maintenance tasks for longevity. Lubrication and care for optimal performance.Keeping your compact metal lathe in great shape is important for smooth operations. Regular checks can make it last longer. Routine maintenance tasks include cleaning, tightening loose parts, and checking for wear. Lubrication is vital, too. It helps moving parts work well together. Apply oil on gears and slides often. This keeps everything running nicely. Remember, a little care goes a long way!

- Clean the lathe after every use.

- Tighten loose screws and parts.

- Apply lubrication regularly.

- Inspect for damage and wear.

What is the best way to maintain a compact metal lathe?

Regular cleaning, lubrication, and inspections are the best ways to maintain a compact metal lathe. These tasks help it perform better and last longer.

Applications of Compact Metal Lathes

Industries that benefit from compact lathes. Personal projects and hobbies involving lathe work.Many industries find compact metal lathes very useful. These machines help with precise shaping of metal parts. They are common in:

- Manufacturing

- Aerospace

- Automotive

- Electronics

Hobbyists also enjoy using compact lathes for personal projects. They can create models, tools, and custom parts. This creativity makes metal lathes fun and valuable for learning. Whether in a factory or a workshop, compact metal lathes bring ideas to life.

Who uses compact metal lathes?

Industries and hobbyists alike rely on compact metal lathes for precise metal work. From making airplane parts to crafting home projects, they support a variety of tasks.

Comparing Compact Metal Lathes on the Market

Key features to consider when purchasing. Toprated compact metal lathe models and their reviews.Buying a compact metal lathe? Consider these key features:

- Size: Will it fit your workspace?

- Speed: How fast can it turn the metal?

- Power: Does it have enough strength for your projects?

- Durability: Can it last through heavy use?

- Ease of use: Is it simple for beginners?

Top-rated models include:

- Harrison M300: Great for small spaces and easy to operate.

- Sherline 4400: Ideal for beginners with solid reviews.

- Grizzly G8688: Known for its power and reliability.

Reading reviews helps you see what users like and dislike. This way, you can make a smart choice!

What should I look for in a compact metal lathe?

Look for size, speed, and ease of use. These features will help you get the best fit for your projects.

Resources for Further Learning

Recommended books and online courses. Community forums and workshops for lathe enthusiasts.Learning about compact metal lathe operations is an exciting journey! There are many great books and online courses to help you. Joining community forums is a fantastic way to meet others who share your passion. You can ask questions and share your experiences. Workshops are also available for hands-on practice. Below are some resources you can explore:

| Resource Type | Name |

|---|---|

| Book | The Essential Guide to Metal Lathes |

| Course | Intro to Lathe Operations Online |

| Forum | Lathe Lovers Community |

| Workshop | Weekend Lathe Masterclass |

With these resources, you’ll turn learning into a thrilling adventure! Remember, every expert was once a beginner, possibly causing chaos with a lathe. But hey, that’s how we learn, right?

Conclusion

In summary, compact metal lathe operations let you create precise parts efficiently. You gain control over your work and can make various items. By understanding the tools and techniques, you enhance your skills. Start practicing with small projects to build confidence. Remember, learning more about lathe operations will improve your abilities. Explore resources and keep experimenting to grow!FAQs

What Are The Essential Components Of A Compact Metal Lathe, And How Do They Function During Operation?A compact metal lathe has several key parts. First, there’s the bed, which is the strong base that holds everything together. Next, we have the headstock, where the motor spins the metal piece. The tailstock holds the other end of the metal. Finally, the tool rest lets you change tools to shape the metal as it spins. Each part works together to help you make different shapes and sizes with metal!

How Do You Properly Set Up A Compact Metal Lathe For Turning Operations To Ensure Accuracy And Safety?To set up a compact metal lathe, first, make sure it’s on a stable surface. Check that all parts are tight and secure. Adjust the tool so it sits right in the middle of the workpiece. Always wear safety glasses and keep your hands away from moving parts. Finally, test it on a scrap piece to make sure everything works well before starting your real project.

What Are The Common Materials That Can Be Machined Using A Compact Metal Lathe, And What Are The Best Practices For Each?You can use a compact metal lathe to work with materials like aluminum, brass, and steel. For aluminum, keep your tools sharp and use light cuts. Brass is softer, so it’s easier to machine; just be careful with heat. When you work with steel, go slow and use cutting oil to keep everything cool. Always wear safety gear like goggles to protect your eyes!

How Do You Troubleshoot And Resolve Common Issues That May Arise During Compact Metal Lathe Operations?To fix problems with a compact metal lathe, first, check the setup. Make sure everything is tight and in place. If you hear strange sounds, stop immediately and look for loose parts. If the cuts are not smooth, try adjusting the speed or the tool. Always wear safety gear and stay focused while you work.

What Techniques Can Be Employed To Improve Surface Finish And Dimensional Accuracy When Using A Compact Metal Lathe?To make a smooth surface and keep dimensions accurate on a metal lathe, you can try a few things. First, use sharp cutting tools to get clean cuts. Second, keep the lathe clean from dust and metal shavings. Third, adjust the speed of the lathe to match the material you are using. Lastly, take lighter cuts instead of going too deep all at once. These steps will help you create better pieces!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Compact Metal Lathe, And How Do They Function During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact metal lathe has several key parts. First, there’s the bed, which is the strong base that holds everything together. Next, we have the headstock, where the motor spins the metal piece. The tailstock holds the other end of the metal. Finally, the tool rest lets you change tools to shape the metal as it spins. Each part works together to help you make different shapes and sizes with metal!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Compact Metal Lathe For Turning Operations To Ensure Accuracy And Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a compact metal lathe, first, make sure it’s on a stable surface. Check that all parts are tight and secure. Adjust the tool so it sits right in the middle of the workpiece. Always wear safety glasses and keep your hands away from moving parts. Finally, test it on a scrap piece to make sure everything works well before starting your real project.”}},{“@type”: “Question”,”name”: “What Are The Common Materials That Can Be Machined Using A Compact Metal Lathe, And What Are The Best Practices For Each? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a compact metal lathe to work with materials like aluminum, brass, and steel. For aluminum, keep your tools sharp and use light cuts. Brass is softer, so it’s easier to machine; just be careful with heat. When you work with steel, go slow and use cutting oil to keep everything cool. Always wear safety gear like goggles to protect your eyes!”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot And Resolve Common Issues That May Arise During Compact Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a compact metal lathe, first, check the setup. Make sure everything is tight and in place. If you hear strange sounds, stop immediately and look for loose parts. If the cuts are not smooth, try adjusting the speed or the tool. Always wear safety gear and stay focused while you work.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Improve Surface Finish And Dimensional Accuracy When Using A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a smooth surface and keep dimensions accurate on a metal lathe, you can try a few things. First, use sharp cutting tools to get clean cuts. Second, keep the lathe clean from dust and metal shavings. Third, adjust the speed of the lathe to match the material you are using. Lastly, take lighter cuts instead of going too deep all at once. These steps will help you create better pieces!”}}]}