Quick Summary:

Proper lathe cutting speed is crucial for clean cuts, tool longevity, and efficient material removal. It’s a balance between spindle speed and workpiece diameter, affected by material, tool type, and desired finish. Get it right, and your lathe work will shine!

Hey there, fellow makers! Daniel Bates from Lathe Hub here. Are you staring at your lathe, wondering if you’re choosing the right speed for that perfect cut? It’s a common puzzle, especially when you’re just starting out. Too fast, and you get a rough finish or burn your tool. Too slow, and you’re barely making a dent, wasting time and potentially stressing your machine. Don’t worry, we’ll break down lathe cutting speed into simple, actionable steps so you can cut with confidence and get amazing results. Let’s get your lathe singing!

Understanding Lathe Cutting Speed: Your First Key to Success

So, what exactly is cutting speed for a lathe? It’s not just about how fast the spindle spins. It’s actually the speed at which the cutting edge of your tool moves across the surface of the workpiece. Think of it like driving a car – you can go slow or fast, and the experience and outcome change dramatically. In machining, cutting speed is usually measured in surface feet per minute (SFPM) or meters per minute (m/min).

Why is this so important? Getting the cutting speed right is like finding the sweet spot. It ensures:

- Clean Cuts: A well-chosen speed helps your tool shear the material cleanly, leaving a smooth finish.

- Tool Longevity: Running at the correct speed prevents your cutting tools from overheating and dulling too quickly.

- Efficient Material Removal: You’ll be able to remove material at a good pace without sacrificing quality or safety.

- Machine Health: Your lathe will thank you for not overworking it.

The goal is to find that magical combination of spindle speed and workpiece diameter that gives you the ideal cutting speed for the material you’re working with and the tool you’re using. It sounds technical, but we’ll simplify it!

The Core Relationship: Cutting Speed, Spindle Speed, and Diameter

The heart of calculating lathe cutting speed lies in a simple formula. It connects three main players:

- Cutting Speed (CS): This is our target – the ideal speed for the tool and material, usually in SFPM or m/min.

- Spindle Speed (SS): This is what you directly control on your lathe, measured in revolutions per minute (RPM).

- Workpiece Diameter (D): The diameter of the material you’re cutting, in inches or millimeters.

Here’s the fundamental formula you’ll use:

Cutting Speed (SFPM) = 0.262 x Diameter (inches) x Spindle Speed (RPM)

And for metric users:

Cutting Speed (m/min) = π x Diameter (mm) x Spindle Speed (RPM) / 1000

Notice how the diameter is in the equation? This is crucial. As the diameter of your workpiece changes (like when you turn a thick bar down to a thin rod), the cutting speed changes even if your spindle RPM stays the same. This is why turning operations often require adjusting your spindle speed as you get closer to your final diameter.

Often, you’ll know your desired cutting speed (from charts or experience) and your workpiece diameter, and you’ll need to calculate the correct spindle speed. You can rearrange the formula:

Spindle Speed (RPM) = Cutting Speed (SFPM) / (0.262 x Diameter (inches))

Or in metric:

Spindle Speed (RPM) = Cutting Speed (m/min) x 1000 / (π x Diameter (mm))

Where to Find Your Target Cutting Speed: Essential Resources

This is where the “proven techniques” really kick in. You don’t have to guess! Reliable machining practices come from established knowledge. Your target cutting speed isn’t pulled out of thin air; it’s determined by the materials you’re working with and the type of cutting tool you’re using.

Material Matters: The Foundation of Your Speed Choice

Different materials have vastly different properties. Softer materials like aluminum or plastics can be cut much faster than harder steels or exotic alloys.

- Soft Metals (e.g., Aluminum, Brass, Plastics): These generally tolerate higher cutting speeds. You can often run your spindle faster.

- Medium Carbon Steels: These require moderate cutting speeds. You’ll need to find a good balance.

- Hardened Steels & Stainless Steels: These demand lower cutting speeds and often require specialized tooling. Heat management is critical.

- Tool Steels: Similar to hardened steels, they need careful speed selection and often slower rates.

Always try to identify your material accurately. Using the wrong cutting speed for a material can quickly ruin your workpiece, dull your tool, or even damage your lathe.

Tooling Factors: The Sharpness and Type of Cutter

The type of cutting tool you use also plays a huge role. High-speed steel (HSS) tools, for example, can’t handle the same speeds as modern carbide inserts.

- High-Speed Steel (HSS): Generally requires slower cutting speeds to prevent overheating and premature wear.

- Carbide Inserts: Can often handle much higher cutting speeds because they are harder and more heat-resistant. However, they can be brittle and may chip if not used correctly.

- Ceramic or CBN Tools: Used for very hard materials and often run at extremely high speeds, but are typically for more advanced applications.

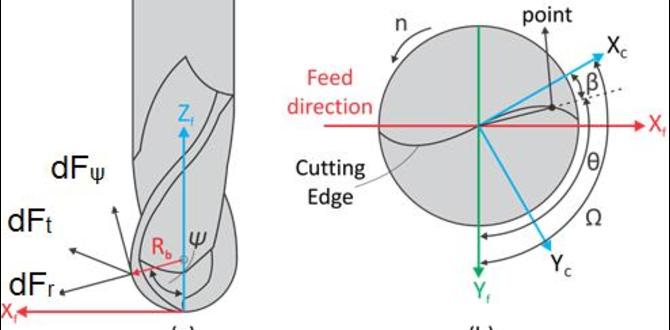

The geometry of the cutting edge (like the rake angle and clearance angle) also affects performance, but for beginners, focusing on material and the basic tool type is a great start.

Practical Steps to Setting Your Lathe Cutting Speed

Now, let’s put it all together. Here’s a common workflow for setting up your lathe for a cut:

Step 1: Identify Your Material and Tool

First, know what you’re cutting. Is it 6061 aluminum? 1018 mild steel? Delrin plastic? Similarly, identify your cutting insert or tool bit. Is it HSS? What shade of carbide (e.g., P10, K10)?

Step 2: Consult a Cutting Speed Chart

This is your best friend as a beginner. Reliable charts provide recommended cutting speeds (SFPM or m/min) for various material/tool combinations. You can find these online, in machining handbooks, or sometimes from tool manufacturers.

Here’s a simplified example chart. Always verify this with a more detailed chart for your specific materials and tools! Industry standards for cutting speeds can be found from organizations like the National Institute of Standards and Technology (NIST), which contributes to manufacturing standards.

| Material Type | Tool Material | HSS Cutting Speed (SFPM) | Carbide Cutting Speed (SFPM) |

|---|---|---|---|

| Aluminum (e.g., 6061) | HSS | 150 – 300 | 300 – 600+ |

| Mild Steel (e.g., 1018) | HSS | 80 – 150 | 250 – 450 |

| Medium Carbon Steel (e.g., 1045) | HSS | 60 – 120 | 200 – 350 |

| Stainless Steel (e.g., 304) | HSS | 40 – 80 | 150 – 250 |

| Cast Iron | HSS | 50 – 100 | 150 – 300 |

Note: These are approximate ranges. Actual speeds can vary significantly based on specific alloy grades, hardness, coating, tool geometry, coolant usage, depth of cut, and feed rate. Always consult a comprehensive chart for your specific situation.

Step 3: Measure Your Workpiece Diameter

You need the current diameter of the piece you’re about to cut. If you’re facing off a new bar, it’s the bar’s diameter. If you’re turning down a section, measure the diameter of that section.

Step 4: Calculate the Required Spindle Speed (RPM)

Using your chosen cutting speed (from the chart) and your workpiece diameter, plug them into the rearranged formula:

Spindle Speed (RPM) = Cutting Speed (SFPM) / (0.262 x Diameter (inches))

Example:

- You’re turning 1045 steel with a carbide insert.

- Your cutting speed chart suggests 250 SFPM for this combination.

- Your workpiece currently measures 1.5 inches in diameter.

Calculation:

Spindle Speed = 250 SFPM / (0.262 x 1.5 inches)

Spindle Speed = 250 / 0.393

Spindle Speed ≈ 636 RPM

So, you’d set your lathe spindle to approximately 636 RPM for this cut.

For metric:

- You’re turning aluminum (6061) with a carbide insert.

- Your cutting speed chart suggests 150 m/min.

- Your workpiece currently measures 40 mm in diameter.

Calculation:

Spindle Speed = 150 m/min x 1000 / (3.14159 x 40 mm)

Spindle Speed = 150000 / 125.66

Spindle Speed ≈ 1194 RPM

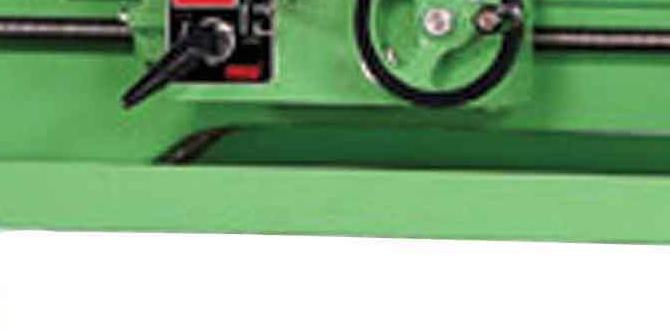

Step 5: Set Your Lathe’s Spindle Speed

Now, adjust your lathe’s speed control (usually a dial or lever system on the headstock) to the calculated RPM. Most lathes have a tachometer or a display to show the current spindle speed. If yours doesn’t, you might have to rely on gear settings and a lookup chart that came with your machine.

Step 6: Make the Cut and Assess

Make a test cut. Listen to the machine. Observe the chips. How do they look? How does the finish on the workpiece look?

- Ideal Chips: Should be ribbon-like, not too long and stringy (can indicate feeds too low or speeds too high), and not granular or powdery (often indicates speeds too low or feeds too high). For metals, they should typically curl nicely.

- Finish: Should be smooth and consistent, without glazing or burning.

- Sound: The lathe should sound smooth and steady, not strained or chattering.

Step 7: Adjust if Necessary

If the cut is too rough, the tool is chattering, or the chips look wrong, you may need to adjust your speed or feed rate. Often, a slight increase orDecrease in RPM can make a big difference.

Remember that the feed rate (how fast the tool advances into the material) is the other half of the cutting equation and works in conjunction with speed. You might need to experiment to find the best combination.

Advanced Considerations & Common Pitfalls for Beginners

While the basic formula is a fantastic starting point, a few more things can influence your success.

Depth of Cut (DOC)

Your choice of cutting speed is also influenced by how much material you’re trying to remove at once (Depth of Cut). Taking a very deep cut requires a slower speed or a more robust tool setup than taking a light finishing pass.

- Heavy Cuts: Tend to generate more heat and stress. You might need to reduce SFPM and often use a lower RPM to compensate, especially if your machine has limited power or rigidity.

- Light Finishing Cuts: Can often be done at higher SFPM, focusing on a good surface finish.

Machining resources like those from The Society of Manufacturing Engineers (SME) delve deep into these parameters, but for beginners, start with moderate depths of cut and adjust as you gain experience.

Coolant and Lubrication

Using cutting fluid or a lubricant is often overlooked by beginners but is vital, especially for harder materials. Coolant doesn’t just cool; it also lubricates the cutting edge and helps clear chips. This allows you to run the tool more efficiently and at potentially higher speeds without damage.

Workpiece Rigidity and Setup

A wobbly workpiece or an improperly supported tool will cause chatter and poor finishes, regardless of your cutting speed. Ensure your workpiece is securely held in the chuck or between centers and that the tool post and tool are rigidly mounted.

Machine Capabilities

Smaller hobby lathes might not have the power or

rigidity to handle the high speeds used on industrial machines. Likewise, older machines may not have precise RPM displays. Always know the limitations of your equipment. A general rule of thumb for hobby lathes is to start on the lower end of the recommended speed ranges.

When to Adjust Your Spindle Speed During a Cut

The most common reason to adjust your spindle speed during a turning operation is as the workpiece diameter shrinks.

Imagine you’re turning a 2-inch diameter bar down to 1 inch. If you set your lathe at the calculated RPM for 2 inches, that same RPM will result in a much higher surface speed (SFPM) when you reach 1 inch. This can lead to overheating, rapid tool wear, and a poor finish on the smaller diameter.

The process should be:

- Calculate RPM for roughing at the starting diameter.

- Perform roughing cuts, adjusting RPM if needed as diameter decreases substantially.

- Measure the diameter frequently.

- For finishing passes at a smaller diameter, recalculate the RPM based on the new, smaller diameter to maintain the ideal SFPM.

This continuous adjustment is what seasoned machinists do implicitly, but for beginners, actively recalculating ensures you’re always in the “sweet spot” for cutting speed.

Lathe Cutting Speed: A Table of Common Scenarios

Let’s look at a few more applied examples to solidify your understanding. We’ll assume you’re targeting a moderate finishing cut with a carbide insert and using a small amount of cutting fluid.

| Operation | Material | Starting Diameter | Target Diameter | Approx. Cutting Speed (SFPM) | Calculated Roughing RPM (for Starting Diameter) | Calculated Finishing RPM (for Target Diameter) | Notes |

|---|---|---|---|---|---|---|---|

| Turning | Aluminum (6061) | 2.0 inches | 1.0 inch | 400 SFPM | 637 RPM (for 2″) | 1273 RPM (for 1″) | Need to increase RPM as diameter reduces. |

| Turning | Mild Steel (1018) | 1.5 inches | 0.75 inches | 300 SFPM | 637 RPM (for 1.5″) | 1273 RPM (for 0.75″) | Adjust RPM as you move from roughing to finishing. |

| Facing | Brass | 3.0 inches | N/A (full face) | 350 SFPM | 376 RPM (for 3″) | N/A | Facing speed is based on the largest diameter being cut. |

This