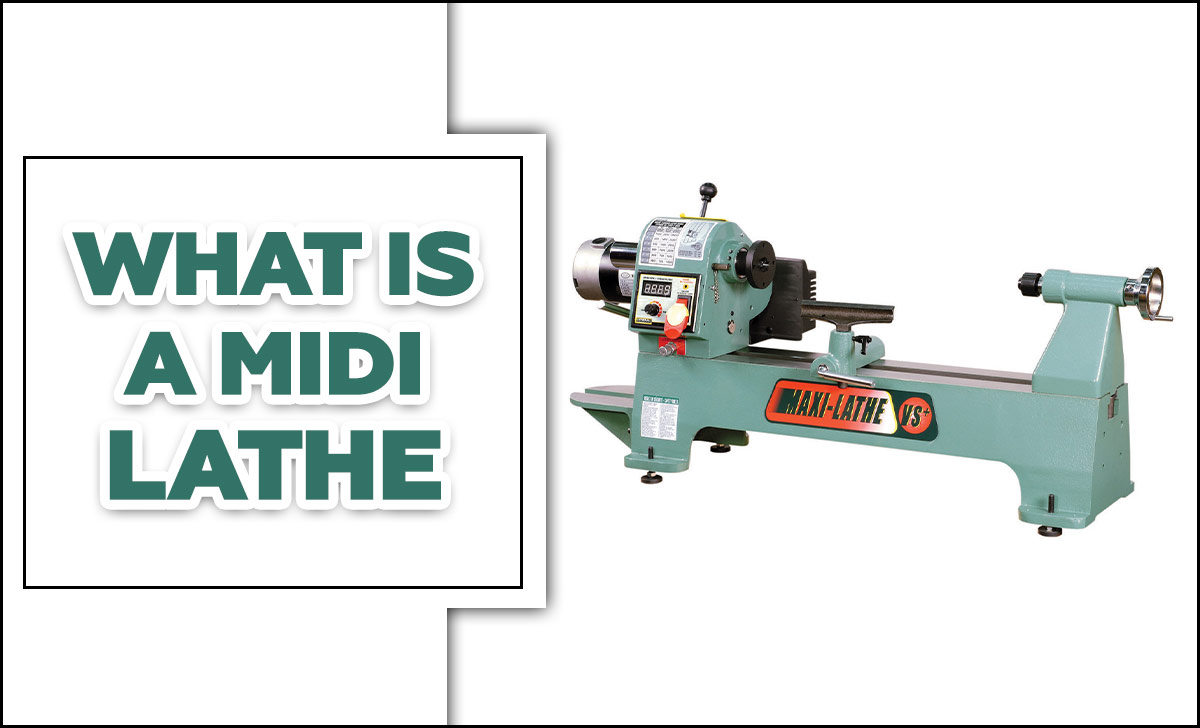

Have you ever wondered how a small machine can create precise parts? A compact metal lathe saddle makes this possible. This special part holds the lathe’s tool in place. It helps shape metal into exactly what you need. Imagine building something amazing with it!

Many people think lathes are only for big shops, but that’s not true. Compact lathes fit in smaller spaces. They are perfect for home projects or schools. Have you seen how much fun it is to create with tools like these?

Here’s a fun fact: Lathes have been around for thousands of years! They started as simple wooden designs. Now, they are advanced machines that help engineers, artists, and hobbyists. With a compact metal lathe saddle, anyone can make their ideas come to life.

Join us as we explore more about compact metal lathes. You might find yourself inspired to start your own project!

Compact Metal Lathe Saddle: Key Features And Benefits

Understanding the Compact Metal Lathe Saddle

The compact metal lathe saddle is a crucial part of small lathes. It holds the cutting tool in place as the workpiece rotates. This allows for precise shaping and machining of metal. Many hobbyists and professionals choose compact lathes for their efficiency and versatility. Did you know that using a compact lathe can save space in your workshop? With easy operation, these tools can produce detailed work, making them popular among makers everywhere.Understanding Compact Metal Lathe Components

Definition and significance of a lathe saddle. Key components and their functions.A lathe saddle is an important part of a compact metal lathe. It holds the cutting tools and helps them move smoothly. This allows for precise shaping of materials like metal and wood. Understanding its key components makes using a lathe easier.

- Saddle Base: Supports the entire saddle and helps it move left and right.

- Cross Slide: Allows vertical movement for precise cuts.

- Tool Post: Holds the cutting tool in place securely.

- Handwheels: Controls the movement of the saddle.

Each part is important for getting smooth, perfect results. A well-functioning saddle leads to better projects.

What is the function of a lathe saddle?

The lathe saddle holds tools in place and guides them during cuts. This helps create detailed shapes in materials safely.

Why is the saddle important?

- Ensures accuracy in cuts.

- Improves consistency in projects.

- Makes the lathe easier to use.

When all parts work together, anyone can make amazing things with a compact metal lathe!

Benefits of Using a Compact Metal Lathe Saddle

Advantages of a compact design in machining. Enhanced precision and control offered by the saddle.Using a small metal lathe saddle can make machining easier and more precise. Its compact design allows you to work in tight spaces. This means less clutter and easier access to your projects. The saddle gives you better control over your cuts. You can create detailed shapes and avoid mistakes. Here are some key benefits:

- Space Saving: Fits well in small workshops.

- Better Precision: Helps you cut with accuracy.

- Improved Control: Makes handling easier during projects.

Overall, a compact metal lathe saddle can boost your creative work and efficiency.

What are the advantages of a compact metal lathe saddle?

A compact metal lathe saddle offers better control, precision, and efficiency compared to larger models. It helps machinists produce high-quality work even in smaller spaces.

Choosing the Right Compact Metal Lathe Saddle

Factors to consider when selecting a saddle. Recommended brands and models in the market.Choosing a saddle for your compact metal lathe is like picking the perfect ice cream flavor—there’s a lot to consider! First, think about size. It needs to fit your lathe and work with your projects. Next, check the material; a strong and durable saddle is key, especially if you’re spinning steel instead of just whipping up smoothies. Popular brands like Grizzly and Jet make great models you can trust. Here’s a quick look:

| Brand | Model | Features |

|---|---|---|

| Grizzly | G0602 | Heavy-duty, versatile |

| Jet | JWL-1442 | Wide range of features, user-friendly |

Remember, the right saddle will make your lathe friendlier than a puppy! Happy crafting!

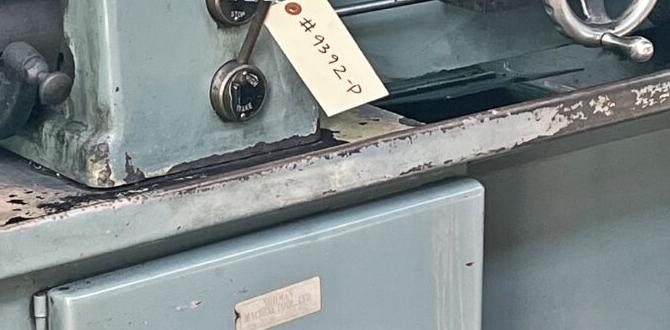

Maintenance and Care for Lathe Saddles

Best practices for maintaining saddle performance. Common issues and troubleshooting tips.To keep your lathe saddle running smoothly, regular checks are important. Dust and chips are like pesky gremlins; they can cause issues. Clean the saddle often. Use a soft brush or compressed air to wipe away debris. Also, oil the moving parts to keep things slick. By doing this, you reduce wear and tear, boosting performance.

Common problems are usually easy to spot. If the saddle feels stiff, it may need oil or cleaning. Sometimes, alignment issues pop up, causing uneven cuts. Tightening screws can often fix this. Don’t stress! A little maintenance goes a long way. Here’s a quick guide:

| Issue | Solution |

|---|---|

| Stiff movement | Apply oil and clean |

| Uneven cuts | Tighten alignment screws |

| Excess noise | Check for loose parts |

Remember, a well-cared saddle is a happy saddle! Keep an eye on it and you’ll enjoy a smooth ride.

Applications of Compact Metal Lathes in Industry

Typical industries that utilize compact lathes. Examples of projects suited for compact lathes.Many industries use compact metal lathes. They are popular in manufacturing and maintenance shops. These machines create small parts with great precision. They can make items like bolts, gears, and tools. Compact lathes are great for tasks that need fine details and smooth finishes.

- Aerospace

- Automotive

- Electronics

Projects for compact lathes include:

- Custom parts for machines

- Repairing broken items

- Creating prototypes for new inventions

What are some common uses of compact metal lathes?

Compact metal lathes are used for making precision parts and prototypes in various industries, including aerospace, automotive, and electronics.

Comparative Analysis with Traditional Lathes

Key differences between compact metal lathes and traditional lathes. Pros and cons of each type.Compact metal lathes and traditional lathes are like apples and oranges, both useful but different! Compact lathes save space and are perfect for small projects, while traditional lathes are big and tough, ideal for heavy-duty work. However, compact lathes often lack power for larger tasks. On the bright side, they are easier to use and transport. Let’s look at their key differences:

| Feature | Compact Metal Lathe | Traditional Lathe |

|---|---|---|

| Size | Small and handy | Large and heavy |

| Power | Less power | More powerful |

| Ease of Use | Beginner-friendly | May require more skill |

| Portability | Easy to move | Not so portable |

In short, choose a compact lathe if you’re new or short on space. Opt for a traditional lathe if you need power and have room to spare. Remember, it’s not the size of the lathe in the fight, but the skill of the maker!

Future Trends in Compact Metal Lathe Technology

Emerging technologies influencing lathe design. Predictions for the future of compact metal lathes.Exciting changes are happening with compact metal lathe technology! New tools are coming out, making lathes easier to use and more efficient. Smart sensors and automation are sneaking into design, helping lathe operators create perfect parts every time. Some predict that in the near future, lathe machines will even talk to each other! Imagine your lathe asking you for coffee breaks. It’s not just a dream. These advancements promise a fun mix of precision and tech!

| Technology | Description |

|---|---|

| Smart Sensors | Help monitor performance and adjust settings automatically. |

| Automation | Makes repetitive tasks easier, so less human effort is needed. |

| AI Integration | Could lead to more intelligent machining processes in the future. |

Conclusion

In summary, a compact metal lathe saddle is essential for machine stability and precision. It allows you to create accurate shapes and parts. Understanding its features helps you choose the right lathe for your projects. We encourage you to explore more about lathe components and their roles. Start experimenting with your skills to create amazing metalworks!FAQs

Sure! Here Are Five Questions Related To The Topic Of A Compact Metal Lathe Saddle:Sure! Here are five questions about a compact metal lathe saddle: 1. **What does a metal lathe saddle do?** A metal lathe saddle holds the part you are shaping. It moves back and forth to help you work on it. 2. **Why is the saddle important?** The saddle helps keep everything steady. This makes it easier to create precise shapes. 3. **How do you adjust the saddle?** You can adjust the saddle with a lever or a knob. This lets you move it closer or farther away. 4. **Can anyone use a lathe saddle?** Yes! Anyone can learn to use it with practice. Just be safe and ask for help if needed. 5. **Where can you see a metal lathe saddle?** You can find it in workshops or schools. It’s often used in classes about making things from metal.

Sure! Please share the question you would like me to answer.

What Is The Primary Function Of The Saddle In A Compact Metal Lathe?The saddle in a compact metal lathe helps to hold the cutting tool. It moves side to side to shape metal pieces. You can slide it back and forth to cut different shapes. This makes it easier for you to work on metal parts.

How Does The Design Of The Saddle Influence The Overall Accuracy Of Machining Operations?The saddle is a part of a machine that holds things in place while we work on them. A well-designed saddle keeps everything steady and in the right spot. If the saddle is strong and fits well, it helps the machine make accurate cuts and shapes. When the saddle doesn’t work well, it can cause mistakes in the work we do. So, a good saddle design helps us do a better job!

What Materials Are Commonly Used In The Construction Of A Lathe Saddle, And Why Are They Chosen?Lathe saddles are often made from metal, usually cast iron or steel. These materials are strong and heavy, which helps keep the lathe steady. We choose them because they can handle a lot of work without breaking. They’re also good at reducing vibrations, which helps make sharper and cleaner cuts.

How Can Wear And Tear On The Saddle Affect The Performance Of A Compact Metal Lathe?When the saddle on a compact metal lathe wears out, it can cause problems. The saddle helps the tool move smoothly. If it’s damaged, the tool may shake or skip while working. This can make your pieces messy or not the right size. Keeping the saddle in good shape is important for clean and precise work.

What Maintenance Practices Are Recommended To Prolong The Life Of A Lathe Saddle?To keep your lathe saddle in good shape, clean it often. Use a soft cloth to wipe away dust and oil. Check for any worn parts and replace them if needed. Lubricate the moving parts regularly to prevent rust. Lastly, keep the lathe in a dry place to protect it from moisture.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of A Compact Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about a compact metal lathe saddle: 1. **What does a metal lathe saddle do?** A metal lathe saddle holds the part you are shaping. It moves back and forth to help you work on it. 2. **Why is the saddle important?** The saddle helps keep everything steady. This makes it easier to create precise shapes. 3. **How do you adjust the saddle?** You can adjust the saddle with a lever or a knob. This lets you move it closer or farther away. 4. **Can anyone use a lathe saddle?** Yes! Anyone can learn to use it with practice. Just be safe and ask for help if needed. 5. **Where can you see a metal lathe saddle?** You can find it in workshops or schools. It’s often used in classes about making things from metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Saddle In A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle in a compact metal lathe helps to hold the cutting tool. It moves side to side to shape metal pieces. You can slide it back and forth to cut different shapes. This makes it easier for you to work on metal parts.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Saddle Influence The Overall Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle is a part of a machine that holds things in place while we work on them. A well-designed saddle keeps everything steady and in the right spot. If the saddle is strong and fits well, it helps the machine make accurate cuts and shapes. When the saddle doesn’t work well, it can cause mistakes in the work we do. So, a good saddle design helps us do a better job!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of A Lathe Saddle, And Why Are They Chosen?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe saddles are often made from metal, usually cast iron or steel. These materials are strong and heavy, which helps keep the lathe steady. We choose them because they can handle a lot of work without breaking. They’re also good at reducing vibrations, which helps make sharper and cleaner cuts.”}},{“@type”: “Question”,”name”: “How Can Wear And Tear On The Saddle Affect The Performance Of A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the saddle on a compact metal lathe wears out, it can cause problems. The saddle helps the tool move smoothly. If it’s damaged, the tool may shake or skip while working. This can make your pieces messy or not the right size. Keeping the saddle in good shape is important for clean and precise work.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended To Prolong The Life Of A Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe saddle in good shape, clean it often. Use a soft cloth to wipe away dust and oil. Check for any worn parts and replace them if needed. Lubricate the moving parts regularly to prevent rust. Lastly, keep the lathe in a dry place to protect it from moisture.”}}]}