Have you ever wanted to create amazing projects with metal? A compact metal lathe might be just what you need! This powerful tool can shape metal into just about anything. Setting it up correctly is key to getting the best results.

Imagine turning raw metal into beautiful parts for your projects. It feels rewarding, doesn’t it? With the right tips and a good compact metal lathe setup, you can do wonders. Did you know that a well-organized workspace can boost your creativity? It’s true!

In this article, we will explore how to set up your compact metal lathe. You’ll learn simple steps, useful tips, and some common mistakes to avoid. Get ready to dive into the exciting world of metalworking!

Compact Metal Lathe Setup: Essential Tips For Success

Compact Metal Lathe Setup

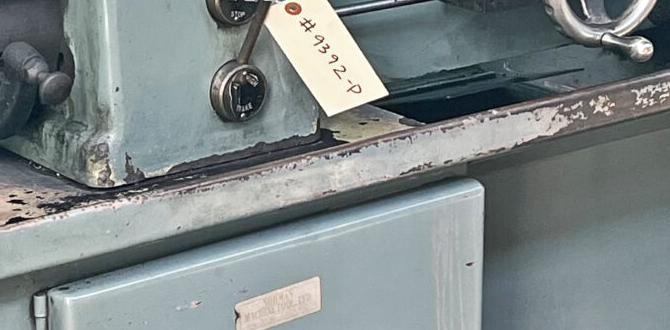

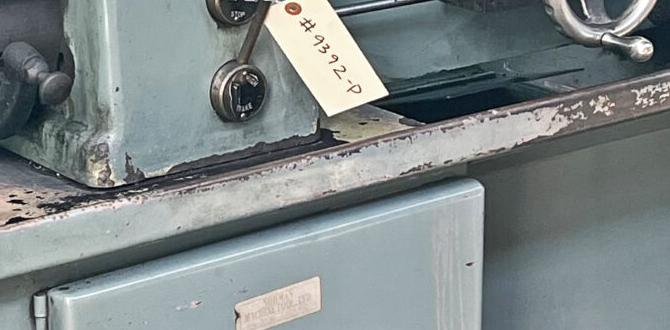

Setting up a compact metal lathe can be an exciting project. First, ensure you have a sturdy workspace. Did you know proper leveling can improve your lathe’s performance? Next, secure the lathe firmly to avoid vibrations during operation. This keeps your work precise. Use the right tools and follow safety steps to protect yourself. Whether you’re a hobbyist or a pro, a well-set lathe helps create amazing projects. Happy turning!Understanding Compact Metal Lathes

Definition and purpose of compact metal lathes. Advantages of using compact metal lathes for hobbyists and professionals.Compact metal lathes are small machines designed to shape metal. They help create parts by spinning the material and cutting it down to the desired size. Hobbyists use them for fun projects, while professionals rely on them for precise work. The best part? They fit in tight spaces, making them perfect for small workshops!

Some advantages include:

| Benefits | Description |

|---|---|

| Space-Saving | They are small and fit easily in your garage or shed. |

| Easy to Use | Perfect for beginners and seasoned pros alike! |

| Affordable | Great value for the features they offer! |

These little lathes can be a handy tool! They turn metal into art or practical parts all while saving space. Talk about multitasking!

Components of a Compact Metal Lathe

Key parts and their functions (bed, spindle, tailstock, etc.). Importance of each component in the lathe setup.A compact metal lathe has several key components that work together like teammates in a game. Each part plays a special role. Let’s break it down:

| Component | Function |

|---|---|

| Bed | Supports all parts and keeps them in place. Think of it as a sturdy table! |

| Spindle | Holds the workpiece and spins it for shaping. It’s like the dance partner of all metal! |

| Tailstock | Helps support long pieces and offers extra tools. It’s the friendly sidekick! |

Each component is essential in a compact metal lathe setup. Without them, there would be chaos, and nobody likes a messy dance floor! So, remember, without these parts, you can only pretend to be a metal wizard.

Selecting the Right Compact Metal Lathe

Factors to consider (size, power, features). Comparison of popular models in the market.Choosing a compact metal lathe can feel like picking a flavor of ice cream—so many choices and they all look good! First, think about size; make sure it fits in your workshop without turning it into a game of Tetris. Next, check the power. More power can mean more fun and less frustration while working. Features like speed settings can be handy, letting you create like a pro.

Now, let’s look at a few popular models:

| Model | Size | Power | Features |

|---|---|---|---|

| LatheMaster 2400 | 30x15x15 in | 1 HP | Variable speed, Digital display |

| MiniMachiner X200 | 28x12x12 in | 0.75 HP | Multiple tooling options |

Whether you want to make tiny gadgets or repair parts, finding the right compact lathe can help you turn your ideas into reality. So, grab your toolbox and get ready to spin some magic!

Essential Tools and Accessories for Setup

Necessary tools for assembly and operation. Recommended accessories to enhance functionality.Building your compact metal lathe is much easier with the right tools and accessories. First, you need some basics: a wrench set and screwdrivers. They help assemble everything without turning you into a frustrated puzzle master. Next, consider a high-quality cutting tool to shape metals; it’s like giving your lathe a magic wand!

Recommended accessories include a steady rest, which prevents wobbling during use. Just think of it as a seatbelt for your projects! A set of collets is great too; they hold workpieces firmly, so you won’t need to juggle metal parts like a circus performer. To help you remember, here’s a handy table:

| Essential Tools | Recommended Accessories |

|---|---|

| Wrench Set | Steady Rest |

| Screwdrivers | Set of Collets |

| Cutting Tool | Tool Holder |

With these tools and accessories, you’ll be better prepared for your metalworking adventure! Don’t worry; no capes required. Happy turning!

Preparing Your Workspace

Ideal workspace requirements for compact lathes. Safety considerations and organization tips.Having the right space for your compact lathe is very important. Choose a stable, flat surface for your lathe. Make sure it’s away from direct sunlight and dust. Good lighting helps you see clearly. Keep your tools neatly organized to avoid accidents. For safety:

- Wear safety goggles.

- Keep the area clean.

- Never work alone if possible.

These steps make your workspace safe and enjoyable for using your compact lathe.

What are essential factors for setting up a compact lathe workspace?

Key factors include stable surfaces, adequate lighting, and keeping tools organized.Remember, a well-prepared workspace helps you work better.

Step-by-Step Setup Process

Detailed steps for assembling the lathe. Tips for leveling and calibrating the machine.Assembling your lathe can feel like a puzzle, but luckily, it’s a puzzle with all the pieces included! Start by placing the main body on a sturdy table. Make sure everything is level—if not, your lathe will wobble like a puppy trying to walk! Next, secure the headstock and tailstock in place. Calibrate the machine carefully, as even small adjustments can make big differences. Don’t forget to check the alignment; it should be straight like an arrow. Remember, leveling is key to avoiding surprises while working!

| Step | Action |

|---|---|

| 1 | Set up the main body on a flat surface. |

| 2 | Attach the headstock and tailstock. |

| 3 | Level and calibrate the lathe. |

| 4 | Check alignment for best results. |

With patience and these steps, you’re on your way to mastering the world of metal lathing. Have fun, and keep that tool sharp—metaphorically speaking, of course!

Initial Testing and Adjustments

Procedures for initial test runs. Common adjustments to ensure precision and accuracy.Testing your new compact metal lathe is like making sure your shiny bike is ready for a race. First, run a simple test with a piece of scrap metal. Slowly check if it cuts smoothly. If it sounds like a crow squawking, it’s time for adjustments!

Common tweaks include balancing the tool holder and checking the feed rate. These steps help keep your projects on point, like a laser-focused squirrel. Below is a quick reference for your adjustments:

| Adjustment | Purpose |

|---|---|

| Tool Holder Balance | Ensures smooth cutting |

| Feed Rate | Maintains precision |

Remember, a little adjustment goes a long way. Happy turning!

Maintenance Tips for Longevity

Regular maintenance practices for compact lathes. Signs of wear and effective troubleshooting steps.Keeping your compact lathe happy is like nurturing a pet. Regular maintenance is key! Check the oil levels frequently to keep the gears purring. Look out for signs of wear, like unusual noises or rough movements. If something feels off, don’t ignore it! A little troubleshooting goes a long way. Here are some handy tips:

| Maintenance Tip | Action |

|---|---|

| Check Belts | Look for cracks or fraying. |

| Clean Regularly | Dust can shorten the lathe’s life. |

| Lubricate Moving Parts | Makes everything run smoother. |

Remember, a well-cared lathe can make your projects “lathe-tastic” for years. Don’t let it turn into a rusty relic!

Common Projects and Applications

Examples of projects suitable for compact lathes. Tips for selecting suitable materials for machining.Compact lathes can handle many fun projects. You can make things like small furniture parts, tools, or used for model making. They are great for turning wood or metal into shapes you want. Always pick materials that are easy to machine. Some good choices include:

- Aluminum

- Brass

- Softwood

- Plastic

With the right materials, you can create amazing things with your lathe!

What can I create with a compact metal lathe?

You can create items like custom parts, toys, and jewelry. Use your creativity!

Resources for Further Learning

Recommended books, online courses, and forums for lathe users. Community resources for sharing projects and tips. “`htmlLearning about compact metal lathe setups can be fun and rewarding! There are many resources to help you get started. For books, check out classics like “The Metal Lathe” by Tom McCready. It’s like a treasure map but for lathes! Online courses on platforms like Udemy and Coursera offer great video guides to follow along.

Don’t forget about forums like the Machinist’s Board. Here, you can share tips and ask for advice. It’s like a friendly neighborhood but for metalworkers! You can learn from others’ projects and even share your own, getting that sweet *community* feedback! Check out the table below for more useful resources:

| Type | Resource |

|---|---|

| Book | “The Metal Lathe” by Tom McCready |

| Online Course | Udemy’s Metalworking course |

| Forum | Machinist’s Board |

Conclusion

In conclusion, setting up a compact metal lathe can boost your metalworking skills. You’ll learn to create precise parts easily. Remember to choose the right tools and keep your workspace organized. Always prioritize safety. If you’re excited, consider researching more about different lathe projects. Get your hands dirty and start making something amazing today!FAQs

What Are The Key Factors To Consider When Selecting A Space For A Compact Metal Lathe Setup?When picking a space for a compact metal lathe, you need to think about a few things. First, make sure the area is strong enough to hold the lathe’s weight. You also want to have enough room around it so you can work safely. Good lighting is important, too, so you can see what you’re doing. Finally, keep the lathe away from places where kids or pets might run around.

How Can I Optimize The Layout Of My Workspace To Accommodate A Compact Metal Lathe For Efficient Operation?To make space for your metal lathe, first, clear out everything you don’t need. You want to keep tools and materials close by. Place your lathe against a sturdy wall to save space. Make sure there’s enough room to move around it easily. Finally, organize your tools in boxes or shelves for easy access.

What Essential Tools And Accessories Should I Have On Hand For A Compact Metal Lathe Setup?For a compact metal lathe setup, you need some key tools. First, get a tool holder that fits your lathe. You will also need sharp cutting tools for shaping metal. A measuring tool like a caliper helps you check sizes. Finally, don’t forget a safety guard and some cutting oil to keep everything running smoothly.

What Are The Best Practices For Maintaining A Compact Metal Lathe To Ensure Precision And Longevity?To keep your metal lathe running well, always clean it after using it. You should oil the moving parts regularly to avoid rust. Check the belts and gears for wear and replace them if they’re damaged. It’s important to keep the lathe on a stable surface so it doesn’t shake. Lastly, always follow the manufacturer’s instructions for care!

How Can I Make The Most Of A Limited Budget While Setting Up A Compact Metal Lathe System?To make the most of a limited budget for a compact metal lathe system, start by buying used tools. Check online marketplaces or local shops for good deals. Focus on getting the basics first, like the lathe and essential accessories. You can add more tools later as your budget grows. Lastly, learn online for free about using your lathe to save money on classes!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Space For A Compact Metal Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a space for a compact metal lathe, you need to think about a few things. First, make sure the area is strong enough to hold the lathe’s weight. You also want to have enough room around it so you can work safely. Good lighting is important, too, so you can see what you’re doing. Finally, keep the lathe away from places where kids or pets might run around.”}},{“@type”: “Question”,”name”: “How Can I Optimize The Layout Of My Workspace To Accommodate A Compact Metal Lathe For Efficient Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make space for your metal lathe, first, clear out everything you don’t need. You want to keep tools and materials close by. Place your lathe against a sturdy wall to save space. Make sure there’s enough room to move around it easily. Finally, organize your tools in boxes or shelves for easy access.”}},{“@type”: “Question”,”name”: “What Essential Tools And Accessories Should I Have On Hand For A Compact Metal Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a compact metal lathe setup, you need some key tools. First, get a tool holder that fits your lathe. You will also need sharp cutting tools for shaping metal. A measuring tool like a caliper helps you check sizes. Finally, don’t forget a safety guard and some cutting oil to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining A Compact Metal Lathe To Ensure Precision And Longevity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe running well, always clean it after using it. You should oil the moving parts regularly to avoid rust. Check the belts and gears for wear and replace them if they’re damaged. It’s important to keep the lathe on a stable surface so it doesn’t shake. Lastly, always follow the manufacturer’s instructions for care!”}},{“@type”: “Question”,”name”: “How Can I Make The Most Of A Limited Budget While Setting Up A Compact Metal Lathe System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the most of a limited budget for a compact metal lathe system, start by buying used tools. Check online marketplaces or local shops for good deals. Focus on getting the basics first, like the lathe and essential accessories. You can add more tools later as your budget grows. Lastly, learn online for free about using your lathe to save money on classes!”}}]}