Have you ever wondered how metal objects are shaped? Metal lathes are amazing tools that help craftsmen make precise parts. One key part of these lathes is the quill. What is a quill, and why is it so important? Let’s explore that together.

The comparison of metal lathe quills can show us why some are better than others. For example, some quills allow for smoother cutting, while others might not. This difference can change the quality of the metal work. Imagine trying to carve a piece of wood with a dull knife. It’s tough, right? A good quill works like a sharp knife.

Did you know that different types of metal lathes exist for different tasks? Some are used for big projects, while others are for small, detailed jobs. Understanding the comparison between these quills helps you choose the right tool for your project. Ready to dive deeper into the world of lathes and quills? Let’s get started!

Comparison Metal Lathe Quill: Understanding Key Features And Benefits

Comparison of Metal Lathe Quills

Metal lathe quills are important for precision work in machining. They help control the movement of tools while cutting metal. Some quills allow for quick adjustments, making them user-friendly. Did you know that some models provide better stability than others? This can lead to smoother finishes. When selecting a quill, consider factors like size, weight, and features. Finding the right quill can significantly improve your work quality and efficiency.Understanding Metal Lathe Quills

Definition of metal lathe quills. Importance in metalworking and machining applications.Imagine a metal lathe quill as the arm of a robot that helps shape metal. It holds tools and moves them in precise ways. These quills are super important in metalworking. They allow for accuracy and control, making sure every cut is just right. Without them, you’d have a ‘metal mess’ instead of a shiny masterpiece! So, next time you see a lathe, remember that the quill is its trusty sidekick.

| Function | Importance |

|---|---|

| Holds cutting tools | Ensures precision |

| Controls movement | Aids in shaping metal |

| Adjusts depth | Improves quality |

Types of Metal Lathe Quills

Description of fixed quills. Description of adjustable quills. Description of quickchange quills.Metal lathe quills come in different types. First, we have the fixed quill. This type is sturdy and doesn’t move. It’s like a tree that stands tall and firm, perfect for jobs requiring high stability.

Next is the adjustable quill. Imagine stretching like a rubber band! You can change its position easily. This helps in getting the exact depth required for your metal work.

Lastly, there’s the quick-change quill. This one is the superhero of lathe quills! With the ability to swap attachments quickly, it saves time and lets you tackle different tasks effortlessly.

| Type of Quill | Features |

|---|---|

| Fixed Quill | Sturdy, non-movable |

| Adjustable Quill | Flexibility in positioning |

| Quick-Change Quill | Easy attachment swapping |

Key Features to Consider

Material construction and its impact on durability. Size and compatibility with different lathe models. Taper specifications and their relevance.Choosing the right lathe quill matters. First, look at the material. Metal quills are strong and last longer. Next, consider size. Will it fit your lathe? Compatibility is key. Finally, check taper specifications. They connect the quill to the lathe properly. A good fit means better performance.

What features should I look for in a lathe quill?

You should check for durability, size compatibility, and taper specifications. These factors ensure your quill works well with your lathe, allowing for smoother operation.

Performance Comparison

Precision and accuracy in machining. Speed and efficiency in operation. Vibration and stability during use.Machining requires precision, and metal lathes shine here. A good quill offers excellent precision and accuracy, turning raw metal into exquisite shapes. Speed matters too, and efficient operation saves time. Think about it: more time for snacks! Stability is crucial, too. If your machine vibrates like it’s dancing, your work might wobble. That’s not what we want. Here’s a quick look at performance:

| Performance Aspect | Metal Lathe A | Metal Lathe B |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Average |

| Stability | Low Vibration | High Vibration |

Choosing the right quill can make you the machining hero in your workshop. Happy lathe-ing!

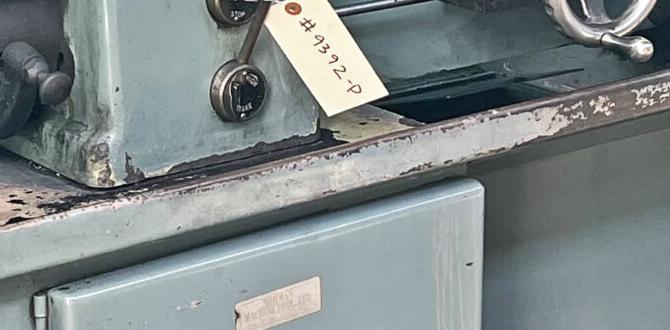

Brand Comparisons

Leading brands in the market. Comparison of product offerings from each brand. Price range and value for money.There are many popular brands that make metal lathes. Each brand has its own special features. Some brands are known for their sturdy machines. Others focus on tricky designs. The prices also vary a lot. Good quality machines can cost more, but they usually last longer. Here are some points to think about:

- Brand A: Offers reliable machines at mid-range prices.

- Brand B: Focuses on advanced features, but they are pricier.

- Brand C: Budget-friendly options that are great for beginners.

Picking the right brand can make a difference. A solid choice can save money in the long run.

What to Look for in Metal Lathe Brands?

Look for quality, price, and features. Consider what you need before choosing a brand. This helps you find the best machine for you.

Maintenance and Care of Metal Lathe Quills

Common issues and troubleshooting tips. Recommended maintenance practices. Lifespan and factors affecting longevity.Taking care of your metal lathe quill is like giving a comfy blanket to your favorite teddy bear. Common issues include wear and tear from overuse or lack of lubrication. To solve this, always check for rust and apply oil regularly. Recommended practices involve cleaning it often and ensuring all parts are snug and secure. On average, a well-maintained quill can last over ten years, but dirt and neglect can cut that lifespan significantly!

| Common Issues | Troubleshooting Tips |

|---|---|

| Rust buildup | Use a rust remover and lubricate |

| Worn bearings | Replace them promptly |

| Loose components | Tighten screws and bolts |

Remember, a happy quill leads to smooth turning. So, treat it well, and it’ll make your projects a breeze! If you ever have doubts, just ask a seasoned machinist for tips—like the wise ones say, “A happy tool is a productive tool!”

User Reviews and Experiences

Summary of user feedback on various quills. Case studies of applications in different industries. Ranking based on user satisfaction.Users have shared a mix of feedback on different quills, and it’s often as colorful as a painter’s palette. Some say that certain quills offer smoother operation, while others appreciate their sturdy construction. In industries like woodworking and metalworking, reviews highlight how these tools perform under pressure—kind of like a superhero in a tight spot!

To give you a better idea, here’s a simple table summarizing user satisfaction:

| Quill Model | User Rating | Industry Application |

|---|---|---|

| Quill A | 4.5/5 | Metalworking |

| Quill B | 4.2/5 | Woodworking |

| Quill C | 4.7/5 | Automotive |

This table shows that many folks are happy, especially with Quill C, which scores high in the automotive world. Overall, user experiences provide a fun, informative peek into what works best!

Choosing the Right Metal Lathe Quill for Your Needs

Factors to consider based on your projects. How to assess your machining requirements. Recommendations for specific applications.Picking the right metal lathe quill can feel like choosing your favorite ice cream flavor—so many options! First, think about your projects. Are you crafting tiny gears or big parts? That’ll change what you need! Assess your machining requirements. What materials will you use? Do you need precision? If you’re making a skateboard, a sturdy quill suits best. For delicate pieces, go for a fine-tuned option. Below is a handy table to guide your choice:

| Application Type | Recommended Quill |

|---|---|

| Tiny Parts | Precision Quill |

| Large Projects | Heavy-Duty Quill |

| General Use | Standard Quill |

So, next time you’re in the shop, remember: the right quill can make all the difference. Happy turning!

Conclusion

In conclusion, comparing metal lathe quills helps you choose the best option for your projects. We learned that different quills offer various features, like adjustability and stability. These factors affect your precision and ease of work. To make the best choice, consider your needs and budget. Explore more resources or tutorials to deepen your understanding of metal lathes.FAQs

Sure! Here Are Five Related Questions On The Topic Of Comparison Of Metal Lathe Quills:Sure! Here are five questions about metal lathe quills. 1. What is a metal lathe quill? A metal lathe quill is a part that holds and moves tools on a metal lathe. 2. How do quills help in shaping metal? Quills help by moving the cutting tool in and out, making it easier to shape metal. 3. Why do some lathes have bigger quills? Bigger quills can hold larger tools, which lets us work on bigger pieces of metal. 4. What materials are quills usually made from? Quills are usually made from strong metal like steel to last longer during use. 5. How can we choose a good quill for our lathe? We choose a good quill by considering its size, strength, and how it fits our tools.

Sure! Please provide the question you’d like me to answer.

What Are The Key Differences Between Fixed And Adjustable Quills In Metal Lathes?Fixed quills stay in one place and can’t be moved. You set them up once, and they don’t change. Adjustable quills can move up and down or side to side. This lets you change how deep or wide you work. So, fixed is for steady work, while adjustable offers more flexibility.

How Does The Material Of The Quill Affect The Performance And Durability Of A Metal Lathe?The quill is a part of the metal lathe that holds the tool. If the quill is made from strong materials, it lasts longer and works better. A durable quill helps keep the tool steady when cutting. This means you get smooth, clean shapes and less chance of breaking. So, the right material can make your work easier and more fun!

In What Situations Would A Shorter Quill Be More Advantageous Than A Longer Quill When Operating A Metal Lathe?A shorter quill is better when you need to work in tight spaces. It gives you more control and precision. If you’re making small parts, a shorter quill can help you avoid mistakes. Using it, you can see your work better and change directions easily.

How Do Quill Designs Impact The Precision And Finishing Quality Of Machined Parts?Quill designs help machines work better. They hold the cutting tool straight and steady. This keeps the cuts precise and clean. If the quill is strong and easy to use, our parts will look nicer. Good quill designs make our finished pieces fit together well.

What Maintenance Practices Are Necessary To Ensure The Longevity And Accuracy Of A Quill On A Metal Lathe?To keep the quill on a metal lathe working well, you should clean it often. Use a soft cloth to remove dirt and metal shavings. Check it for any rust or damage and fix any problems right away. We should also oil the quill regularly to keep it moving smoothly. Lastly, always store the lathe safely to avoid damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Comparison Of Metal Lathe Quills:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about metal lathe quills. 1. What is a metal lathe quill? A metal lathe quill is a part that holds and moves tools on a metal lathe. 2. How do quills help in shaping metal? Quills help by moving the cutting tool in and out, making it easier to shape metal. 3. Why do some lathes have bigger quills? Bigger quills can hold larger tools, which lets us work on bigger pieces of metal. 4. What materials are quills usually made from? Quills are usually made from strong metal like steel to last longer during use. 5. How can we choose a good quill for our lathe? We choose a good quill by considering its size, strength, and how it fits our tools.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Fixed And Adjustable Quills In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Fixed quills stay in one place and can’t be moved. You set them up once, and they don’t change. Adjustable quills can move up and down or side to side. This lets you change how deep or wide you work. So, fixed is for steady work, while adjustable offers more flexibility.”}},{“@type”: “Question”,”name”: “How Does The Material Of The Quill Affect The Performance And Durability Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The quill is a part of the metal lathe that holds the tool. If the quill is made from strong materials, it lasts longer and works better. A durable quill helps keep the tool steady when cutting. This means you get smooth, clean shapes and less chance of breaking. So, the right material can make your work easier and more fun!”}},{“@type”: “Question”,”name”: “In What Situations Would A Shorter Quill Be More Advantageous Than A Longer Quill When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A shorter quill is better when you need to work in tight spaces. It gives you more control and precision. If you’re making small parts, a shorter quill can help you avoid mistakes. Using it, you can see your work better and change directions easily.”}},{“@type”: “Question”,”name”: “How Do Quill Designs Impact The Precision And Finishing Quality Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Quill designs help machines work better. They hold the cutting tool straight and steady. This keeps the cuts precise and clean. If the quill is strong and easy to use, our parts will look nicer. Good quill designs make our finished pieces fit together well.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Necessary To Ensure The Longevity And Accuracy Of A Quill On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the quill on a metal lathe working well, you should clean it often. Use a soft cloth to remove dirt and metal shavings. Check it for any rust or damage and fix any problems right away. We should also oil the quill regularly to keep it moving smoothly. Lastly, always store the lathe safely to avoid damage.”}}]}