Have you ever wondered what makes a metal lathe work so well? The answer often lies in the lathe bed. The lathe bed is the foundation where all the magic happens. Imagine trying to build a tall tower with a shaky base. It just wouldn’t stand. The same goes for metal lathes.

When comparing metal lathe beds, there are many things to think about. Some beds are made from cast iron, while others use steel. Each material has its own benefits. For example, cast iron can absorb vibrations better, while steel is very strong.

Did you know that the thickness of a lathe bed can affect how accurate a machine is? A thicker bed can lead to better and more precise cuts. Think about it: would you trust a seesaw with a thin board? Probably not! This is why the lathe bed comparison matters for both beginners and experts alike.

In this article, we will dive deeper into the world of metal lathe beds. We’ll explore their differences, advantages, and how they can impact your work. So, whether you’re a hobbyist or a seasoned pro, keep reading to discover what makes the right lathe bed for you!

Comparison Metal Lathe Bed: Understanding Types And Features

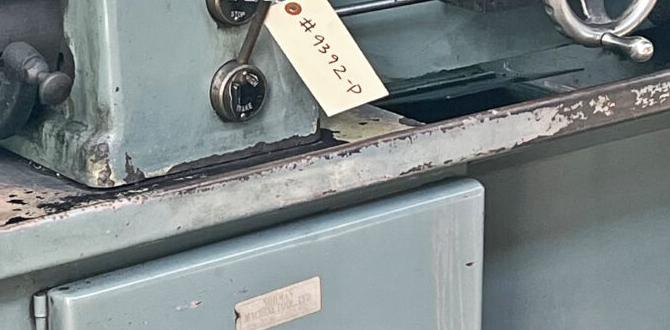

Comparison Metal Lathe Bed

When examining metal lathe beds, you’ll discover key differences in materials and construction. The bed’s strength influences stability and precision during machining tasks. Did you know a heavier lathe bed often absorbs vibrations better, leading to improved accuracy? Additionally, comparing types like cast iron or aluminum can reveal benefits unique to each option. Understanding these factors helps you choose the right lathe for your projects, ensuring you get the best performance and longevity.Types of Metal Lathe Beds

Comparison of cast iron vs. steel beds. Advantages and disadvantages of different bed types.When looking at metal lathe beds, you usually see cast iron and steel being the top choices. Cast iron is like that sturdy friend who can take a hit without flinching. It’s great for absorbing vibrations, meaning smoother work. But, it can be heavy as a whale! On the other hand, steel is lighter and packs a punch in strength. It’s like a light-weight boxer, quick and tough! Here’s a quick comparison:

| Material | Advantages | Disadvantages |

|---|---|---|

| Cast Iron | High vibration absorption, Durable | Very heavy, More brittle |

| Steel | Lightweight, Very strong | Vibration can be an issue, More prone to rust |

Overall, your choice depends on what you need. Want something tough for heavy tasks? Go cast iron! Prefer something light and nimble? Steel is your friend!

Key Factors to Consider When Comparing Metal Lathe Beds

Stiffness and stability: How bed material affects performance. Weight and construction: Impact on vibration and accuracy.When looking at metal lathe beds, focus on stiffness and stability. The material can change performance a lot. Heavier materials prevent wobbles, making your work more accurate, like battling a giant who’s not even wearing pants! The bed’s weight also affects vibration. A solid build can make a big difference. Think of it this way: a shaky bed equals a shaky project. Choose wisely, and you might avoid turning your tool into a karaoke machine!

| Factor | Impact |

|---|---|

| Material | Stiffness and durability |

| Weight | Reduces vibration |

Top Brands and Models of Metal Lathe Beds

Review of leading brands (e.g., Grizzly, Jet, etc.). Specific models and their unique bed features.Some metal lathe beds stand out like rock stars in a band. Brands like Grizzly and Jet are well-known for their quality. Grizzly’s G0602 is a fan favorite for its strong, cast iron bed and compact design. Jet offers the JWL-1221VS, which has a variable speed feature, perfect for those who love to adjust their pace like a cat in a sunbeam. Both brands ensure stability and precision, making them great choices.

| Brand | Model | Unique Features |

|---|---|---|

| Grizzly | G0602 | Strong cast iron bed, compact size |

| Jet | JWL-1221VS | Variable speed control, user-friendly |

Choosing the right bed can be tricky. Remember to look for the features that fit your needs. Having a sturdy base is key to making great pieces, just like a solid foundation for a tree house!

Cost Analysis of Metal Lathe Beds

Price ranges for different bed types and materials. Costbenefit analysis: Performance vs. price.Buying a metal lathe bed can feel like trying to pick the best ice cream flavor—so many choices! Prices for metal lathe beds can vary based on size and materials, ranging from a friendly $500 to a hefty $5,000. Is it worth the splurge? Let’s see! A good bed can help your lathe perform like a pro, while a cheaper option might give you more bumps than a bumpy road. Remember: you generally get what you pay for!

| Type of Bed | Price Range | Performance Quality |

|---|---|---|

| Cast Iron | $1,500 – $5,000 | High |

| Aluminum | $500 – $2,000 | Medium |

| Steel | $700 – $3,500 | High |

In short, look for the right balance between cost and performance. Splurging a bit might give you a smoother ride! After all, who wants a wobbly lathe?

Real User Feedback and Common Issues

Customer satisfaction ratings and reviews. Common problems encountered with specific lathe beds.User feedback can offer real insights into how metal lathe beds perform. Many customers rate their machines highly, especially for durability and accuracy. However, some common issues arise. Users often report:

- Bed warping: A few lathes can lose their shape, affecting accuracy.

- Alignment problems: Some may struggle to stay aligned during use.

- Short warranty periods: Limited coverage can lead to concerns.

These factors influence customer satisfaction. Before buying a lathe, it helps to read reviews and be aware of potential problems.

What do customers say about metal lathe beds?

Many customers appreciate the ease of use and reliability of their machines. However, they also mention the importance of checking the product’s specifications and features.

Maintenance Tips for Prolonging Bed Life

Recommended cleaning and lubrication practices. Preventing wear and damage over time.Keeping your metal lathe bed in great shape is easier than you think! First, set a cleaning schedule. Wipe down the bed after each use to prevent dust from saying, “Hello!” Make sure to lubricate all moving parts with high-quality oil. It keeps things sliding smoothly, like a penguin on ice! Regular lubrication can keep wear and tear at bay. Lastly, inspect your bed often for any signs of damage. Treat it right, and it will last a long time!

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe bed | After every use |

| Lubricate moving parts | Weekly |

| Inspect for damage | Monthly |

Future Trends in Metal Lathe Bed Design

Innovations in materials and engineering. Predictions for the evolution of lathe bed technology.Engineers are working on exciting new materials for lathe beds. These innovations make them stronger and lighter. For example, carbon fiber and aluminum alloys could replace old metals. As technology grows, lathe beds may also get smarter, using sensors to improve precision. Here are some trends to watch for:

- Stronger materials for better durability

- Smart features for increased accuracy

- Eco-friendly designs to reduce waste

Experts believe that by 2030, lathe beds will be faster and more efficient. This could change how we build and create things!

What are the expected advancements in lathe technology?

Future lathe beds will likely be more precise and user-friendly. They may include special tools for easy adjustments and fast setups. This could make machining much easier for everyone!

Conclusion

In summary, comparing metal lathe beds helps you choose the right one for your projects. Remember to consider size, material, and stability. Doing this can improve your work quality and safety. We encourage you to explore different options and read more about the features that matter most to you. Happy turning!FAQs

What Are The Key Differences Between Cast Iron And Steel Lathe Beds In Terms Of Durability And Vibration Absorption?Cast iron lathe beds are very strong and can absorb vibrations well. This means they make less noise when you use them. Steel lathe beds are tough too, but they don’t absorb vibrations as much. Because of this, cast iron is often better for tools that need to be very steady.

How Does The Rigidity Of A Metal Lathe Bed Impact Machining Accuracy And Surface Finish?A metal lathe bed is the long, flat part where everything sits. If the bed is strong and stiff, it helps keep the tools steady. This means we can make cuts that are very precise. When we are precise, we get smoother surfaces on our projects. If the bed isn’t rigid, it can shake or bend, which makes our work less accurate and rougher.

What Are The Advantages And Disadvantages Of Using A Square Vs. Triangular Shaped Bed Design In Metal Lathes?Using a square bed on a metal lathe gives you a lot of space. It’s easy to set up and moves smoothly. However, it can be heavier and harder to lift. A triangular bed is lighter and takes up less space. Sadly, it might not be as stable, which can make work trickier.

How Do Manufacturing Processes (Such As Cnc Machining Vs. Manual Methods) Affect The Quality And Precision Of Metal Lathe Beds?CNC machining uses computer controls to shape metal parts. This makes pieces very precise and consistent. Manual methods rely on human skill, which can vary. Often, CNC machining creates better quality lathe beds than manual methods. When you want accurate and smooth parts, CNC is usually the better choice.

In What Ways Do Modern Materials And Coatings Enhance The Performance And Longevity Of Metal Lathe Beds Compared To Traditional Options?Modern materials and coatings make metal lathe beds stronger and last longer. These new materials resist rust and wear better than old ones. Coatings can help prevent scratches and damage during use. This means we can use the lathe more often without worrying about breaking it. Overall, they help our tools work better and stay in good shape longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences Between Cast Iron And Steel Lathe Beds In Terms Of Durability And Vibration Absorption? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cast iron lathe beds are very strong and can absorb vibrations well. This means they make less noise when you use them. Steel lathe beds are tough too, but they don’t absorb vibrations as much. Because of this, cast iron is often better for tools that need to be very steady.”}},{“@type”: “Question”,”name”: “How Does The Rigidity Of A Metal Lathe Bed Impact Machining Accuracy And Surface Finish? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe bed is the long, flat part where everything sits. If the bed is strong and stiff, it helps keep the tools steady. This means we can make cuts that are very precise. When we are precise, we get smoother surfaces on our projects. If the bed isn’t rigid, it can shake or bend, which makes our work less accurate and rougher.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Square Vs. Triangular Shaped Bed Design In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a square bed on a metal lathe gives you a lot of space. It’s easy to set up and moves smoothly. However, it can be heavier and harder to lift. A triangular bed is lighter and takes up less space. Sadly, it might not be as stable, which can make work trickier.”}},{“@type”: “Question”,”name”: “How Do Manufacturing Processes (Such As Cnc Machining Vs. Manual Methods) Affect The Quality And Precision Of Metal Lathe Beds? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC machining uses computer controls to shape metal parts. This makes pieces very precise and consistent. Manual methods rely on human skill, which can vary. Often, CNC machining creates better quality lathe beds than manual methods. When you want accurate and smooth parts, CNC is usually the better choice.”}},{“@type”: “Question”,”name”: “In What Ways Do Modern Materials And Coatings Enhance The Performance And Longevity Of Metal Lathe Beds Compared To Traditional Options? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern materials and coatings make metal lathe beds stronger and last longer. These new materials resist rust and wear better than old ones. Coatings can help prevent scratches and damage during use. This means we can use the lathe more often without worrying about breaking it. Overall, they help our tools work better and stay in good shape longer!”}}]}