Have you ever wondered how tiny metal parts are made? It’s a fascinating process! One of the tools that makes it possible is a compact metal lathe. This machine can do many amazing things. One of its coolest features is thread cutting.

Imagine needing to create a perfect screw or a bolt. It sounds tricky, right? But with a compact metal lathe, this task becomes easier. The machine shapes metal quickly and accurately. You can make threads that fit perfectly, just like magic!

Did you know that many things around you contain parts made with thread cutting? From bicycles to computers, compact metal lathes help create these everyday items. They play a huge role in our lives, even if we don’t realize it.

This article will explore how compact metal lathes work and why they are so important for thread cutting. Ready to dive into the world of machinery? Let’s begin!

Compact Metal Lathe Thread Cutting: A Beginner’S Guide

Understanding Compact Metal Lathe Thread Cutting

Compact metal lathe thread cutting is a valuable skill for hobbyists and professionals. It allows you to create precise threads on metal objects. Have you ever needed a custom part? A metal lathe can help! These machines are smaller but pack a punch. You can work on various projects without taking up too much space. Plus, using a lathe can boost your creativity and problem-solving skills. Isn’t it exciting to produce your own parts?Understanding Compact Metal Lathes

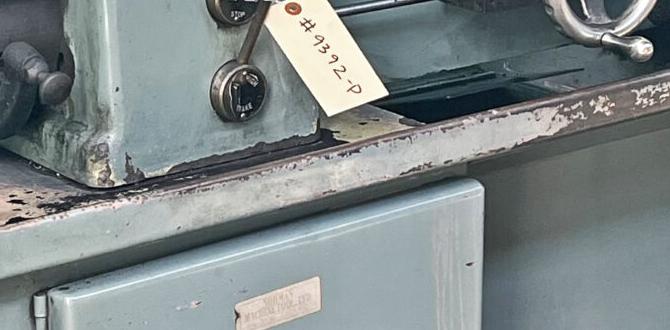

Definition and features of compact metal lathes. Comparison with traditional lathes.Compact metal lathes are small machines that spin metal to shape it into various items. They are like tiny magic wands for metal! These lathes are known for their precision and ability to create detailed designs. Compared to traditional lathes, compact versions take up less space. They are perfect for hobbyists or small workshops. Think of them as the “minis” in the lathe world—small but mighty!

| Feature | Compact Metal Lathes | Traditional Lathes |

|---|---|---|

| Size | Small and portable | Large and heavy |

| Usage | Great for small projects | Best for big jobs |

| Cost | More affordable | Usually pricier |

Importance of Thread Cutting in Metalworking

Applications of thread cutting in various industries. Benefits of proficient thread cutting skills.Thread cutting is like the secret sauce in metalworking. It makes parts fit together perfectly! Many industries rely on this skill. For example, the car industry uses it to make nuts and bolts. This ensures cars run smoothly. The aerospace sector uses thread cutting too. It keeps airplanes safe and together in the sky.

| Industry | Application |

|---|---|

| Automotive | Nuts and bolts for engines |

| Aerospace | Parts for planes and rockets |

| Construction | Support beams and frames |

Having good thread-cutting skills brings lots of benefits. It can save time and money. Plus, it helps create sturdy products. Think about it—no one wants a loose screw! Mastering this technique makes you a hot commodity in the job market. Employers love people who can thread cut like a pro!

Types of Threads and Their Applications

Common types of threads (e.g., UNC, UNF, Metric). Choosing the right thread type for specific projects.Threads play an important role in many projects. Common types include UNC (Unified National Coarse), UNF (Unified National Fine), and Metric threads. Each type serves a different purpose. Choosing the right thread is essential for success. For instance:

- UNC is strong and great for heavy loads.

- UNF fits tighter spaces but is less strong.

- Metric is standard in many countries and works with specific measurements.

Pick wisely to ensure your project works as planned!

What are the different types of threads?

UNC, UNF, and Metric are the main types of threads used in projects.Choosing the right type helps in:

- Ensuring structure

- Improving fit

- Enhancing strength

Setting Up Your Compact Metal Lathe for Thread Cutting

Essential tools and accessories needed. Stepbystep setup process.Gear up for some fun with your compact metal lathe! First, gather essential tools like cutting tools, a tailstock, and a carriage. You’ll also need measuring tools for precision. Now, let’s roll up our sleeves for the setup process!

| Essential Tools | Purpose |

|---|---|

| Cutting Tools | Shape the metal into threads. |

| Tailstock | Stabilizes the workpiece. |

| Measuring Tools | Ensure accurate threading. |

Start by securing your metal piece. Next, adjust the tool holder for height. Then, check the feed rate. Make sure it’s not too fast. You don’t want your lathe to throw a tantrum! Finally, do a test run to flaunt your new threading skills.

Troubleshooting Common Thread Cutting Issues

Identifying and resolving common problems. Preventative measures to avoid issues.Fixing thread cutting problems is easier than you think! First, look for signs like uneven threads or snags. These often happen due to improper speed or dull tools. To prevent issues, keep your tools sharp and clean. A few simple steps can help maintain smooth cuts:

- Check settings regularly.

- Use proper lubrication.

- Monitor tool wear.

By staying alert, you can catch problems early and keep your metal lathe running well!

How can I identify thread cutting issues?

Look for symptoms such as chatter, poor thread quality, or tool breakage. Regular inspection and maintenance can help you find these issues quickly.

Maintenance Tips for Compact Metal Lathes

Routine maintenance practices for optimal performance. Importance of keeping the lathe clean and lubricated.Regular care keeps your compact metal lathe working well. Daily cleaning helps to remove dust and chips. This also prevents rust. It’s important to check that all parts are tight. Lubricate moving parts often to avoid wear. Keep your tools sharp for better cuts. A well-maintained lathe runs smooth and helps you make better projects.

How often should I clean and lubricate my lathe?

Clean and lubricate your lathe at least once a week. This helps keep it in top shape.

Routine Maintenance Tips:

- Clean surfaces daily.

- Lubricate moving parts weekly.

- Inspect for wear every month.

- Check and replace tools as needed.

Safety Precautions in Thread Cutting

Key safety guidelines to follow. Recommended personal protective equipment (PPE).Thread cutting can be exciting, but safety is very important. Follow these key safety guidelines:

- Always wear protective goggles. They shield your eyes from flying debris.

- Use gloves to protect your hands from sharp tools.

- Keep your hair tied back and wear tight-fitting clothing.

- Make sure the area is clean and free of clutter.

Using the right personal protective equipment (PPE) is essential:

- Safety goggles

- Cut-resistant gloves

- Dust mask or respirator, if needed

- Steel-toed boots to protect your feet

By following these tips, you can stay safe while enjoying thread cutting!

What should I wear for safety during thread cutting?

Wear safety goggles, cut-resistant gloves, and steel-toed boots to keep safe. It’s important to protect your eyes, hands, and feet while working with tools.

Conclusion

In summary, a compact metal lathe is great for thread cutting. It helps you create accurate, strong threads. Practice using this tool to improve your skills. Always keep safety in mind while working. Explore more about lathes to discover new techniques and projects. By learning and experimenting, you can create amazing things with your lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Thread Cutting:Sure! Here are five questions about compact metal lathe thread cutting: 1. **What is a compact metal lathe?** A compact metal lathe is a small machine. It helps us shape and cut metal. 2. **Why do we cut threads on metal?** We cut threads to help pieces fit together. It makes strong connections, like screws and bolts. 3. **How do we cut threads?** We use a special tool on the lathe. The tool moves along the metal to create threads. 4. **What materials can we use?** You can use different metals like steel or aluminum. They work well for making threaded parts. 5. **What safety tips should we follow?** Always wear safety glasses and keep your hands away from moving parts. It helps keep you safe while working!

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For In A Compact Metal Lathe For Efficient Thread Cutting?When choosing a compact metal lathe for thread cutting, look for a good motor. A strong motor helps make cleaner cuts. You also want easy controls to adjust the speed. An adjustable tailstock is important too, as it helps with accurate work. Finally, a sturdy base keeps everything steady while you work.

How Do You Properly Set Up A Compact Metal Lathe For Threading Operations?To set up a compact metal lathe for threading, you first need to choose the right tool. Make sure you have a threading tool that fits your lathe. Next, tighten the tool in the tool holder securely. Then, adjust the lathe’s speed to a low setting. Finally, carefully measure and set the distances to ensure the metal piece turns correctly for threading.

What Are The Common Types Of Thread Profiles That Can Be Cut On A Compact Metal Lathe?On a compact metal lathe, you can cut different thread profiles. The most common types are square, triangular, and round threads. Square threads look like a box shape. Triangular threads have sharp points, like a mountain. Round threads are smooth and curved. Each thread type is used for different jobs.

What Are The Advantages Of Using A Compact Metal Lathe For Threading Compared To Larger Machines?Using a compact metal lathe for threading has many benefits. First, it takes up less space, so you can fit it anywhere. You can also move it easily if you need to. Compact lathes are usually cheaper, so they save you money. They are perfect for smaller projects, making them great for beginners!

What Safety Precautions Should Be Taken When Performing Thread Cutting On A Compact Metal Lathe?When you use a compact metal lathe for thread cutting, safety is very important. Always wear safety goggles to protect your eyes from flying particles. Keep your hair tied back and wear tight clothing to prevent anything from getting caught in the machine. Make sure your hands stay clear of the cutting area while the lathe is running. Lastly, always follow the instructions carefully and ask an adult if you’re unsure about something.