Have you ever wondered how metal lathes work? These machines can shape metal into incredible forms. But, did you know that the drive system plays a key role in their performance? Choosing the right drive system can make all the difference in how well a metal lathe operates.

Imagine trying to ride a bicycle with a broken chain. It wouldn’t work very well, right? The drive system in a metal lathe is just as important. It helps the machine spin and move smoothly. There are different types of drive systems available, each with its own benefits.

Let’s dive into a fun comparison of metal lathe drive systems. By the end, you’ll see which option could help you create amazing projects. Are you ready to learn more about what makes these machines tick?

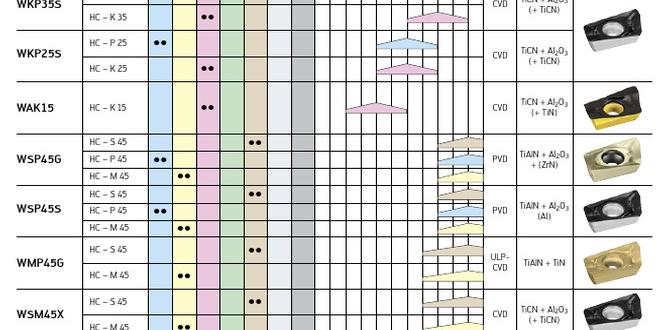

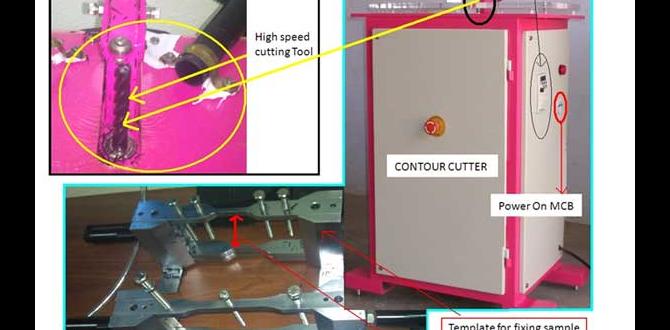

Comparison Of Metal Lathe Drive Systems: Which Is Best? — When Looking To Invest In A Metal Lathe, Understanding The Different Drive Systems Available Is Crucial For Making An Informed Decision. Metal Lathe Drive Systems Are Fundamental Components That Affect Not Only Machining Precision But Also The Overall Efficiency Of The Operation. This Article Will Delve Into The Various Types Of Drive Systems, Outlining Their Advantages And Disadvantages, And Helping You Determine Which Is Best For Your Specific Needs. Types Of Metal Lathe Drive Systems 1. **Mechanical Drive Systems** Mechanical Systems Are Perhaps The Simplest Among Drive Methods. They Use Gears And Belts To Transfer Power From The Motor To The Lathe Spindle. This Direct Drive Approach Is Often Easy To Repair, Provides Consistent Torque, And Is Favored For Its Reliability In Various Machining Applications. However, Speed Adjustments Might Require Manual Changes In The Gear Setups, Making It Less Versatile Than Some Modern Alternatives. 2. **Electronic Variable Speed Drive Systems (Vsd)** Electronic Variable Speed Drives Utilize Electronic Controls To Adjust The Spindle’S Speed, Allowing For Seamless Transitions Between Different Rpms. This System Is Now Becoming More Widespread And Offers Significant Advantages In Terms Of Efficiency And Ease Of Use. Vsd Systems Generally Provide Superior Torque At Lower Speeds And Are Ideal For Projects Requiring Varied Machining Conditions. However, They Can Be More Complex And Expensive To Maintain. 3. **Servo Drive Systems** Servo Drives Are Designed For High-Performance Applications, Offering Exceptional Precision And Control Over The Lathe’S Movements. They Use Feedback Systems To Provide Real-Time Adjustments, Which Facilitates More Intricate Machining Tasks. While These Systems Are Advanced And Often Necessary For Professional-Grade Lathes, They Can Come With A Higher Initial Investment And Maintenance Costs. Comparison Factors In Metal Lathe Drive Systems When Comparing Different Metal Lathe Drive Systems, Consider The Following Factors: – **Cost**: Mechanical Systems Frequently Cost Less, But Advanced Options Like Servo Drives May Lead To Higher Efficiency And Longer-Term Savings. – **Ease Of Use**: Electronic Systems Offer Ease Of Speed Adjustment, While Mechanical Systems Require More Manual Involvement. – **Maintenance**: Mechanical Systems Tend To Be Simpler And Cheaper To Repair, But Electronic Systems Can Provide Better Long-Term Performance If Well-Maintained. – **Applications**: Think About What Types Of Projects You Plan To Undertake. A High-Precision Job May Warrant Investing In A Servo Drive, While Hobbyists May Find A Straightforward Mechanical System Sufficient. Conclusion In Conclusion, The Choice Between Different Metal Lathe Drive Systems Largely Depends On Your Specific Needs, Budget, And The Complexity Of Your Projects. By Thoroughly Comparing These Systems, You Can Make An Informed Decision That Aligns With Your Machining Requirements. Whether You Opt For A Simple Mechanical Drive Or A Sophisticated Servo System, Understanding The Nuances Of Each Can Lead To Improved Productivity And Craftsmanship In Your Metalworking Endeavors.

Comparison of Metal Lathe Drive Systems

Choosing the right metal lathe drive system can be tricky. You might wonder, what’s the difference between gears and belts? Each system has its strengths. Gear systems provide more torque, while belt drives are quieter and smoother. Did you know that some lathes have variable speed settings? This allows for precise adjustments. Understanding these differences helps you pick the perfect lathe for your needs. Making the right choice can change your metalworking experience forever!Types of Drive Systems for Metal Lathes

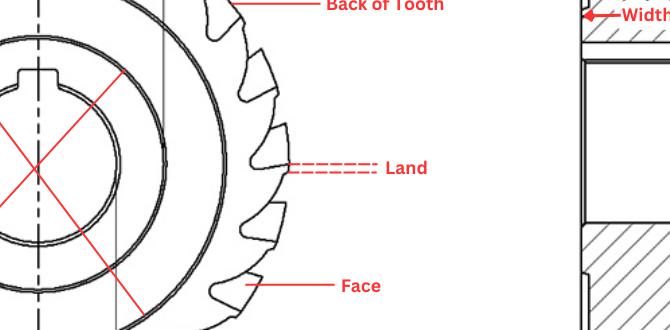

Gear Drive Systems. Description and functionality. Advantages and disadvantages. Belt Drive Systems. Description and functionality. Advantages and disadvantages. Direct Drive Systems. Description and functionality. Advantages and disadvantages.Metal lathes use different drive systems to turn metal, each with its quirks. Gear drive systems use gears to transfer power, offering precise control. However, they can be noisy and need lots of maintenance. Belt drive systems use belts to connect the motor to the lathe. They’re quiet and easy to adjust, but belts wear out over time. Lastly, direct drive systems connect the motor directly to the spindle for smooth operation but can be pricey. Here’s a table to break it down:

| Drive System | Advantages | Disadvantages |

|---|---|---|

| Gear Drive | Precise control | Noisy, high maintenance |

| Belt Drive | Quiet, easy adjustment | Belt wear |

| Direct Drive | Smooth operation | Costly |

In the end, choosing a drive system is like picking your favorite ice cream flavor—each has its own taste!

Performance Metrics for Drive Systems

Torque and power output. Speed variability and control. Maintenance requirements.When evaluating drive systems, it’s crucial to look at several performance metrics. First, there’s torque and power output, which determine how much work the system can handle. More torque means more power, making it easier to tackle tough materials. Then we have speed variability and control; it’s important for smooth operation and precision. Lastly, don’t forget maintenance requirements, as a low-maintenance system saves time and trouble!

| Performance Metric | Importance |

|---|---|

| Torque | More torque equals more power for tough jobs. |

| Speed Control | Allows for precise and smooth machining. |

| Maintenance | Less maintenance means more time for fun (and less grease under your nails). |

Comparative Analysis: Gear vs. Belt vs. Direct Drive

Performance comparison across different tasks. Cost analysis for each drive system type. Durability and lifespan considerations.The choice between gear, belt, and direct drive systems can be like choosing pizza toppings; everyone has their favorite! For performance, gears handle heavy-duty tasks best, while belts are great for lighter jobs. Direct drive is quick and straightforward, making it a crowd-pleaser.

Cost is another big factor. Generally, gear systems can be pricier due to their complexity. Belts are more budget-friendly, and direct drive systems are often the middle ground—affordable but efficient. Durability is key, too! Gears can last long, belts may wear out faster, while direct drive systems are tough and reliable.

| Drive System | Performance | Cost | Durability |

|---|---|---|---|

| Gear | Best for heavy tasks | Higher | Very durable |

| Belt | Good for light tasks | Budget-friendly | Can wear out |

| Direct Drive | Fast and efficient | Moderate | Reliable and tough |

In the end, your choice depends on your project needs, just like that choice between pepperoni and pineapple!

Choosing the Right Drive System for Your Needs

Factors to consider based on usage (hobbyist vs. industrial). Recommendations for various applications.Picking a drive system can feel like choosing between pizza toppings—everyone has their favorite! If you’re a hobbyist, you might want something simple and affordable, like a belt drive. It’s easy to use and does a decent job for small projects. Conversely, if you’re in the big leagues—think factories—an industrial setup with a gear drive is better. It’s tough, durable, and works hard. Here’s a quick guide:

| Usage Type | Recommended Drive System | Reason |

|---|---|---|

| Hobbyist | Belt Drive | Easy and cost-effective |

| Industrial | Gear Drive | Strong and reliable |

Choosing wisely can save time and effort! Happy turning!

Innovations and Trends in Metal Lathe Drive Systems

Latest advancements in technology. Future trends to watch for in drive system design.New technology is changing metal lathe drive systems. Smart tools and automation are becoming common. These innovations make lathes more efficient and precise. Imagine machines that can talk to each other to improve work. This trend will keep growing in the future. Here are some key points to watch:

- Advanced Sensors: Help in monitoring and controlling operations.

- Energy Efficient Designs: Save power and reduce costs.

- Modular Systems: Allow easy upgrades and repairs.

What future trends should we expect in metal lathe drive systems?

Future trends include smarter materials, better energy efficiency, and advanced automation.

Common Mistakes to Avoid When Selecting a Drive System

Pitfalls in performance expectations. Misjudging costeffectiveness.Choosing the right drive system can feel like a treasure hunt. But beware—the path is full of traps! For starters, don’t expect your new system to magically turn you into a production wizard overnight. Some folks overestimate what different systems can do. It’s like thinking your toy car can zoom like a Ferrari!

Then, there’s the money game. It’s easy to get excited and forget to check those pesky costs. Sometimes, the cheapest option isn’t the best deal. It might cost you more in repairs later, like finding out that your budget pizza comes with extra toppings of regret. Remember, investing wisely can save you from buyer’s remorse!

| Common Mistakes | Example |

|---|---|

| High Performance Expectations | Thinking a basic model can handle heavy work. |

| Misjudging Costs | Choosing a cheap option that fails early. |

Expert Tips for Maintaining Your Metal Lathe Drive System

Routine maintenance best practices. Signs that indicate issues or failures.Keeping your metal lathe drive system in top shape is key! Regular maintenance is like brushing your teeth; skip it, and you’ll regret it later. Check for oil leaks and strange noises. These could mean trouble ahead. Also, clean the components every now and then. Dust isn’t just for decorating your shelves! Look out for wear and tear in belts or gears. Trust us, it’s better to fix it now than to deal with a breakdown later!

| Routine Maintenance Tips | Signs of Issues |

|---|---|

| Check lubrication regularly. | Unusual vibrations or noises. |

| Clear dust from parts. | Difficulty in turning the handle. |

| Inspect belts for wear. | Oil leaks or spots. |

Conclusion

In conclusion, understanding metal lathe drive systems helps you choose the right one for your projects. We explored gear-driven and belt-driven systems, each with unique benefits. You can improve your machining skills by knowing these differences. Consider experimenting with both types in your next project. For more detailed information, check out articles or videos on metal lathe systems.FAQs

What Are The Primary Differences Between A Belt-Driven And A Direct-Drive System In Metal Lathes Regarding Efficiency And Maintenance Requirements?Belt-driven systems use belts to connect the motor to the machine. They can lose power, making them less efficient. You need to check and replace belts sometimes. Direct-drive systems connect the motor directly, so they are more efficient. They usually need less maintenance because there are no belts to wear out.

Sure! Please provide the question you would like me to answer.

How Does The Power Transmission In A Variable-Speed Metal Lathe Affect Its Performance Compared To A Fixed-Speed Model?In a variable-speed metal lathe, you can change the speed easily. This helps you work better on different materials. It can cut fast or slow, depending on what you need. A fixed-speed model can only work at one speed, which might not be best for every job. So, with a variable-speed lathe, you get better results and more options!

Sure! Please let me know what question you would like me to answer.

What Are The Advantages And Disadvantages Of Using A Gear-Driven System Versus A Belt-Driven System In Terms Of Torque Delivery And Precision?A gear-driven system uses gears to move power, while a belt-driven system uses belts. Gears usually give better torque delivery, meaning they can move heavy things more easily. They also help things stay in place better, so they are more precise. However, gears can be noisier and need more care. Belts are quieter and cheaper but can slip and may not deliver power as well.

Sure! Please provide the question you’d like me to answer.

How Do Different Drive Systems Impact The Overall Cost And Longevity Of A Metal Lathe, Particularly For Industrial Versus Hobbyist Applications?Different drive systems can change how much a metal lathe costs and how long it lasts. Industrial lathes usually have stronger drives. This means they can run longer and handle tougher jobs. Hobbyist lathes are cheaper but may wear out faster, especially if you use them a lot. Choosing the right drive system helps you get the best value for your needs.

Sure! Please provide the question you’d like me to answer.

In What Scenarios Might A Cnc Lathe’S Servo Motor Drive System Outperform A Traditional Mechanical Drive System In Terms Of Accuracy And Flexibility?A CNC lathe uses a special motor called a servo motor instead of gears. This helps it move very smoothly and exactly. When we need to make tiny, precise shapes, the servo motor does a better job. It’s also more flexible because it can change how it moves easily for different tasks. This means you can create more designs without needing new parts.