Have you ever wondered how tiny metal parts are made? A metal lathe is a powerful tool that helps shape metal into many forms. But not all metal lathes are the same. Some have gears that make them work better. This article will dive into the comparison of metal lathe gears.

Think about your favorite toy. If it has moving parts, gears might be involved. Just like with toys, gears in metal lathes help machines run smoothly and efficiently. Understanding these differences can help you choose the right lathe for your needs.

Did you know that some metal lathes can cut metal twice as fast as others? It’s all about the gear system they use. This article will help you explore the world of metal lathe gears. Get ready to discover what makes each one unique and important!

Comparison Metal Lathe Gear: Choosing The Right Option

Comparison Metal Lathe Gear

When choosing a metal lathe, understanding the gear comparison is crucial. Different gears affect how quickly and smoothly the lathe operates. For instance, a lathe with a high gear ratio can work faster, but may lack torque. On the flip side, lower gear ratios provide more strength for tougher materials. Considering your projects and needs will help you find the perfect balance. Did you know some lathes even offer variable speeds? This can make a big difference!Understanding Metal Lathe Gear Types

Description of gear types: spur, helical, bevel, etc.. Advantages and disadvantages of each gear type..Different types of gears work together in metal lathes. Each gear has its own job, making functions easier. Here’s a quick look at some gear types:

- Spur Gears: Simple and cost-effective. Easy to make, but can be noisy.

- Helical Gears: Quiet and smooth. They push against each other, but can wear out faster.

- Bevel Gears: Change direction of motion. They may need extra space, which can be a drawback.

Each type has its benefits and flaws. Choosing the right gear helps the lathe perform well.

What are the advantages and disadvantages of different gear types?

The advantages and disadvantages of gears differ. For example, spur gears are cheap but loud. Helical gears are quieter but can wear quickly. Bevel gears work great but need more room. Understanding these can help in choosing the best gear.

Essential Features of Metal Lathe Gears

Material choices: steel, cast iron, and composites.. Gear ratio implications on performance and speed..Choosing the right material for metal lathe gears is key. You can pick from steel, cast iron, and composites. Steel is strong and durable, perfect for tough jobs. Cast iron is heavy and stable, making it great for vibrations. Composites are light and resistant to wear, but might miss that raw power. The gear ratio plays a big role too. A higher ratio means faster speeds. But watch out, too high can lead to less torque, like trying to run in quicksand!

| Material | Description |

|---|---|

| Steel | Strong and tough, ideal for heavy workloads. |

| Cast Iron | Stable and great for reducing vibrations. |

| Composites | Light and wears well but less powerful. |

Performance Factors in Gear Selection

Impact of gear design on precision and accuracy.. Influence of gear play and backlash on lathe operation..Choosing the right gears affects how well a lathe works. Good gear design helps make cuts precise and accurate. Poor design can lead to mistakes. Gear play and backlash also matter. They can cause movement delays and reduce quality. A small amount of play can be okay, but too much makes things tricky. Keeping these factors in check improves performance and helps create better projects.

How does gear design affect precision?

Good gear design is crucial for achieving precise cuts. It helps keep the lathe on track and reduce errors.

Key points to remember:

- Strong gear design = better accuracy.

- Avoid excess gear play for smoother operation.

- Check backlash regularly to maintain quality.

Cost Analysis of Metal Lathe Gears

Price ranges for different gear types and materials.. Costbenefit analysis of investing in higherquality gears..Different metal lathe gears come with different prices. Prices vary based on the gear type and the materials used. For example, simple plastic gears can cost around $10. In contrast, high-quality steel gears may range from $50 to $200. Investing in better gears often means better performance. Higher quality gears can last longer and work better. Check the benefits before choosing gears. Here’s a quick cost summary:

- Plastic Gears: $10

- Aluminum Gears: $30

- Steel Gears: $50-$200

Is it worth paying more for quality gears?

Yes, higher-quality gears often last longer and work better. They may cost more upfront, but they can save you money in repairs and replacements over time.

Maintenance Tips for Longevity of Lathe Gears

Recommended practices for gear upkeep and inspection.. Common issues and troubleshooting guidelines for users..Taking care of your lathe gears is like giving them a spa day! Regular cleaning is key to keeping them happy. Check for cracks or rough spots that might cause trouble later. Dust and grime can turn into troublemakers, so clean them often. If you hear a funny noise, that’s not a ghost—it’s time to investigate! Use this handy table for common gear issues:

| Issue | Action |

|---|---|

| Strange noises | Inspect for loose parts. |

| Excess wear | Apply proper lubrication. |

| Dirt buildup | Clean gears regularly. |

Remember, keeping those gears in shape helps them last longer. After all, no one wants to go through gear drama when they’re trying to create something amazing!

Case Studies: Gear Failures and Solutions

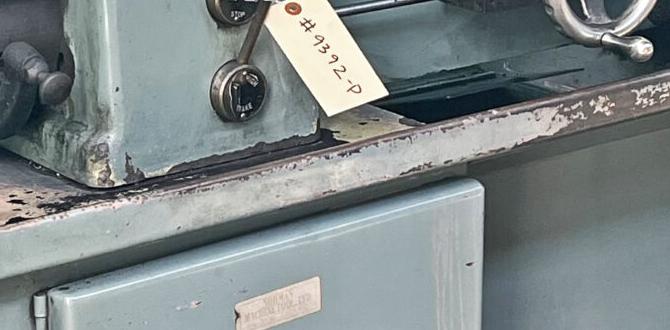

Examples of gearrelated failures in metal lathes.. Solutions and modifications to improve gear reliability..Gear problems can hurt metal lathes. Many users face issues like breaks or misalignments. These problems can slow down work and cost money. Here are some examples and their solutions:

- Low-quality gears crack under pressure.

- Improper lubrication causes gears to overheat.

- Old gears wear out quickly.

To make gears stronger, consider these fixes:

- Use high-quality materials.

- Apply proper lubrication regularly.

- Upgrade to modern gear designs.

With these changes, metal lathe users can improve gear performance and lower failure rates.

What are common gear failures in metal lathes?

Common gear failures include breaks, wear, and misalignments. These issues can happen due to poor quality, lack of maintenance, or improper use.

How can gear reliability be improved?

Improve reliability by using better materials, lubricating them properly, and upgrading designs. These changes can help prevent common gear problems.

Conclusion

In conclusion, comparing metal lathe gears helps you choose the best option for your projects. Different types affect accuracy and performance. We recommend researching brands and reading reviews to make informed decisions. Think about your needs and budget. For more insights, explore articles or guides on lathe gears. This will ensure your next project runs smoothly and successfully!FAQs

What Are The Key Differences Between A Gear-Driven Metal Lathe And A Belt-Driven Metal Lathe In Terms Of Performance And Maintenance?A gear-driven metal lathe uses gears to turn the machine, making it strong and precise. A belt-driven lathe relies on belts, which can wear out faster and need replacing. In terms of performance, gear-driven lathes usually run smoother and are better for heavy work. For maintenance, belt-driven lathes need more attention since belts can slip or break. Overall, gear-driven ones are often easier to keep running well.

How Does The Number Of Gears In A Metal Lathe Affect Its Versatility And Ability To Cut Different Materials?The number of gears in a metal lathe helps it cut different materials better. Each gear lets the lathe spin at different speeds. More gears mean you can change speeds easily, helping you work on soft or hard materials. This makes the lathe more versatile, so you can use it for many projects. The right gear helps you get the best results every time!

What Are The Advantages Of Using A Variable Speed Gear System In Metal Lathes Compared To Fixed Gear Ratios?Using a variable speed gear system in metal lathes is really cool! It lets you change the speed easily. This means you can work faster or slower depending on what you need. Fixed gear ratios stay the same, which can make it harder to do different tasks. With variable speed, you have more control and can make better things!

How Can Gear Wear And Tear Impact The Precision And Accuracy Of A Metal Lathe Over Time?As gears wear out on a metal lathe, they can become loose or rough. This makes the machine harder to control. If you try to cut metal, your results might not be exact. You might end up with parts that don’t fit together well. Keeping the gears in good shape helps keep your work accurate and precise.

What Factors Should Be Considered When Comparing The Gear Systems Of Different Brands And Models Of Metal Lathes?When comparing the gear systems of different metal lathes, you should look at a few things. First, check how many gears each lathe has. More gears usually mean more options for speed and power. Next, see how easy it is to change gears. Some lathes let you switch gears quickly and easily. Finally, think about how strong the gears are; you want them to last a long time.