Have you ever tried to fix a metal lathe? It’s not always easy. Sometimes, things just don’t work like they should. If you’ve faced strange noises or parts not moving, you’re not alone. Many hobbyists and professionals wonder why this happens.

Imagine you’re in your workshop. You’re excited to start a new project. But then, your metal lathe acts up. It can be frustrating! Understanding how to troubleshoot your lathe can save you time and stress.

Here’s a fun fact: Most lathe problems are simple fixes. You don’t need to be a pro to solve them. This article will help you figure out how to compare different issues and find quick solutions. Are you ready to dive in? Let’s explore the world of metal lathe troubleshooting together!

Comparison Metal Lathe Troubleshooting: Common Issues And Solutions

Comparison Metal Lathe Troubleshooting

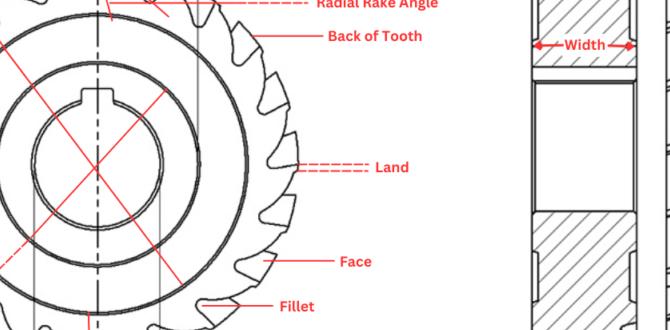

Metal lathes are vital tools for shaping and cutting metal. Yet, they can have issues. Understanding common problems helps fix them quickly. For example, if your lathe makes strange noises, it might need oil in the gears. A wobbly cutting tool can lead to uneven cuts. Learning to identify these problems saves time and frustration. Did you know regular maintenance can extend a lathe’s life? Discovering these tips can make your projects smoother and more enjoyable!Common Issues Faced in Metal Lathing

Identification of prevalent problems such as vibrations, tool wear, and poor finish.. Discussion on how different metals affect lathing outcomes..Many metal lathe users encounter a few annoying problems. Vibrations can turn a smooth operation into a shaky mess. Tool wear happens, making cuts less precise, which can be a real bummer! Then there’s the poor finish—nobody wants their workpiece to look like it was scratched by a bear. Different metals can act differently too. For instance, aluminum is nice and soft, while steel can be tough as nails, leading to unique challenges.

| Common Issues | Effects |

|---|---|

| Vibrations | Causes uneven cuts |

| Tool Wear | Reduces accuracy |

| Poor Finish | Looks bad and unprofessional |

| Metal Type | Affects cutting behavior |

Remember, keeping your lathe in tip-top shape can help reduce these issues during your projects. Happy lathing, and may your metal always shine!

Advanced Troubleshooting Techniques

Techniques for addressing complex issues like alignment and speed settings.. Tools and methods for precision adjustments and measurements..Complex issues can arise with metal lathes, especially with alignment and speed settings. To fix these problems, careful adjustments are key. Use tools like calipers for precise measurements to ensure everything is just right. Don’t forget to check the belts and gears, as these often lead to speed issues.

- Calipers for measuring alignment

- Tachometer for checking speed settings

- Wrenches for tightening components

- Leveling tools for ensuring flat surfaces

These methods can help you get your lathe running smoothly again.

What are advanced techniques for troubleshooting a metal lathe?

Advanced techniques include checking alignment with calipers and adjusting speed settings with a tachometer. Regular maintenance is also important for long-term effectiveness.

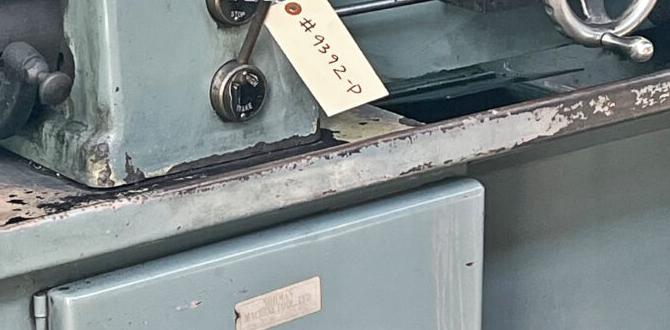

Comparison of Manufacturer Guidelines

Analysis of troubleshooting manuals from leading metal lathe brands.. Understanding the differences in protocols and recommendations..Many popular metal lathe brands provide troubleshooting manuals. These guides can be as different as night and day! Some brands focus on common issues, while others dive into advanced fixes. It’s like comparing apples and oranges, but with more metal shavings. Knowing these differences helps users fix problems faster. Why fumble around in the dark when a clear manual is just a page away? Below is a quick comparison of guidelines from top manufacturers:

| Manufacturer | Focus Area | Recommended Actions |

|---|---|---|

| Brand A | Basic Troubleshooting | Check alignment |

| Brand B | Advanced Repair | Inspect wiring |

| Brand C | Routine Maintenance | Lubricate moving parts |

So, grab that manual next time you encounter a hiccup! Your metal lathe will thank you with smooth cuts.

Troubleshooting Techniques for Specific Metal Types

Tailored approaches for troubleshooting when working with aluminum, steel, and brass.. Impact of metal properties on machine performance and troubleshooting methods..Troubleshooting your metal lathe can feel like trying to teach a cat to swim. Each metal type has its quirks! Aluminum is light, so it needs a gentle touch. Steel is tougher and can be demanding, while brass is a bit sassy, often requiring extra care. Here’s a simple table to help you see how these metals behave:

| Metal Type | Properties | Troubleshooting Tips |

|---|---|---|

| Aluminum | Lightweight, soft | Use high speeds, avoid too much pressure. |

| Steel | Strong, takes heat | Keep tools sharp, adjust feed rate to prevent wear. |

| Brass | Machinable, shiny | Use coolant, take it slow to avoid scratches. |

Remember, each metal can impact your machine’s performance. It’s like playing a game — know the rules, and you won’t be left with a broken lathe and a puzzled look!

Case Studies: Real-World Troubleshooting Scenarios

Detailed examples of troubleshooting in different metal lathing contexts.. Lessons learned and solutions implemented from each case study..In real-life metal lathing, things don’t always go as planned. For example, one shop faced a huge problem: the lathe was making weird noises. After some serious detective work, they discovered a loose belt. Tightening it solved the noise issue! In another case, a worker noticed strange marks on the metal. A quick check revealed the tool was dull. Replacing it fixed the problem. These scenarios show that paying attention helps avoid big headaches!

| Scenario | Issue | Solution |

|---|---|---|

| Noise during operation | Loose belt | Tightened the belt |

| Strange marks on metal | Dull tool | Replaced the tool |

Resources and Tools for Metal Lathe Troubleshooting

List of essential tools, diagnostic equipment, and software.. Suggested websites, forums, and literature for further learning and support..To fix problems with your metal lathe, having the right tools is key. Here are some must-have items:

- Wrenches for tight spots

- Dial indicators for measuring accuracy

- Calipers for checking size

- Lubricants to keep parts running smooth

For deeper learning, visit helpful websites and forums, such as:

- Machinist Forums for sharing tips

- Technical Websites like CNCzone

- Books on lathe mechanics

These resources will guide you through troubleshooting, making your lathe work better.

What tools are needed for troubleshooting a metal lathe?

You need wrenches, dial indicators, calipers, and lubricants to troubleshoot your metal lathe.

Conclusion

In conclusion, troubleshooting a metal lathe involves checking common issues like alignment, speed, and tool sharpness. You can often solve problems by adjusting settings or replacing parts. Don’t hesitate to refer to your lathe manual for specific guidance. Next time you face issues, remember these tips and feel free to explore more resources to enhance your skills!FAQs

What Are Common Signs That Indicate A Metal Lathe Is Misaligned, And How Can These Issues Be Addressed?You can tell a metal lathe is misaligned if your cuts are uneven or wobbly. You might also see extra vibrations when it runs. To fix these issues, you can check the bed and tailstock for straightness. Adjust them carefully until everything lines up right. Regularly checking and cleaning helps keep the lathe working well.

How Does The Choice Of Cutting Tool Materials Affect Troubleshooting On A Metal Lathe?The cutting tool material affects how well the tool cuts metal. Some materials, like high-speed steel (HSS), can be tougher but might wear out quickly. Others, like carbide, last longer but can break if used the wrong way. If your tool isn’t working right, you might need to change materials for better results. Choosing the right material makes it easier to fix problems with your lathe.

What Are Effective Methods For Diagnosing And Fixing Vibration Issues In A Metal Lathe During Operation?To diagnose vibration issues in a metal lathe, you can start by checking for loose parts. Make sure everything is tight and secure. Next, you can look for any worn-out or damaged pieces, like bearings or tool holders. If you still feel vibrations, try adjusting the speed or the way you cut the metal. Finally, balancing the lathe can help reduce shaking during operation.

How Do Different Types Of Lubrication Impact The Performance And Troubleshooting Of Metal Lathes?Different types of lubrication help metal lathes run smoothly. Oils and greases reduce friction, making machines work better. If you use the wrong type, parts can wear out faster. This can cause problems, like strange noises or tool breakage. So, using the right lubrication keeps your lathe happy and working well!

What Preventative Maintenance Practices Can Help Reduce The Frequency Of Troubleshooting For Metal Lathe Problems?To keep a metal lathe working well, we can do some simple things. First, always clean the lathe after using it to remove dirt and dust. Second, check the oil levels and add oil to keep parts moving smoothly. Third, tighten loose parts because they can make problems happen. Finally, look for signs of wear and fix them before they get worse.