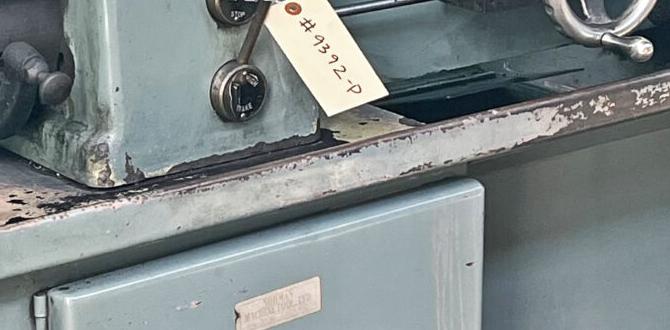

Have you ever wondered how metal parts get their perfect shapes? It all starts with a metal lathe. These machines help create smooth cuts in metal. One important part of a metal lathe is the cross slide. The cross slide lets the tool move side to side easily.

But why should you care about the comparison of metal lathe cross slides? Imagine trying to make a beautiful piece but struggling with your tools. A good cross slide can make a huge difference. It can save you time and frustration.

Did you know that some metal lathes have advanced cross slides that can help make complex shapes? This means you can create cool projects, from tiny gears to large brackets. Knowing how to compare different cross slides helps you pick the best one for your needs.

In this article, we will dive deep into the world of metal lathe cross slides. We will explore the differences and what makes one better than the other. Get ready to discover all the exciting details!

Comparison Metal Lathe Cross Slide: Features And Benefits

Comparison of Metal Lathe Cross Slides

Metal lathe cross slides play a vital role in precision machining. These slides help move the tool or workpiece correctly. When comparing them, consider factors like material, size, and adjustability. Higher quality slides can lead to better accuracy. Did you know? A well-fitted cross slide can reduce errors by up to 30%! Understanding these elements can help you choose the right slide for your lathe and improve your projects.Understanding Metal Lathe Cross Slides

Definition and purpose of cross slides in metal lathes. Key components and materials used in cross slides.A metal lathe cross slide is an essential part of a lathe machine. It helps position the cutting tool. This makes it easier to create precise shapes and sizes in metal. The cross slide moves sideways and connects to the saddle.

Key components of cross slides include:

- Base: Provides support and stability.

- Slider: Moves left and right.

- Handwheel: Controls the movement.

Common materials used for cross slides are steel and aluminum. They are strong yet lightweight. Understanding these parts helps operators make accurate cuts.

What is the purpose of a cross slide in a metal lathe?

The purpose of a cross slide is to guide the cutting tool. It allows for smooth and precise adjustments during machining. This leads to better quality workpieces.

Key Features to Consider When Comparing Cross Slides

Size and compatibility with various lathe models. Precision and accuracy features (lead screws, backlash adjustments).Choosing the right cross slide can change your lathe experience. First, look at the size and how it fits your lathe model. Not every cross slide works with all lathes. Check the fit before you buy! Next, consider how precise the slide is. Lead screws help move the tool smoothly. Backlash adjustments make sure your cuts are accurate. With these factors in mind, you can find the perfect fit for your needs.

What should I look for in a metal lathe cross slide?

Look for size and compatibility first. Then check the precision features like lead screws and backlash adjustments. These will make your work easier and more accurate!

Material Comparisons for Cross Slides

Common materials used (cast iron, aluminum, steel). Impact of material on performance and durability.Choosing a material for a cross slide is important. Different materials affect performance and durability. Here are some common options:

- Cast Iron: Heavy and strong, it absorbs vibrations well. This helps in smooth operations.

- Aluminum: Light and easy to handle. It prevents rust but may wear out faster than heavier materials.

- Steel: Strong yet lightweight. It provides a good balance between durability and performance.

Ultimately, the right choice depends on how you plan to use the lathe.

What material is best for a cross slide?

The best material varies by need. Cast iron is great for stability. Aluminum is perfect for light projects. Steel offers good strength.

Performance Metrics of Cross Slides

Discussion of load capacity and stability. Comparison of operational smoothness and ease of use.Performance of cross slides is vital for metal lathes. Key factors include load capacity and stability. A strong cross slide can handle heavy loads without wobbling. Smooth operation is essential for accurate work. A user-friendly design makes it easier for beginners. Here are the main points:

- Load Capacity: Higher load means better performance.

- Stability: A stable slide reduces mistakes.

- Smooth Operation: Easier to move means better precision.

- Ease of Use: Simple controls help new users learn faster.

What makes cross slides perform well?

A strong cross slide has better load capacity and stability. It also offers smooth operation, making it easier to use, especially for those just starting out.

Cost Factors: Budget vs. Performance

Price ranges for different types of cross slides. Evaluating costeffectiveness based on features and longevity.Prices for cross slides can vary widely. Basic models may cost around $100, while advanced options can reach $600 or more. It’s vital to think about what each cross slide offers. Consider these points:

- Features: More features like durability and precision usually come with a higher price.

- Longevity: Higher-priced cross slides often last longer, saving money in the long run.

Balancing your budget with performance ensures you get the best value for your needs.

What should I consider for cost-effectiveness?

Look for features and durability when comparing prices. A cheaper model may need replacements soon, while an expensive one could save money over time.

User Experiences and Testimonials

Insights from users regarding performance and satisfaction. Common issues or praises mentioned by the lathe community.Users of metal lathes share clear thoughts on their experiences. Many praise their lathe’s precision and smooth operation. Others mention a few hiccups. Common issues involve parts wearing out quickly. Still, most users feel satisfied with their purchase. These devices bring joy to hobbyists and professionals alike.

- Performance praised for its accuracy

- Some face issues with durability

- Overall satisfaction in user groups

What do users say about metal lathes?

Users often highlight great precision and versatility. They enjoy the ease of use and the quality of their projects. Problems are few but can happen with certain brands or models.

Maintenance Tips for Metal Lathe Cross Slides

Best practices for maintaining and preserving functionality. Common pitfalls to avoid during usage and maintenance efforts.To keep your metal lathe cross slide in top shape, follow these simple tips. First, clean it regularly to remove dust and debris. Next, check for wear to keep moving parts smooth. Avoid using too much force; this can cause damage. Also, lubricate the slide to prevent rust. Lastly, store your lathe in a dry place to protect it.

- Clean it often.

- Check for wear regularly.

- Avoid excessive force.

- Lubricate moving parts.

- Store in a dry area.

What are common mistakes when maintaining a metal lathe cross slide?

Many people forget to clean the cross slide often. Others use too much oil, which can attract dirt. Always handle your lathe gently to avoid damaging it. By being careful, you can keep your lathe working well for a long time!

Conclusion

In conclusion, comparing metal lathe cross slides helps you find the best fit for your projects. Look for features like size, material, and ease of use. Understanding these details can improve your metalworking skills. We encourage you to explore more reviews and guides to make informed choices. Happy cutting!FAQs

Here Are Five Questions Related To The Comparison Of Metal Lathe Cross Slides:Sure! I can help with that. Please tell me what the five questions are about comparing metal lathe cross slides, and I will answer them in a simple way.

Sure! Please provide the question you want me to answer.

What Are The Key Differences Between A Dovetail Cross Slide And A Flat Slide Design In Metal Lathes?A dovetail cross slide has a wedge shape. This shape helps keep it steady when you slide it. A flat slide is just flat. It can slide easily but might not be as strong. So, dovetail slides are usually better for precision, while flat slides are simpler and easier to use.

How Does The Material Construction Of A Cross Slide Impact Its Durability And Precision In Metal Lathe Operations?The cross slide helps move the tool in a metal lathe. If it’s made of strong materials like steel, it lasts longer. Strong materials don’t wear out easily, which keeps the tool steady. This steadiness helps us make more precise cuts. So, better materials mean better and more accurate work!

What Are The Advantages And Disadvantages Of Using A Power Feed Cross Slide Versus A Manual Cross Slide?Using a power feed cross slide can be easier and faster. You can control it with a button, so your hands stay free. This makes it great for long projects. However, it’s usually more expensive and can break more easily. A manual cross slide is cheaper and simpler, but it requires more effort to use.

How Does The Size And Weight Of A Metal Lathe’S Cross Slide Affect Its Performance And Stability During Machining?The cross slide on a metal lathe helps move the tool up and down or side to side. If the cross slide is bigger and heavier, it stays steadier while you work. This means the tool cuts better and makes smoother shapes. A lightweight slide might shake and cause mistakes, so size and weight really matter!

In Terms Of Maintenance, What Are The Best Practices For Ensuring The Longevity Of A Metal Lathe Cross Slide?To keep a metal lathe cross slide working well, you should clean it often. Use a soft cloth to wipe away dust and metal shavings. Apply light oil to the slide parts so they move smoothly. Check for any loose screws and tighten them if needed. Lastly, store it in a dry place to prevent rust.