Comparison Of Metal Lathe Lead Screw: Key Features And Benefits

Comparison of Metal Lathe Lead Screws

When choosing a metal lathe, understanding lead screws is essential. They guide the tool to create precise cuts. Different materials can affect durability and performance. For instance, brass lead screws often provide smooth movement. In contrast, steel is tougher but may cause more friction. Have you ever wondered how small changes can impact your work? Even a tiny adjustment to the lead screw can affect your project’s outcome. Choose wisely for the best results!What is a Lead Screw?

Definition and function in a metal lathe. Importance of lead screws in machining accuracy.A lead screw is a long, threaded rod found in metal lathes. It helps move the tool or workpiece in precise directions. This movement is important for making accurate cuts.

Lead screws improve machining accuracy by:

- Guiding the tool smoothly.

- Ensuring consistent movement.

- Reducing errors during shaping.

Without a lead screw, creating exact shapes would be much harder. It plays a key role in turning raw materials into finished products. Accurate designs help create better parts for machines and other items.

What is the purpose of a lead screw in machining?

The purpose of a lead screw in machining is to enable precise movement. It allows users to accurately control the position of tools and workpieces. This ensures high-quality results in metalworking.

Lead Screw vs. Ball Screw: Key Differences

Comparison of efficiency and precision. Pros and cons of each type for different applications.Lead screws and ball screws are both used to move objects smoothly. They differ in efficiency and precision. Lead screws are often cheaper and easier to make. They can handle heavy loads well but may wear out faster. In contrast, ball screws are more precise and efficient. They use balls to reduce friction, which helps them work better. However, they cost more and can be complex to install.

- Lead Scriew: Good for heavy loads, less accurate, cheaper.

- Ball Screw: More precise, efficient, but more expensive.

How do lead screws and ball screws compare?

Lead screws are strong but less precise, while ball screws offer high precision but at a higher cost.

Factors to Consider When Choosing a Lead Screw

Load capacity and torque requirements. Compatibility with your existing lathe machinery.Choosing a lead screw is important for your metal lathe. First, check the load capacity. This tells you how much weight the screw can handle. Next, consider the torque requirements. This is the force needed to turn the screw. Make sure these match your project needs. Also, check its compatibility with your lathe machine. For smooth operation, parts should fit well together. Always look for the best features that fit your work style!

What are the Load Capacity and Torque Requirements?

Load capacity is how much weight the screw can lift, while torque is the twisting force needed to move it. Make sure these match your task!

Why is Compatibility Important?

Compatibility ensures that the lead screw works well with your lathe. If they fit together, you’ll have smoother results.

Benefits of Upgrading Your Lead Screw

Improvements in machining performance and output. Longterm costeffectiveness and maintenance considerations.Upgrading your lead screw can work wonders for your machining adventure. First off, it can enhance your machining performance. Imagine smoother cuts and better precision! This little upgrade often leads to higher output, making your work easier and faster. Additionally, think of your wallet—good quality lead screws last longer and save you money. Less maintenance means more time crafting masterpieces rather than fixing problems. So, let’s snip those repair costs and keep things spinning smoothly!

| Benefit | Description |

|---|---|

| Improved Performance | Smoother cuts and higher precision |

| Cost-effectiveness | Less maintenance and repair costs |

| Longer Lifespan | Lasts longer than standard lead screws |

Common Problems with Lead Screws

Typical wear and tear issues. Solutions and innovations in lead screw technology.Lead screws can experience typical wear and tear over time. Common issues include thread wear, backlash, and misalignment. These problems can affect the precision of your metal lathe. However, newer technologies are making things better. Innovations in lead screws now provide materials that resist wear. 3D printing is also a game changer, helping to create custom designs. These solutions can help keep your lathe running smoothly.

What are typical problems with lead screws?

Typical problems include wear on threads, backlash, and misalignment. These issues can cause your equipment to function poorly.

Solutions to Help Lead Screws

- Use stronger materials to reduce wear.

- Install adjustment mechanisms to fix misalignment.

- Consider 3D printed parts for unique designs.

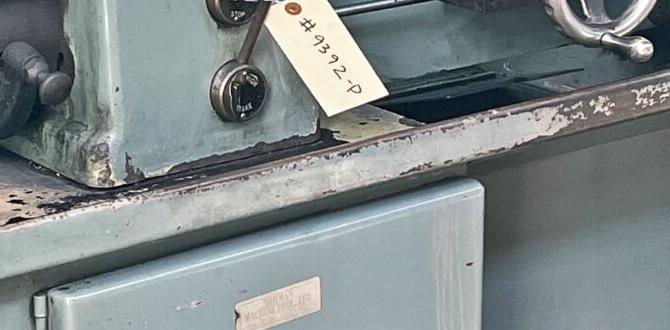

Top Brands and Models of Lead Screws

Analysis of reputable manufacturers and their offerings. Comparative features and price points.Many companies make great lead screws for metal lathes. Some top brands include Grizzly, Jet, and South Bend. Each offers unique features. For example, Grizzly focuses on affordability while still providing quality. Jet has strong precision options, which can be perfect for detailed projects. Then there’s South Bend, famous for its robust designs that last forever! Prices might differ a lot; therefore, customers should explore their choices before buying to ensure they get the best deal for their budget.

| Brand | Key Features | Price Range |

|---|---|---|

| Grizzly | Affordable, reliable | $$ |

| Jet | High precision | $$$ |

| South Bend | Durable, long-lasting | $$$$ |

Installation and Maintenance Tips for Lead Screws

Stepbystep guide to installation. Best practices for maintaining your lead screw.To install your lead screw, follow these steps: First, gather tools like wrenches and a screwdriver. Next, attach the lead screw to the lathe base. Secure it with bolts. Don’t forget to check for correct alignment. Tighten everything well!

For maintenance, keep it clean by removing dust and debris. Lubricate regularly to prevent wear. Also, check for any damage to ensure smooth operation. Here are some best practices:

- Inspect for loose parts monthly.

- Apply grease every few weeks.

- Store securely to avoid rust.

What is the best way to maintain a lead screw?

Regular cleaning and lubrication are key. Checking for damage and keeping it aligned helps it last longer.

User Reviews and Testimonials

Insights from professional machinists. Case studies showcasing different lead screw performance.User reviews give a peek into the world of metal lathes. Professional machinists share their experiences with lead screws, often praising their performance. One noted, “My lead screw is smoother than my cat on a freshly waxed floor!” Insights show that reliable lead screws can improve precision and efficiency in projects.

| Machinist | Lead Screw Performance |

|---|---|

| John D. | Outstanding accuracy in threading. |

| Lisa M. | Great control, like driving a sports car! |

| Mark P. | Durable, still going strong after years. |

Case studies highlight how different lead screws handle tasks. For example, some excel in heavy-duty work while others shine in fine detailing. It’s like comparing a bulldozer to a finely-tuned race car—both have their strengths!

Future Trends in Lead Screw Technology

Innovations on the horizon in lead screw design. Impact of technology advancements on metal lathe performance.New lead screw designs are changing how metal lathes work. These innovations promise better precision and speed. For example, new materials like carbon fiber make lead screws stronger and lighter. This helps in achieving fine details. Technology also helps automate tasks, making machines run smoother and faster. Here are some trends to look out for:

- Smart sensors for real-time monitoring.

- Self-lubricating designs to reduce maintenance.

- Advanced materials for longer life and less weight.

These changes will likely lead to more efficient metal lathes in the future.

What are the main benefits of new lead screw technology?

New lead screws lead to greater accuracy and faster production. They also require less maintenance, which saves time and money.

Conclusion

In summary, a comparison of metal lathe lead screws shows their importance in precision and efficiency. You want a lead screw that fits your lathe’s needs. Pay attention to material, size, and movement. By choosing wisely, you can enhance your projects. We encourage you to explore more about different types and their benefits. Happy machining!FAQs

What Are The Key Differences Between A Lead Screw And A Ball Screw In Metal Lathes, And How Do They Impact Precision And Efficiency?A lead screw uses flat, straight threads to move parts, while a ball screw has little ball bearings that help it roll. Ball screws are smoother and easier to turn, which makes them more precise. This means you can make tighter cuts and get better results. Lead screws are less efficient and can wear out faster. So, if you want to work with high precision and speed, ball screws are often better!

How Does The Design And Material Of A Lead Screw Affect The Overall Performance Of A Metal Lathe?The design and material of a lead screw can change how well a metal lathe works. If the lead screw is strong, it can handle big jobs without bending. A smooth design helps the lathe move better and cut more accurately. Using good materials, like steel, can make the lead screw last longer and work efficiently. So, a good lead screw helps you make better parts!

What Are The Common Failure Modes Of Lead Screws In Metal Lathes, And How Can They Be Mitigated Through Maintenance?Lead screws in metal lathes can have problems like wear and dirt buildup. If they wear out, they can cause wobbling or rough movements. To fix this, we can clean them regularly and add lubrication, which helps them run smoothly. Checking for damage often can also prevent bigger issues. Keeping lead screws in good shape means your lathe will work better for a long time.

How Do The Thread Pitch And Diameter Of A Lead Screw Influence The Speed And Accuracy Of A Metal Lathe’S Movements?The thread pitch is how far the screw moves with one turn. A bigger pitch means it moves faster but less accurately. The diameter is the thickness of the screw. A thicker screw can handle more weight and be more stable, helping with precise movements. So, we need to find the right balance for speed and accuracy.

In Terms Of Cost-Effectiveness And Durability, How Do Lead Screws Compare To Other Types Of Drive Systems Used In Modern Metal Lathes?Lead screws are often cheaper than other drive systems. They work well and last for a long time. You’ll find them in many metal lathe machines. While other systems may be faster, lead screws are reliable and easy to fix. This makes them a smart choice for many people.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences Between A Lead Screw And A Ball Screw In Metal Lathes, And How Do They Impact Precision And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lead screw uses flat, straight threads to move parts, while a ball screw has little ball bearings that help it roll. Ball screws are smoother and easier to turn, which makes them more precise. This means you can make tighter cuts and get better results. Lead screws are less efficient and can wear out faster. So, if you want to work with high precision and speed, ball screws are often better!”}},{“@type”: “Question”,”name”: “How Does The Design And Material Of A Lead Screw Affect The Overall Performance Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design and material of a lead screw can change how well a metal lathe works. If the lead screw is strong, it can handle big jobs without bending. A smooth design helps the lathe move better and cut more accurately. Using good materials, like steel, can make the lead screw last longer and work efficiently. So, a good lead screw helps you make better parts!”}},{“@type”: “Question”,”name”: “What Are The Common Failure Modes Of Lead Screws In Metal Lathes, And How Can They Be Mitigated Through Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws in metal lathes can have problems like wear and dirt buildup. If they wear out, they can cause wobbling or rough movements. To fix this, we can clean them regularly and add lubrication, which helps them run smoothly. Checking for damage often can also prevent bigger issues. Keeping lead screws in good shape means your lathe will work better for a long time.”}},{“@type”: “Question”,”name”: “How Do The Thread Pitch And Diameter Of A Lead Screw Influence The Speed And Accuracy Of A Metal Lathe’S Movements? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The thread pitch is how far the screw moves with one turn. A bigger pitch means it moves faster but less accurately. The diameter is the thickness of the screw. A thicker screw can handle more weight and be more stable, helping with precise movements. So, we need to find the right balance for speed and accuracy.”}},{“@type”: “Question”,”name”: “In Terms Of Cost-Effectiveness And Durability, How Do Lead Screws Compare To Other Types Of Drive Systems Used In Modern Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws are often cheaper than other drive systems. They work well and last for a long time. You’ll find them in many metal lathe machines. While other systems may be faster, lead screws are reliable and easy to fix. This makes them a smart choice for many people.”}}]}