Have you ever wondered how metal lathe tools compare? Choosing the right tool can be tricky. With so many options, it’s easy to get confused. Imagine you’re in a store full of shiny tools, but you don’t know which one to pick.

Metal lathe tools are used for shaping and cutting metal. They help makers create everything from parts for machines to beautiful sculptures. Did you know that the first metal lathe dates back to ancient Egypt? That’s over 4,000 years of history!

In this article, we’ll explore the differences between various metal lathe tools. You’ll learn what makes one tool better than another. By the end, you’ll be ready to choose the perfect metal lathe tool for your projects. Let’s dive in and discover the world of metalworking together!

A Comprehensive Comparison Of Metal Lathe Tools

Comparison Metal Lathe Tools

Choosing the right metal lathe tools can feel overwhelming. There are many options available, each with its own strengths. A good starter tool might be a mini lathe, great for small projects. As you gain skills, larger lathes offer more features. Have you ever wondered what tool gives the best finish? The answer often lies in the cutting tools themselves. Explore your options and find the best match for your needs!Key Features to Consider

Size and capacity: swing and length of the bed. Power and motor specifications: horsepower and RPM ratings.Choosing the right metal lathe tool can feel like picking a favorite candy—so many options! First, consider the size and capacity. The swing is the max diameter of workpieces, while the bed length is how long the lathe can handle. Don’t underestimate these—if you plan to create big, chunky items, you’ll need a lathe that can manage the task!

Next up is power and motor specs. Look for horsepower ratings; more horsepower means more strength. Also, pay close attention to RPM ratings, which tell you how fast the lathe spins. Trust me; nobody wants a slowpoke lathe when crafting masterpieces!

| Feature | Description |

|---|---|

| Swing | Maximum diameter of workpieces you can handle |

| Bed Length | Length of the lathe bed for long pieces |

| Horsepower | Indicator of strength to handle tough materials |

| RPM Ratings | Speed of spindle rotation |

Remember, choosing a lathe is like assembling a superhero team—every feature counts!

Material and Build Quality

Comparison of materials used in construction. Importance of rigidity and stability in tool performance.The materials used in metal lathe tools greatly affect their quality and performance. Hard materials like cast iron and steel are common because they offer strength. A stable tool is crucial for accuracy in work. Rigidity prevents vibrations during operation, leading to better results. Here’s a quick look:

- Cast Iron: Good strength and durability.

- Steel: Offers extra toughness and precision.

- Aluminum: Lightweight and easy to handle.

For optimal performance, choose tools that resist bending and provide stability. This ensures a smoother experience while crafting.

What materials are best for metal lathe tools?

Strong materials like cast iron and steel are best. They provide both durability and accuracy, leading to high-quality results.

Your tool’s performance depends on its build quality. Choose wisely!

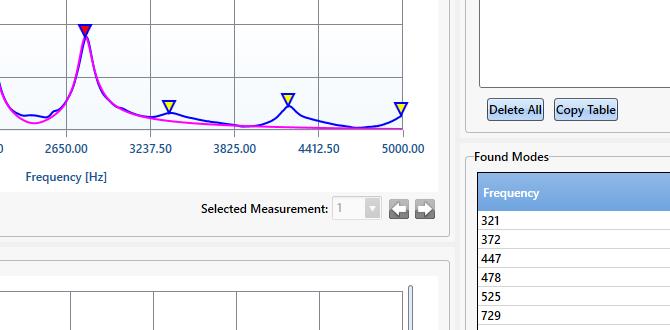

Precision and Accuracy

Measuring tools: DRO (Digital Readout) vs. dial indicators. Tolerances: what to expect and why they matter.Measuring tools play a big role in getting things right. Let’s talk about two of them: DRO (Digital Readout) and dial indicators. DROs show numbers on a screen, making it easy to read measurements. Dial indicators have a needle that points at measurements. Both have their perks, but many people find DROs more user-friendly.

Now, let’s chat about tolerances. Tolerance is the tiny range of error allowed in measurements. It might sound boring, but it’s super important. Imagine building a treehouse that wobbles! You definitely want tight tolerances for stability. Think of it as making sure your pizza has equal slices—no one wants an unfair piece!

| Measuring Tool | Type | Ease of Use |

|---|---|---|

| DRO | Digital | Easy as pie! |

| Dial Indicator | Analog | Requires a bit of practice |

Expect tolerances of about 0.001 inches for high-quality work. Meeting these standards means your projects will look good and work well. So, measure twice, cut once, and always leave room for a laugh while working!

Ease of Use and Learning Curve

User interface: controls and programming of CNC machines. Ergonomics and userfriendly designs in manual lathes.Many users find CNC machines easy to operate. They have a clear user interface with simple controls. This makes programming quick and fun. Manual lathes are also designed with comfort in mind. Ergonomic features help users work without straining their bodies. Both types aim to allow everyone to enjoy machining!

How easy are metal lathe tools to learn?

Learning metal lathe tools can be easy if you start with simple projects. Begin with basic shapes and slowly try more complex designs. Having guidance helps too! Practice builds confidence and skill over time.

Cost Analysis and Budgeting

Price ranges for different types of lathes. Costbenefit analysis for amateur vs. professional use.Buying a lathe can be tricky. Prices vary widely based on type. Here’s a quick look at prices:

- Hobby lathes: $200 to $1,000

- Mid-range lathes: $1,000 to $3,500

- Professional lathes: $3,500 and up

Amateurs often need less expensive models. Professionals may invest more for better quality. Consider if you’ll use it often. Investing in a higher-quality lathe can save money over time. It may last longer and work better.

What should I consider when buying a lathe?

Consider your skill level, budget, and how often you’ll use it. Amateur users may prefer budget-friendly options. Professionals might need advanced features that cost more.

Maintenance and Longevity

Recommended maintenance practices to prolong tool life. Common issues and troubleshooting tips.Taking care of your metal lathe tools makes them last longer. Simple maintenance helps avoid problems. Regular cleaning, oiling, and checking parts keep everything in top shape. Here are some tips:

- Clean after each use.

- Lubricate moving parts often.

- Inspect for worn-out parts regularly.

- Store tools properly to avoid damage.

If you have issues, check for:

- Strange noises while working.

- Poor cutting results.

- Overheating parts.

Addressing these problems early can save time and money. Remember, a well-maintained tool is a happy tool!

How can I ensure my lathe tool lasts longer?

Regular maintenance, cleaning, and proper storage will help your lathe tool last longer.

User Reviews and Community Feedback

Summary of experiences shared by users. Importance of online reviews in decisionmaking.Many users share their adventures with metal lathe tools online. Some praise their durability, saying they feel like superheroes in the workshop! Others mention bumps along the way, like confusing instructions. Online reviews really help because they let you see both sides. It’s like having a friend who has already tried the tool. Before you buy, it’s a good idea to check those reviews. A simple tip? Click the “star rating” filter—it works wonders!

| User Feedback | Rating |

|---|---|

| “Sturdy and easy to use!” | ⭐⭐⭐⭐⭐ |

| “Instructions were confusing.” | ⭐⭐⭐ |

| “Perfect for my hobby!” | ⭐⭐⭐⭐ |

Final Thoughts on Choosing Metal Lathe Tools

Recap of essential considerations for selection. Encouragement to evaluate personal needs and project goals.Choosing the right metal lathe tools is important. Here are some key points to remember:

- Think about your projects and goals.

- Consider your budget.

- Look for tools that match your experience level.

- Check the tool’s durability.

Take time to reflect on what you need. Does your project require precision, or is it more about speed? Knowing this helps in making a good choice. A well-chosen tool can make your work easier and more fun!

What should you consider when selecting metal lathe tools?

Consider your experience, the specifics of your projects, and your budget. These factors help you find the best tools for your needs.

Conclusion

In summary, comparing metal lathe tools helps you choose the best one for your needs. Look for features like durability, size, and ease of use. We recommend checking user reviews for firsthand experiences. Take time to research different brands and models. This way, you can make an informed decision and improve your skills. Happy turning!FAQs

Sure! Here Are Five Questions Related To The Topic Of Comparing Metal Lathe Tools:Sure! Here are five questions about comparing metal lathe tools: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal while cut tools carve it into different shapes. 2. What do you use a lathe tool for? You use a lathe tool to cut, shape, or smooth metal. It helps make parts for machines or other objects. 3. How do we choose a good lathe tool? We choose a good lathe tool by looking at its material, size, and how well it cuts. It should feel comfortable to hold. 4. Why is the tool’s sharpness important? A sharp tool cuts better and faster. If it’s dull, it can break or mess up the shape. 5. Can we use the same tool for different metals? Some tools work on many metals, but others are specific. It’s best to pick a tool meant for the metal you’re using.

Sure! Please provide me with the question you want answered.

What Are The Key Differences Between Cnc Lathes And Manual Lathes In Terms Of Precision And Usability?CNC lathes are computer-controlled machines, which means they can make very precise cuts. This helps us create exact shapes every time. Manual lathes need a person to control them, so they can be less precise. Using a CNC lathe is easier because you just set it up and let it work. With a manual lathe, you need more skill and practice.

How Do Various Types Of Cutting Tools, Such As High-Speed Steel (Hss) Versus Carbide Inserts, Affect The Performance And Longevity Of A Metal Lathe?Different cutting tools can change how well your metal lathe works and how long it lasts. High-speed steel (HSS) tools are good for simple jobs but can wear out faster. Carbide inserts last longer and can cut metal faster. This means you can finish your work quickly and save money on tool replacements. Using the right tool helps your lathe stay strong and work better.

What Factors Should Be Considered When Comparing The Sizes And Capabilities Of Different Metal Lathe Models For Specific Machining Tasks?When we compare metal lathes, we should look at their size first. A larger lathe can handle bigger pieces of metal. Next, we need to check how powerful the lathe is. More power allows us to cut harder materials. Lastly, we should consider the features, like speed options and ease of use. These will make our tasks easier and faster.

How Do Lubrication And Coolant Systems Impact The Efficiency And Quality Of Machining When Using Various Lathe Tools?Lubrication and coolant systems help keep tools and materials cool and running smoothly. They reduce friction, which means tools can work better and last longer. When we use these systems, we get smoother cuts and better quality of the pieces we make. This also means we can work faster and waste less material. So, using the right fluids makes our machining jobs easier and more successful!

What Are The Advantages And Disadvantages Of Different Lathe Accessories, Such As Tool Holders And Chucks, In Enhancing The Functionality Of A Metal Lathe?Lathe accessories, like tool holders and chucks, can make using a metal lathe much easier. Tool holders let you change tools quickly, so you can work faster. However, they can be expensive, which is a downside. Chucks hold the material securely, helping you make better cuts, but they can be heavy and hard to change. Overall, using these accessories can improve your projects, but you should think about the costs and extra weight.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of Comparing Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about comparing metal lathe tools: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal while cut tools carve it into different shapes. 2. What do you use a lathe tool for? You use a lathe tool to cut, shape, or smooth metal. It helps make parts for machines or other objects. 3. How do we choose a good lathe tool? We choose a good lathe tool by looking at its material, size, and how well it cuts. It should feel comfortable to hold. 4. Why is the tool’s sharpness important? A sharp tool cuts better and faster. If it’s dull, it can break or mess up the shape. 5. Can we use the same tool for different metals? Some tools work on many metals, but others are specific. It’s best to pick a tool meant for the metal you’re using.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Cnc Lathes And Manual Lathes In Terms Of Precision And Usability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes are computer-controlled machines, which means they can make very precise cuts. This helps us create exact shapes every time. Manual lathes need a person to control them, so they can be less precise. Using a CNC lathe is easier because you just set it up and let it work. With a manual lathe, you need more skill and practice.”}},{“@type”: “Question”,”name”: “How Do Various Types Of Cutting Tools, Such As High-Speed Steel (Hss) Versus Carbide Inserts, Affect The Performance And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools can change how well your metal lathe works and how long it lasts. High-speed steel (HSS) tools are good for simple jobs but can wear out faster. Carbide inserts last longer and can cut metal faster. This means you can finish your work quickly and save money on tool replacements. Using the right tool helps your lathe stay strong and work better.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Comparing The Sizes And Capabilities Of Different Metal Lathe Models For Specific Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we compare metal lathes, we should look at their size first. A larger lathe can handle bigger pieces of metal. Next, we need to check how powerful the lathe is. More power allows us to cut harder materials. Lastly, we should consider the features, like speed options and ease of use. These will make our tasks easier and faster.”}},{“@type”: “Question”,”name”: “How Do Lubrication And Coolant Systems Impact The Efficiency And Quality Of Machining When Using Various Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubrication and coolant systems help keep tools and materials cool and running smoothly. They reduce friction, which means tools can work better and last longer. When we use these systems, we get smoother cuts and better quality of the pieces we make. This also means we can work faster and waste less material. So, using the right fluids makes our machining jobs easier and more successful!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Different Lathe Accessories, Such As Tool Holders And Chucks, In Enhancing The Functionality Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe accessories, like tool holders and chucks, can make using a metal lathe much easier. Tool holders let you change tools quickly, so you can work faster. However, they can be expensive, which is a downside. Chucks hold the material securely, helping you make better cuts, but they can be heavy and hard to change. Overall, using these accessories can improve your projects, but you should think about the costs and extra weight.”}}]}