Have you ever wondered how small metal parts are made? Imagine a tiny car part or a piece of jewelry. They often start with a machine called a metal lathe. A compact metal lathe is like a magical tool that shapes metal into exact sizes and shapes.

In this article, we will dive into the world of compact metal lathe parts. What makes them special? Each part plays a vital role in how the lathe works. From the motor to the tool holder, every piece matters.

Did you know that some metal lathes are small enough to fit on a desk? They are perfect for hobbyists and inventors. It’s amazing how these machines can help create everything from cool gadgets to practical tools.

Let’s explore the exciting parts of these lathes! You might find out how they can help you turn your ideas into reality.

Understanding Compact Metal Lathe Parts For Precision Work

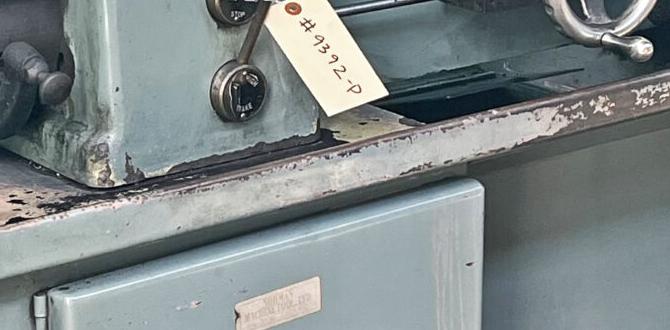

Compact Metal Lathe Parts

Compact metal lathe parts are essential for precision machining. These parts help shape and cut metal with great accuracy. Have you ever wondered how a small device can make such detailed designs? Every part plays a key role in the lathe’s function. You’ll discover how tools like the spindle, tailstock, and carriage work together. Knowing these components can improve your understanding of woodworking or metalworking projects. So, what’s your next creation?What is a Compact Metal Lathe?

Definition and importance in machining. Differences between compact and fullsized lathes.A compact metal lathe is a smaller version of traditional lathes used in machining. These lathes can spin and shape metal into parts, much like a magician pulling a rabbit from a hat! They are essential for crafting precise components in workshops. Compared to full-sized lathes, compact lathes require less space and are usually easier to operate. However, while they are nimble, they might not handle larger projects as well, which is like trying to fit an elephant in a small car!

| Feature | Compact Lathe | Full-Sized Lathe |

|---|---|---|

| Size | Small and portable | Large and heavy |

| Cost | Generally cheaper | More expensive |

| Usage | Perfect for small projects | Better for big tasks |

How to Choose the Right Compact Metal Lathe Parts

Key factors to consider (size, material, compatibility). Importance of quality and precision in parts selection.Choosing compact metal lathe parts can feel like picking the perfect ice cream flavor—there are many options, and you want the best! First, consider the size, as parts must fit your lathe. Next, look at the material; higher quality materials last longer and perform better. Lastly, ensure compatibility with your machine. Remember, quality and precision matter! Choosing the right parts can make your lathe work like a dream and save money in the long run.

| Factor | Description |

|---|---|

| Size | Must match your lathe dimensions. |

| Material | Stronger materials offer better durability. |

| Compatibility | Ensure parts fit your specific lathe model. |

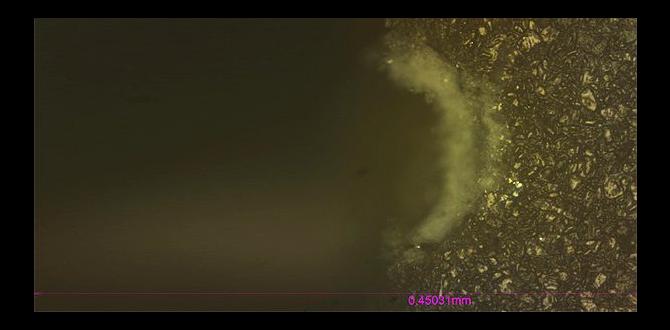

Common Compact Metal Lathe Parts and Their Functions

Detailed explanation of individual parts: spindle, chuck, gears. Functionality and impact on machining processes.When diving into the world of compact metal lathes, three parts shine the brightest: the spindle, chuck, and gears. The spindle is the heart, spinning the workpiece like a dance partner at a wedding. It keeps everything in motion! The chuck grips the material tightly, ensuring it doesn’t pull a disappearing act. Meanwhile, the gears work behind the scenes, adjusting speed and power. Together, they create precision in machining. Sometimes they feel like a team of superheroes, each with a special power!

| Part | Function |

|---|---|

| Spindle | Holds and spins the workpiece |

| Chuck | Grips the material securely |

| Gears | Adjusts speed and power |

Maintaining Your Compact Metal Lathe Parts

Best practices for maintenance and care. Common issues and troubleshooting tips.Taking care of your compact metal lathe parts is like giving your puppy a bath—it keeps everything clean and happy! To maintain them, remember to regularly clean the surfaces and oil the moving parts. This helps avoid rust and keeps things running smoothly! Got a problem? Check for loose screws or unusual noises; they might just need a bit of TLC. Here’s a handy table to remind you of the best practices:

| Practice | Tip |

|---|---|

| Cleaning | Wipe down after each use. |

| Lubrication | Use oil on moving parts. |

| Tightening | Check for loose screws monthly. |

Following these steps can prevent most common issues, making your lathe a happy tool! Remember, a well-maintained lathe is like a happy dance—it works like a dream!

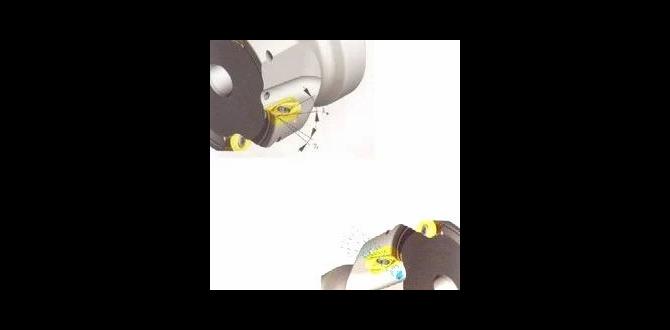

Upgrading Compact Metal Lathe Parts for Enhanced Performance

Options for aftermarket parts and enhancements. How upgrades can improve precision and efficiency.Upgrading your compact metal lathe parts can feel like giving your machine a superpower boost! Aftermarket parts, like better cutting tools or high-quality bearings, can make a world of difference. With these enhancements, you’ll enjoy sharper precision, cutting down on mistakes. Imagine turning a block of metal so smoothly that it practically dances on your lathe! Plus, higher efficiency means you can get more work done in less time. Who knew metalworking could be this fun?

| Part | Benefit |

|---|---|

| High-Quality Cutting Tools | Improved Precision |

| Heavy-Duty Bearings | Increased Efficiency |

| Upgraded Motors | Faster Operation |

So, if you want your lathe to shine like a star at a talent show, think about these upgrades! You’ll turn out better work and have a blast while doing it.

Where to Buy Compact Metal Lathe Parts

Recommended suppliers and manufacturers. Factors to consider when purchasing parts online.Finding the right place to buy compact metal lathe parts can be easy. Look for suppliers with good reputations and positive reviews. Some recommended places include local hardware stores and online retailers like Amazon. Be sure to check if they offer warranties.

Before buying, consider these factors:

- Quality: Are the parts sturdy and reliable?

- Price: Does it fit your budget?

- Shipping: How fast can you get the parts?

- Return Policy: Can you return parts if they don’t fit?

What should I know before buying compact metal lathe parts online?

Before buying, always check reviews and compare prices. Make sure the parts you want will work for your lathe. This can save you time and money.

Safety Considerations When Using Compact Metal Lathes

Essential safety gear and precautions. Best practices for safe operation of lathe parts.Using a compact metal lathe can be a blast, but safety should always come first. It’s smart to wear essential safety gear like goggles, gloves, and ear protection. Think of them as your superhero outfit! Always check the lathe parts before you start. Loose screws or damaged pieces can turn your project into a flying object—nobody wants that!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect eyes from flying debris |

| Gloves | Avoid cuts and scrapes |

| Ear Protection | Reduce noise exposure |

Always follow best practices. Keep your work area tidy, and ensure the lathe is fully stopped before reaching for those tempting metal shavings. Remember, safety isn’t boring; it’s smart and keeps your fingers intact!

Conclusion

In summary, compact metal lathe parts are essential for creating precise and durable machines. They help you make accurate shapes and sizes in metalwork. If you plan to work with metal lathes, consider learning more about these parts. Explore different types to find what fits your projects best. Remember, the right parts lead to better results! Happy machining!FAQs

What Are The Essential Components Of A Compact Metal Lathe That Contribute To Its Overall Functionality?A compact metal lathe has several important parts. First, there’s the bed, which holds everything in place. Next, we have the motor that spins the metal. The tool rest helps hold the cutting tools steady. Lastly, the controls let you adjust the speed and direction of the cutting. Together, these parts make the lathe work well.

How Do Different Materials Used In The Construction Of Compact Metal Lathe Parts Affect Their Durability And Performance?Different materials make metal lathe parts strong or weak. For example, steel is tough and lasts a long time. Aluminum is lighter but can wear out faster. If you use better materials, your lathe will work better and last longer, helping you make great things!

What Maintenance Practices Should Be Implemented To Ensure The Longevity Of Parts In A Compact Metal Lathe?To keep your compact metal lathe working well for a long time, you should clean it regularly. Wipe off dust and metal shavings after each use. You also need to oil moving parts to keep them from rusting and grinding. Check for any loose screws or parts and tighten them if needed. Finally, store the lathe in a dry place to prevent damage.

How Does The Design Of The Bed And Tailstock Impact The Accuracy And Stability Of A Compact Metal Lathe?The bed of a compact metal lathe holds everything in place. If it’s straight and strong, the machine stays stable. The tailstock helps with extra support when you cut metal. A good design makes sure everything lines up, helping you create accurate shapes. This keeps your work looking neat and clean!

What Aftermarket Accessories Or Upgrades Are Commonly Available For Enhancing The Capabilities Of A Compact Metal Lathe?You can add cool upgrades to a compact metal lathe to make it better. Some common ones are quicker tools for changing parts, new cutting tools, and special stands for better support. You can also get improved measuring tools to help you make precise cuts. These accessories help you work faster and create better projects.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Compact Metal Lathe That Contribute To Its Overall Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact metal lathe has several important parts. First, there’s the bed, which holds everything in place. Next, we have the motor that spins the metal. The tool rest helps hold the cutting tools steady. Lastly, the controls let you adjust the speed and direction of the cutting. Together, these parts make the lathe work well.”}},{“@type”: “Question”,”name”: “How Do Different Materials Used In The Construction Of Compact Metal Lathe Parts Affect Their Durability And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials make metal lathe parts strong or weak. For example, steel is tough and lasts a long time. Aluminum is lighter but can wear out faster. If you use better materials, your lathe will work better and last longer, helping you make great things!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure The Longevity Of Parts In A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your compact metal lathe working well for a long time, you should clean it regularly. Wipe off dust and metal shavings after each use. You also need to oil moving parts to keep them from rusting and grinding. Check for any loose screws or parts and tighten them if needed. Finally, store the lathe in a dry place to prevent damage.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Bed And Tailstock Impact The Accuracy And Stability Of A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The bed of a compact metal lathe holds everything in place. If it’s straight and strong, the machine stays stable. The tailstock helps with extra support when you cut metal. A good design makes sure everything lines up, helping you create accurate shapes. This keeps your work looking neat and clean!”}},{“@type”: “Question”,”name”: “What Aftermarket Accessories Or Upgrades Are Commonly Available For Enhancing The Capabilities Of A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add cool upgrades to a compact metal lathe to make it better. Some common ones are quicker tools for changing parts, new cutting tools, and special stands for better support. You can also get improved measuring tools to help you make precise cuts. These accessories help you work faster and create better projects.”}}]}