Have you ever wondered how machines like lathes work? A compact metal lathe is a fantastic tool for crafting precision parts. But have you thought about how all the pieces fit together? Understanding the compact metal lathe wiring diagram is key to unlocking its full potential.

Imagine you’re in your garage, dreaming up a new project. You want to create something amazing, but the lathe seems confusing. What if you could look at a simple wiring diagram? It could guide you through, step by step. This diagram helps you see where each wire connects. It shows you how to power your lathe safely and effectively.

Did you know that even the smallest mistakes in wiring can lead to big problems? That’s why knowing the wiring diagram is so important. It’s like having a map for a treasure hunt. The “treasure” is your perfectly running lathe, ready for your next masterpiece!

Join us as we explore the world of compact metal lathe wiring diagrams. You’ll gain the knowledge to make your projects come to life!

Compact Metal Lathe Wiring Diagram: A Comprehensive Guide

Understanding the Compact Metal Lathe Wiring Diagram

A compact metal lathe wiring diagram shows how to connect electrical parts safely. It includes important symbols to guide users in their projects. By following the diagram, you can avoid mistakes that might break your machine. Did you know that knowing how to wire your lathe can save you money on repairs? Wiring properly also enhances the lathe’s performance, making it a vital skill for any metalworker. Understanding these diagrams can be a game-changer in your machining experience!Understanding Compact Metal Lathes

Definition and purpose of compact metal lathes. Advantages of using compact metal lathes in small workshops.Compact metal lathes are machines that shape metal into specific parts. They spin metal to cut it, making it smooth and even. These lathes are great for small workshops where space is limited. They offer many benefits:

- Efficiency: Compact lathes save time on projects.

- Cost-Effective: They are cheaper than larger machines.

- Easy to Use: Learning to operate them takes less time.

With their small size and strong performance, compact metal lathes help makers create quality work without needing a big shop.

What is a compact metal lathe used for?

Compact metal lathes are used to shape and cut metal into parts. They help create tools, gears, and other objects. These machines fit well in small spaces and make precise parts easily. They are essential for hobbyists and professionals alike.

Components of a Compact Metal Lathe

Key parts involved in the operation. Electrical components and their functions.A compact metal lathe is like the Swiss Army knife of machinery. It has several vital parts working together. Each component plays an important role in making it run smoothly. Key parts include the bed, which holds everything steady; the spindle, where the magic happens; and the carriage, which moves the tool around.

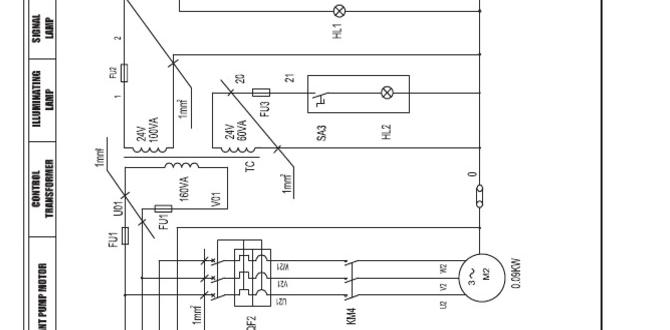

Don’t forget the electrical side! The wiring diagram shows us how everything connects. The motor provides power, while the control panel helps you adjust speed and settings. It’s like a superhero team, working together to create amazing metal shapes!

| Component | Function |

|---|---|

| Bed | Stabilizes the lathe |

| Spindle | Holds and spins the workpiece |

| Carriage | Moves the cutting tool |

| Motor | Provides power |

| Control Panel | Manages settings |

Importance of Wiring Diagrams

How wiring diagrams aid in assembly and troubleshooting. Common wiring mistakes to avoid.Wiring diagrams are like maps for your projects. They show how parts fit together, making assembly and troubleshooting easier. They also help you spot mistakes early, saving time and frustration. Here are some common wiring errors to avoid:

- Missing connections

- Wrong wire colors

- Poor insulation

- Neglecting to double-check

Using accurate diagrams leads to smoother setups and repairs. Always give your tools a thorough check-up!

Why do wiring diagrams matter?

Wiring diagrams help simplify tasks. They guide users, minimize errors, and enhance safety. With a good diagram, you can feel more confident in your work!

Basic Wiring Diagram of a Compact Metal Lathe

Breakdown of a standard wiring diagram. Explanation of symbols and connections used.Understanding a wiring diagram can feel like solving a secret code. Usually, a compact metal lathe diagram showcases various symbols and connections. These symbols represent important components, like motors and switches. Each line shows how these parts connect with each other. For example, a line can mean a wire, just like spaghetti connecting meatballs! Check out the table below for common symbols:

| Symbol | Meaning |

|---|---|

| 🔌 | Power Supply |

| ⚙️ | Motor |

| 🔄 | Switch |

These diagrams also help ensure safety. Following them can prevent surprises, like turning your lathe into a fancy paperweight!

Step-by-Step Guide to Wiring a Compact Metal Lathe

Tools and materials needed for wiring. Detailed wiring procedure.Wiring your compact metal lathe can feel a bit like solving a puzzle—but with fewer missing pieces. First, gather your tools: a screwdriver, wire stripper, and some safety glasses to keep your peepers safe. Next, you’ll need wires, connectors, and a wiring diagram to guide you (because guessing isn’t a great idea). Psst! Remember, safety first, sparks second!

| Tools | Materials |

|---|---|

| Screwdriver | Wires |

| Wire Stripper | Connectors |

| Safety Glasses | Wiring Diagram |

Start by disconnecting power. Next, follow your wiring diagram step-by-step. Connect wires to their matched colors like a friendly game of Twister. Tighten those connections, but don’t go overboard—this isn’t a wrestling match! Finally, double-check your work, plug it in, and watch your lathe spin like a top! With everything in place, you’re ready to create!

Troubleshooting Common Wiring Issues

Identifying and fixing common wiring problems. Tips for maintaining optimal electrical performance.Wiring problems can be tricky, but identifying them is the first step to fixing them. Look for loose connections; they can cause flickering lights. Check for frayed wires—unless you want sparks flying like a fireworks show! Regular maintenance helps keep your lathe happy. Keep connections clean to avoid rust. Below is a quick guide to common wiring issues:

| Issue | Solution |

|---|---|

| Loose Connection | Tighten the screws. |

| Frayed Wires | Replace the damaged section. |

| Short Circuit | Inspect and isolate faulty wires. |

Staying on top of these tasks can lead to a smoother operation and fewer surprises. But remember, if it looks like a wiring monster, call a pro. Safety first!

Safety Precautions During Wiring Process

Essential safety gear and practices. Electrical risks associated with improper wiring.Wiring can be dangerous if not done correctly. Wear essential safety gear, like gloves and goggles. These protect you from electrical shocks and flying debris. Follow these safety practices:

- Always turn off the power before starting.

- Check your tools for damage.

- Use insulated wire and connectors.

Improper wiring can lead to serious electrical risks, like fires or shocks. Stay safe by being careful and following these rules.

What safety gear should I use during wiring?

For wiring, use gloves, goggles, and non-conductive tools. They keep you safe from accidents and injuries.

Additional Resources and References

Recommended manuals and guides for further learning. Online forums and communities for troubleshooting and advice.If you’re diving deeper into the world of compact metal lathes, knowing where to find good resources is key. Check out manuals and guides that explain things step by step, like your favorite recipe book but for metalwork. Online forums are also treasure troves for troubleshooting. It’s like asking your neighbor for help when you get stuck on a tricky homework problem!

| Resource Type | Examples |

|---|---|

| Manuals and Guides | “Metal Lathe Projects” by Michael Smith; “The Complete Metalworker” |

| Online Forums | Metalworking.com; Reddit’s r/Metalworking |

Joining these communities can turn a dull day into an exciting brainstorm. Remember, **nothing beats learning from others!**

Conclusion

In summary, a compact metal lathe wiring diagram is crucial for safe and accurate operation. It helps you understand connections and wiring for efficient use. You should familiarize yourself with these diagrams for better maintenance and troubleshooting. For hands-on learning, consider checking online resources or manuals. Dive in, and explore more about your lathe’s wiring to enhance your skills!FAQs

Here Are Five Related Questions On The Topic Of Compact Metal Lathe Wiring Diagrams:Sure! A compact metal lathe is a machine that helps cut and shape metal. Wiring diagrams show how to connect the wires inside it. These diagrams use pictures and lines to make it easier to understand. If you’re careful and follow the diagrams, you can set up the lathe correctly. Always make sure to turn off the power before you start working!

Sure! Please share the question you’d like me to answer.

What Are The Essential Components Represented In A Compact Metal Lathe Wiring Diagram?A compact metal lathe wiring diagram shows how different parts connect. You will see the motor, which makes the lathe spin. There are switches that help you turn it on and off. Wires carry electricity from one part to another. Finally, there are controllers to adjust the speed and power.

How Do You Interpret The Wiring Connections For The Motor And Control Switch In A Compact Metal Lathe?To understand the wiring for the motor and control switch on a metal lathe, you start by looking at the wires. The wires connect the motor, which makes it spin, to the switch, which controls it. You need to find out which wire goes where. Usually, one wire connects to power, and the other goes to the motor. By following instructions or a diagram, you can see how they fit together to work properly.

What Safety Precautions Should Be Taken When Wiring A Compact Metal Lathe According To Its Wiring Diagram?When wiring a compact metal lathe, you should always unplug it first. Wear safety gloves to protect your hands. Keep your work area clean to avoid accidents. Follow the wiring diagram carefully to connect everything right. Finally, double-check your work before plugging it back in.

How Can You Troubleshoot Common Wiring Issues In A Compact Metal Lathe Using The Wiring Diagram?To fix wiring problems in a compact metal lathe, start by looking at the wiring diagram. This diagram shows where each wire goes. Check for loose or broken wires, and make sure connections are tight. You can also use a multimeter to test if wires are working. If something still doesn’t work, compare it to the diagram again.

Are There Standard Color Codes Used In Wiring Diagrams For Compact Metal Lathes, And What Do They Signify?Yes, there are standard color codes for wiring diagrams in compact metal lathes. Each color helps you know what the wires do. For example, red usually means power, while black is often for ground. Blue can mean a control signal. These colors make it easier for you to understand and fix the machine safely.