Have you ever wondered how metal parts are made? It’s a bit like magic, but it’s really engineering. A big part of this magic comes from a tool called a lathe. But, not just any lathe will do. The key is in the controller that helps it work. If you want to shape metal precisely, you need a good controller.

A comparison of metal lathe controllers can help you see what makes each one special. Some are simple and easy to use, while others have fancy features. Isn’t it cool to think about how technology helps us create things? Imagine designing your toy or machine part perfectly because you chose the right controller.

In this article, we will dive into the different types of metal lathe controllers. We’ll see how they work and why some are better than others. Get ready to discover which one could help you craft amazing projects! Who knows? Maybe you’ll find the perfect match for your next creation.

Comparison Metal Lathe Controller: Finding The Best Option

Comparison Metal Lathe Controller

Discover the important features of different metal lathe controllers. These devices help machine operators control speed and precision effectively. Key aspects include ease of use, programming options, and compatibility with various tools. Have you ever wondered how some machines create perfect parts? A good controller can make all the difference. Choosing the right one can boost productivity and improve quality. Make informed choices to enhance your metalworking experience!Factors to Consider When Choosing a Metal Lathe Controller

Precision and accuracy in machining. Compatibility with existing machinery.Choosing a metal lathe controller is like picking a pizza topping; you want the right mix! First, consider precision and accuracy in machining. This means your controller should help create parts that fit perfectly. Nobody likes a wobbly wheel! Next, check compatibility with existing machinery. You don’t want a controller that refuses to play nice with your tools. Imagine trying to teach your cat to swim!

| Factor | Importance |

|---|---|

| Precision | Ensures parts fit correctly |

| Compatibility | Allows smooth operation with current tools |

Top Metal Lathe Controllers on the Market

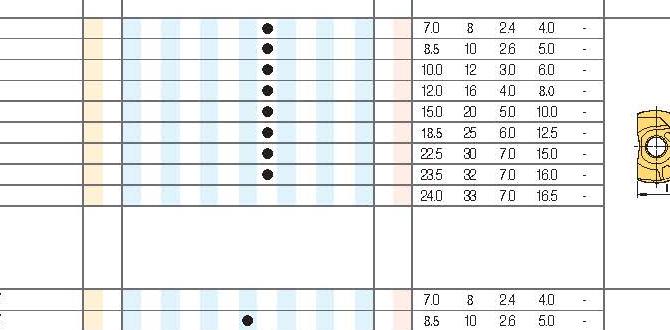

Features and specifications of leading models. Pros and cons of each controller.There are some amazing metal lathe controllers out there. They come with fun features that make machining easier. For example, some models boast user-friendly screens that are bigger than your favorite sandwich! Others have cool settings for different materials and speeds, making them perfect for any project. Here’s a quick look at some of the leading models:

| Controller Model | Features | Pros | Cons |

|---|---|---|---|

| Xiaomi LatheMaster | Touchscreen, precise controls | Easy to use, great support | Pricey for beginners |

| ProMachiner 3000 | Adjustable speeds, solid build | Durable, good for tough jobs | Heavier to move around |

| SimpleTurn | Basic functions, compact | Lightweight, affordable | Limited features |

When picking one, think about what you need. Do you want fancy features or something basic? Decide what suits you best so your lathe doesn’t become a dust collector in the corner!

Control Software and User Experience

Importance of userfriendly interfaces. Comparison of software capabilities.User-friendly interfaces are key in control software. A simple setup saves time and keeps mistakes low. Imagine trying to steer a spaceship with a manual instead of a joystick! The right software can make tasks smooth and even fun.

Compare some software capabilities:

| Software | User-Friendly Score | Features |

|---|---|---|

| EasyTurn | 98% | Basic tools, simple layout |

| ProLathe 3000 | 85% | Advanced tools, steep learning curve |

| LatheMaster | 90% | Good range, decent interface |

As you see, some programs offer more features at the cost of complexity. Finding a balance is like choosing cake over broccoli—delicious wins! In tech, the easier it is to use, the more enjoyable your experience will be.

Performance and Reliability Analysis

How controllers impact lathe performance. Realworld performance metrics.Controllers play a big role in how a lathe works. They help manage speed and precision. Without the right controller, your lathe could be less effective. To measure performance, we look at real-world factors like accuracy, speed, and ease of use. A good controller improves these metrics, leading to higher quality work.

- Accuracy: Does it cut well?

- Speed: Can it work fast?

- Ease of Use: Is it simple to learn?

How do controllers affect lathe performance?

Controllers help improve speed and precision on a lathe. They regulate how the machine operates, ensuring better cuts and smoother work processes.

Price Comparison of Metal Lathe Controllers

Cost ranges of different controller types. Value for money: What to expect at various price points.Metal lathe controllers can vary widely in price. Basic models start around $200. These are great for beginners. Mid-range controllers can cost between $500 and $1,000. They offer better features for serious hobbyists. High-end controllers often exceed $1,500. These are for professionals who need advanced functions.

When choosing a controller, think about:

- Features: More features typically mean a higher price.

- Durability: Higher prices often indicate better build quality.

- Warranty: More expensive models may come with a longer warranty.

Value for money greatly depends on your needs. Higher prices usually offer better performance.

What factors affect the pricing of metal lathe controllers?

Features, brand, and build quality all play key roles in pricing. More advanced controllers have more options.

Customer Reviews and Expert Opinions

Sourcing user experiences and feedback. Summary of expert recommendations.Hearing from people who use metal lathe controllers is important. User reviews share real experiences. Many say that matching features to their needs makes a big difference. Expert opinions shine a light on which controllers stand out. They suggest looking at reliability, price, and ease of use. As one expert said, “A good controller is like a good friend—it helps you, doesn’t judge you, and never runs out of battery!”

| User Experience | Expert Recommendation |

|---|---|

| Reliable controllers boost success. | Choose options with clear instructions. |

| Quick support makes users happy. | Check prices and compare. |

Future Trends in Metal Lathe Controller Technology

Emerging technologies and innovations. Predictions for the future of metal lathe controllers.The world of metal lathe controllers is changing fast! New technologies are popping up like popcorn at a movie. Imagine smart controllers that learn from every spin and cut. They can help you work faster and avoid mistakes. Some predict that in the future, these machines will even talk to each other. That’s right! A metal lathe could chat with your computer about your next project. Exciting, huh?

| Emerging Technologies | Future Predictions |

|---|---|

| AI Integration | Smart, learning machines |

| Remote Monitoring | Machines will communicate |

| 3D Printing | More creative possibilities |

With these trends, we might just be living in a metal lathe wonderland soon! So, keep your eyes open, because the future looks cool and full of shiny gadgets!

Conclusion

In summary, comparing metal lathe controllers helps you find the best fit for your needs. Think about features like precision, ease of use, and price. This guide gets you started, but you can explore more options online. Remember to read reviews and ask questions. You’ll choose a controller that helps you create amazing projects. Happy lathe work!FAQs

What Are The Key Differences Between Cnc Controllers And Manual Controllers For Metal Lathes?CNC controllers use computers to help machines cut metal automatically. This makes it easier and faster. Manual controllers require you to turn knobs and levers by hand. It’s more like driving a car yourself. CNC is great for repeating tasks, while manual gives you more control for unique projects.

How Do Various Metal Lathe Controllers Impact Machining Precision And Efficiency?Different metal lathe controllers can change how well machines work. Some controllers help you make parts more accurately and quickly. They can give you better control over the speed and cuts. This means less waste and better-looking pieces. In short, good controllers make your job easier and faster!

What Features Should Be Prioritized When Selecting A Controller For A Metal Lathe?When we pick a controller for a metal lathe, we should look for easy controls. You want buttons that are simple to understand. It should have clear screens to show information. It’s also good if it can work with different tools. Finally, choose one that has good safety features to keep you safe while working.

How Do Ease Of Use And Programming Capabilities Vary Among Popular Metal Lathe Controllers?Metal lathe controllers help you run machines that shape metal. Some controllers are easy to use, just like a video game. You can learn them quickly. Others have more features, making them useful for advanced projects, but they might be tricky at first. So, choose a controller that fits how skilled you are!

What Are The Benefits And Drawbacks Of Using Open-Source Vs. Proprietary Controllers For Metal Lathes?Open-source controllers help you save money and offer freedom to change settings. You can find help from many people online. However, they may sometimes be tricky to set up. Proprietary controllers are usually easier to use but can cost a lot more and limit what you can change. So, you need to choose what fits your needs best!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences Between Cnc Controllers And Manual Controllers For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC controllers use computers to help machines cut metal automatically. This makes it easier and faster. Manual controllers require you to turn knobs and levers by hand. It’s more like driving a car yourself. CNC is great for repeating tasks, while manual gives you more control for unique projects.”}},{“@type”: “Question”,”name”: “How Do Various Metal Lathe Controllers Impact Machining Precision And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathe controllers can change how well machines work. Some controllers help you make parts more accurately and quickly. They can give you better control over the speed and cuts. This means less waste and better-looking pieces. In short, good controllers make your job easier and faster!”}},{“@type”: “Question”,”name”: “What Features Should Be Prioritized When Selecting A Controller For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we pick a controller for a metal lathe, we should look for easy controls. You want buttons that are simple to understand. It should have clear screens to show information. It’s also good if it can work with different tools. Finally, choose one that has good safety features to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Do Ease Of Use And Programming Capabilities Vary Among Popular Metal Lathe Controllers? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe controllers help you run machines that shape metal. Some controllers are easy to use, just like a video game. You can learn them quickly. Others have more features, making them useful for advanced projects, but they might be tricky at first. So, choose a controller that fits how skilled you are!”}},{“@type”: “Question”,”name”: “What Are The Benefits And Drawbacks Of Using Open-Source Vs. Proprietary Controllers For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Open-source controllers help you save money and offer freedom to change settings. You can find help from many people online. However, they may sometimes be tricky to set up. Proprietary controllers are usually easier to use but can cost a lot more and limit what you can change. So, you need to choose what fits your needs best!”}}]}