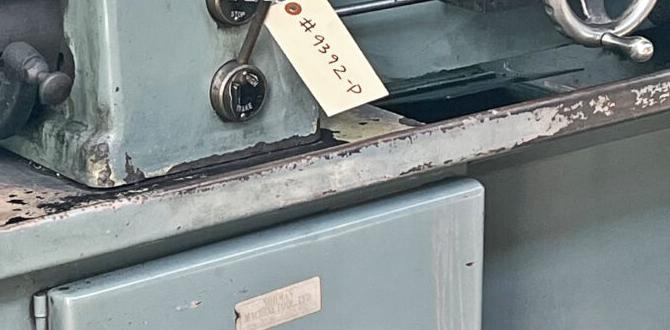

Imagine you’re in a workshop, surrounded by buzzing tools and the smell of metal shavings. You see a worker turning a knob on a metal lathe, adjusting it with a smooth handwheel. Have you ever wondered how important that handwheel is?

The comparison of a metal lathe’s handwheel can reveal a lot about its design and function. Different handwheels may look the same, but they feel different when you use them. Why does that matter? The right handwheel can make your work easier and more precise.

Did you know that some handwheels are made of special materials to reduce friction? This helps them turn more smoothly. Choosing the best one can change your entire project.

Join us as we explore the fascinating world of metal lathe handwheels. We’ll compare different options and find out which one can truly make your work better. Get ready to discover how a simple tool can make a big difference!

Comparison Metal Lathe Handwheel: Types, Features, And Benefits

Comparison Metal Lathe Handwheel

When you’re using a metal lathe, the handwheel plays a key role. It lets you move the cutting tool smoothly for precision. Different handwheels offer varying sizes and materials, impacting control and comfort. Have you ever struggled with a tricky cut? Choosing the right handwheel can solve that problem. Some handwheels even include markings for easier measurements. Finding the best fit for your work style can make all the difference in your projects.Understanding Handwheel Functionality

Explanation of handwheel mechanics in metal lathes. Importance of handwheel design for precision machining.A handwheel plays a crucial role in metal lathes. It helps control the movement of the machine. By turning the handwheel, users can adjust cutting tools with precision. This control is vital for creating accurate shapes and sizes in metalwork. A well-designed handwheel can make machining smooth and efficient.

Good handwheel design ensures:

- Easy grip and maneuverability

- Clear markings for measurements

- Stable movement for consistent results

In short, a functional handwheel directly impacts the quality of the final product.

Why is the design of a handwheel so important?

The design of a handwheel is important because it affects accuracy and ease of use. A better design helps users work faster and more precisely.

Material Composition of Handwheels

Comparison of materials (e.g., aluminum, steel, plastic). Impact of material on durability and performance.Handwheels can be made from different materials. Each material affects how the handwheel works and lasts over time. Here’s a quick look:

- Aluminum: Lightweight and easy to handle. It resists rust but may wear out faster than other materials.

- Steel: Strong and durable. It lasts a long time but can be heavier to turn.

- Plastic: Very lightweight and cheap. It may break more easily compared to metal options.

Choosing the right material matters. A stronger handwheel improves performance. This way, you can work better for longer periods!

Why is material choice important for handwheels?

The material affects durability and performance. Stronger materials lead to better performance and longer life for the handwheel.

Size and Ergonomics

Importance of wheel size for operator comfort and control. Ergonomic designs: How they improve usability.Choosing the right wheel size affects how comfortable you feel while working. A larger wheel makes it easier to control movements. This means fewer trips to the chiropractor! Ergonomic designs, like those comfy handles, help you grip better and reduce tired hands. An awesome tool can be your best buddy, but if it hurts to hold, it might turn into your worst enemy. A happy operator means a happy machine!

| Wheel Size | Comfort | Control |

|---|---|---|

| Small | Painful for long use | Less control |

| Medium | Okay for most tasks | Good control |

| Large | Comfortable | Best control |

Compatibility with Different Lathe Models

Factors to consider for ensuring the right fit. Examples of popular lathe models and their handwheel options.Choosing the right handwheel for your metal lathe can feel like finding the perfect sock in a messy drawer! Many factors come into play. First, check the size and threading of your lathe’s spindle. Your handwheel must fit these measurements snugly. Popular models like the Grizzly G4003 and Jet JWL-1442 offer great handwheel options, making them favorites among hobbyists and pros alike.

| Lathe Model | Compatible Handwheel Options |

|---|---|

| Grizzly G4003 | 12″ Handwheel A, 10″ Handwheel B |

| Jet JWL-1442 | 14″ Handwheel C, 12″ Handwheel D |

Remember, a handwheel that’s too loose is like wearing flip-flops in the snow—just not a good idea!

Price Range and Value Analysis

Comparison of handwheel prices across different brands. Evaluating cost vs. benefits for budgetconscious users.Different brands of handwheels come with various price tags. Some are as cheap as a bag of chips, while others might cost more than your lunch money! Usually, you get what you pay for. A budget-friendly option might save money now, but could cost you later if it breaks easily. Analyzing cost against benefits is key, especially for those on a tight budget. Here’s a quick table to visualize the options:

| Brand | Price | Features |

|---|---|---|

| Brand A | $50 | Basic design, lightweight |

| Brand B | $80 | Durable, extra features |

| Brand C | $120 | High quality, long-lasting |

In short, weigh your options carefully. Remember, the best handwheel isn’t always the priciest one, but it should fit your needs while keeping your wallet happy!

User Reviews and Recommendations

Summary of user experiences for toprated handwheels. Highlighting expert recommendations and ratings.User experiences highlight a mix of joy and some gripes when it comes to top-rated handwheels. Many users praise the smooth motion and sturdy feel, making lathe work a breeze. On the flip side, a few folks find adjustments a little tricky, like solving a puzzle blindfolded! Experts recommend models with solid build quality and high customer ratings. Here’s a quick peek at some favorites:

| Handwheel Model | User Rating | Expert Recommendation |

|---|---|---|

| Precision Lathe 3000 | 4.8 ★ | Highly recommended for beginners! |

| ProMach 500 | 4.6 ★ | Great for professionals. Durable! |

| EasyTurn 200 | 4.4 ★ | Good for those who love smooth handling. |

In summary, the best handwheels often combine user-friendly design with expert feedback. So, whether you’re a hobbyist or a pro, there’s a handwheel waiting to make your metal crafting experience smoother and way more enjoyable!

Maintenance and Care for Longevity

Tips for keeping handwheels in optimal condition. Common issues and troubleshooting advice.Keeping your handwheels happy is essential for a smooth metal lathe experience. Start with regular cleaning to prevent grime and dust from throwing a party on your machine. A little lubricant can make the difference between a squeaky wheel and a smooth operator. If your handwheel feels stiff, it might be time for a little TLC. Check for loose screws or dirt buildup; it’s like a spring cleaning for your lathe!

| Common Issues | Troubleshooting Tips |

|---|---|

| Squeaking noise | Apply lubricant and tighten screws. |

| Stiff movement | Clean dirt and check for obstructions. |

| Wobbly handwheel | Inspect for loose parts and tighten them. |

Remember, a well-maintained handwheel can last for years, maybe even outlive your favorite pair of socks! So, give it the care it deserves.

Conclusion

In summary, comparing metal lathe handwheels helps you select the best one for your needs. A good handwheel improves your control and precision. Consider factors like size, material, and grip. We encourage you to explore different options and read reviews. The right handwheel can make your projects easier and more enjoyable. Start your search today!FAQs

What Are The Key Differences In Design And Functionality Between Manual And Cnc Metal Lathe Handwheels?Manual handwheels let you control the lathe by turning them by hand. You feel the machine and make precise movements. CNC, which stands for Computer Numerical Control, uses buttons and a screen instead of handwheels. It moves automatically based on computer instructions. This makes CNC lathes faster and can repeat tasks without needing your hands.

How Does The Size And Weight Of A Handwheel Affect The Precision And Ease Of Use In Metal Lathe Operations?The size and weight of a handwheel can change how easy it is to use a metal lathe. A bigger handwheel usually gives you more control, making it easier to be precise. If the handwheel is heavy, it might be harder to turn, but it can help keep the machine steady. So, choosing the right handwheel helps us work better and more accurately.

What Materials Are Commonly Used In The Construction Of Metal Lathe Handwheels, And How Do They Impact Durability And Performance?Metal lathe handwheels are often made from cast iron or aluminum. Cast iron is strong and can handle heavy use, which makes it very durable. Aluminum is lighter, making it easier to turn, but it can wear down faster. Both materials help the handwheel work well by providing a good grip and smooth movement.

How Do Ergonomic Features Of Handwheels Influence User Comfort And Control During Machining Tasks On A Metal Lathe?Ergonomic handwheels make it easier for you to turn them. They fit your hand well and reduce strain. This means you can work longer without feeling tired. Good handwheels also give you better control over the machine. You can be more precise while working on the metal lathe.

In What Ways Can Customization Or Upgrades To A Metal Lathe Handwheel Improve Machining Efficiency And Accuracy?Customizing or upgrading a metal lathe handwheel can make it easier to turn. When you change the handwheel, you can get better control. This helps you cut metal more precisely. A better handwheel can also make it quicker to adjust settings. Overall, these changes can help you work faster and make better parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences In Design And Functionality Between Manual And Cnc Metal Lathe Handwheels? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual handwheels let you control the lathe by turning them by hand. You feel the machine and make precise movements. CNC, which stands for Computer Numerical Control, uses buttons and a screen instead of handwheels. It moves automatically based on computer instructions. This makes CNC lathes faster and can repeat tasks without needing your hands.”}},{“@type”: “Question”,”name”: “How Does The Size And Weight Of A Handwheel Affect The Precision And Ease Of Use In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and weight of a handwheel can change how easy it is to use a metal lathe. A bigger handwheel usually gives you more control, making it easier to be precise. If the handwheel is heavy, it might be harder to turn, but it can help keep the machine steady. So, choosing the right handwheel helps us work better and more accurately.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Metal Lathe Handwheels, And How Do They Impact Durability And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe handwheels are often made from cast iron or aluminum. Cast iron is strong and can handle heavy use, which makes it very durable. Aluminum is lighter, making it easier to turn, but it can wear down faster. Both materials help the handwheel work well by providing a good grip and smooth movement.”}},{“@type”: “Question”,”name”: “How Do Ergonomic Features Of Handwheels Influence User Comfort And Control During Machining Tasks On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Ergonomic handwheels make it easier for you to turn them. They fit your hand well and reduce strain. This means you can work longer without feeling tired. Good handwheels also give you better control over the machine. You can be more precise while working on the metal lathe.”}},{“@type”: “Question”,”name”: “In What Ways Can Customization Or Upgrades To A Metal Lathe Handwheel Improve Machining Efficiency And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Customizing or upgrading a metal lathe handwheel can make it easier to turn. When you change the handwheel, you can get better control. This helps you cut metal more precisely. A better handwheel can also make it quicker to adjust settings. Overall, these changes can help you work faster and make better parts.”}}]}