Have you ever wondered how metal parts are shaped and crafted? A metal lathe machine is one of the tools that help turn blocks of metal into precise pieces. Whether it’s for making a simple screw or a complex gear, these machines play a vital role in many industries.

When comparing metal lathe machines, different types and features can surprise you. For instance, did you know that some lathes can make parts with incredible detail in just minutes? While some are small and fit in a garage, others are huge and used in factories.

Imagine building your own projects at home. With the right metal lathe, you could create anything you dream up. So, what should you look for when choosing one? Let’s dive deeper into what makes these machines unique and how they can fit into your world.

Comparison Metal Lathe Machine: Key Features Explained

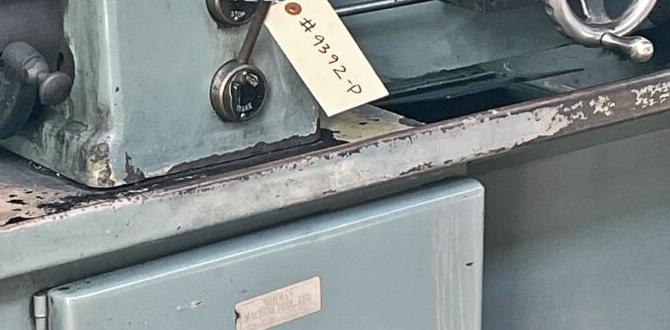

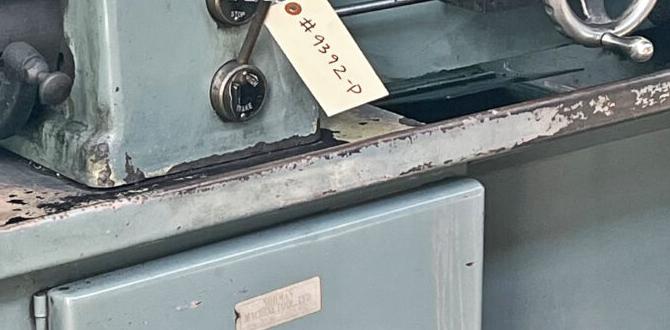

Comparison Metal Lathe Machine

When choosing a metal lathe machine, think about your specific needs. Are you a beginner or an expert? Different machines offer varied features. Some are small and easy to use, while others handle larger projects. Did you know that lathes can create complex shapes from simple metal blocks? It’s fascinating how these machines work magic with metal! Consider factors like speed, size, and cost to find the best fit. Happy machining!Key Features to Consider When Choosing a Metal Lathe

Size and swing capacity. Horsepower and motor specifications. Precision and accuracy levels.Choosing the right metal lathe can feel like looking for a unicorn in a haystack. First, think about size and swing capacity. A bigger swing means you can work with larger pieces. Next, look at horsepower and motor specifications. More horsepower equals more power for tough jobs, like wrestling a stubborn piece of metal. Precision and accuracy are also key. A good lathe keeps things going smoothly, like a magician with a wand. Remember, a well-chosen lathe will make your work easier and more fun!

| Feature | Importance |

|---|---|

| Size | Affects the size of materials you can use |

| Horsepower | Determines power for heavy tasks |

| Precision | Ensures accurate cuts, saving time and materials |

Top Manufacturers of Metal Lathes

Brief profiles of leading metal lathe brands. Comparison of features and technologies offered by each manufacturer.Many brands make metal lathes. Here are a few of the top names:

- Haas Automation: Known for high precision and user-friendly controls.

- Grizzly Industrial: Offers a range of lathes for hobbyists and professionals.

- Jet Tools: Focuses on durability and innovative technology.

- South Bend Lathe: Famous for quality and simplicity.

Each brand has unique features. For example, Haas offers advanced CNC options. Grizzly is great for a variety of budgets. Choosing a lathe depends on your needs and skills.

What should I consider when buying a metal lathe?

You should look for size, precision, and user-friendliness. Different projects need different lathes. Consider what you will create before buying!

Cost Analysis of Metal Lathes

Breakdown of initial investment vs. longterm value. Factors affecting the price: brand, features, and materials.Buying a metal lathe machine can cost a lot, but it’s important to think about the long-term value. First, consider the initial investment. High-quality machines may cost more now, but they often last longer and save money later. Some key factors include:

- Brand: Well-known brands usually have better reliability.

- Features: Extra features often make a machine more useful.

- Materials: Sturdy materials can increase the machine’s lifespan.

In the end, a good metal lathe can be a smart investment. Think carefully to get the best value for your money.

What affects the cost of a metal lathe?

The cost is influenced by the brand, available features, and materials used in the machine. High-quality components typically raise the price.

User Reviews and Testimonials

Summary of user experiences with various metal lathe machines. Common issues and praises found in customer reviews.User experiences with metal lathe machines vary widely. Many customers find the machines reliable and efficient. However, some report issues like wobbling or noisy operations. It’s important to look out for common praises and complaints. For example, users often rave about ease of setup but wish for better customer support. Here’s a brief summary:

| Common Praises | Common Issues |

|---|---|

| Easy to use | Wobbling |

| Great accuracy | Noisy operation |

| Solid construction | Poor customer service |

So, while some users are happily making metal masterpieces, others might need some extra help. Choosing the right machine is like picking a good avocado—don’t rush it!

Comparative Analysis of Popular Metal Lathes

Sidebyside comparison of top models based on specifications. Pros and cons of each model.Choosing the right metal lathe can feel like picking a favorite pizza topping—everyone has their own opinion! To help, we can look at the most popular models. Below is a simple comparison of some top choices, focusing on their key specs, pros, and cons. This way, you won’t be stuck wondering which one is best for your workshop! Let’s take a look.

| Model | Specifications | Pros | Cons |

|---|---|---|---|

| Model A | 10″ swing, 20″ length | Easy to use, compact size | Limited power |

| Model B | 12″ swing, 36″ length | High precision, powerful motor | Heavy and bulky |

| Model C | 8″ swing, CNC | Automated features, great for beginners | Expensive |

So, whether you need power, precision, or portability, there’s a lathe out there just waiting for you—almost like a puppy at a shelter looking for a home!

Applications of Metal Lathe Machines in Different Industries

Exploration of industries that utilize metal lathes: automotive, aerospace, etc.. Specific applications and use cases for various lathe types.Many industries depend on metal lathe machines to shape materials precisely. The automotive sector often uses these machines to create engine components. Think wheels, shafts, and gears! Meanwhile, the aerospace industry relies on lathes to craft lightweight parts that keep planes flying smoothly. From small components like bolts to large pieces like fuselages, lathe applications are vast and fascinating!

| Industry | Applications |

|---|---|

| Automotive | Engine parts, shafts, wheels |

| Aerospace | Fuselages, bolts, lightweight components |

| Manufacturing | Machine tools, fixtures, prototypes |

Maintenance Tips for Longevity

Essential maintenance practices to keep lathe machines in optimal condition. Common problems and troubleshooting techniques.Keeping your lathe machine in good shape is important. Regularly check and clean it to avoid problems. Here are some key tips:

- Lubricate all moving parts.

- Check the belts for wear and tear.

- Look for loose screws or bolts.

- Keep the work area clean.

Common issues might include strange noises or vibrations. If you hear a sound, stop the machine. Tighten anything that seems loose. Regular care helps your machine last longer. Remember, an ounce of prevention is worth a pound of cure!

What are some common lathe machine problems?

Common lathe machine problems include: uneven cuts, wear on the chuck, and motor issues. Regular maintenance helps catch these before they worsen.

Future Trends in Metal Lathe Technology

Emerging technologies impacting metal lathe design and function. Predictions for the future of metal machining and automation.New tools are changing how metal lathes work. Future designs will use smart technology. This means machines may learn and improve on their own. Automation will play a big role. Machines might even work 24/7 without breaks!

- More robots in factories. They help make metal parts quickly.

- Advanced sensors for safety and precision.

- 3D printing combined with lathes for cool designs.

Experts predict that by 2030, 70% of metal machining processes will be automatic. This makes work faster and safer.

What are the emerging technologies in metal lathe design?

Emerging technologies, like AI and robotics, help metal lathes become smarter. They improve speed and accuracy. More companies are using them to stay competitive.

Conclusion

In conclusion, when comparing metal lathe machines, consider factors like size, power, and features. Each machine has strengths for different tasks. Understanding these differences helps you choose the right one for your needs. We encourage you to explore more reviews or visit shops to see them in action. This will help you make a confident decision. Happy machining!FAQs

What Are The Key Differences Between A Cnc Lathe And A Manual Metal Lathe In Terms Of Precision And Ease Of Use?A CNC lathe uses a computer to control the cutting tools. This makes it very precise and gives you consistent results. A manual metal lathe requires you to move the tools by hand, which can be less accurate. Using a CNC lathe is often easier because it does most of the work for you. A manual lathe needs more skill and practice to use well.

How Does The Size And Weight Of A Metal Lathe Machine Impact Its Performance And Suitability For Different Projects?The size and weight of a metal lathe machine matter a lot. A heavy lathe stays in place better while you work. This helps you make accurate pieces. Smaller lathes are easier to move but can handle lighter tasks. For big projects, you might want a heavier, bigger lathe. For small jobs, a lighter, smaller one could be perfect!

What Factors Should Be Considered When Comparing The Horsepower And Torque Ratings Of Various Metal Lathe Machines?When we compare metal lathe machines, we should look at horsepower and torque. Horsepower tells us how fast the machine can work. Torque shows us how much force it has to turn heavy things. A machine with higher torque can handle tougher jobs. So, we need to find a balance between speed and power for our tasks.

How Do The Types Of Materials That Can Be Machined On Different Metal Lathe Models Vary, And What Implications Does This Have For Versatility?Different metal lathe models can work with a variety of materials like steel, aluminum, or plastic. Some lathes are strong enough for hard metals, while others can handle softer materials. This means if you have a more versatile lathe, you can make a wider range of items. For example, with a strong lathe, you can create both tough metal parts and light plastic toys. So, choosing the right lathe helps you make different things for different projects!

What Are The Common Accessories And Tooling Options For Metal Lathes, And How Do They Influence The Machining Capabilities Of Different Models?Common accessories for metal lathes include tool holders, chucks, and tailstocks. Tool holders let you change tools easily. Chucks hold the metal pieces you work on securely. Tailstocks help support longer pieces of metal. These accessories change how the lathe cuts and shapes metal, making some models more useful than others.