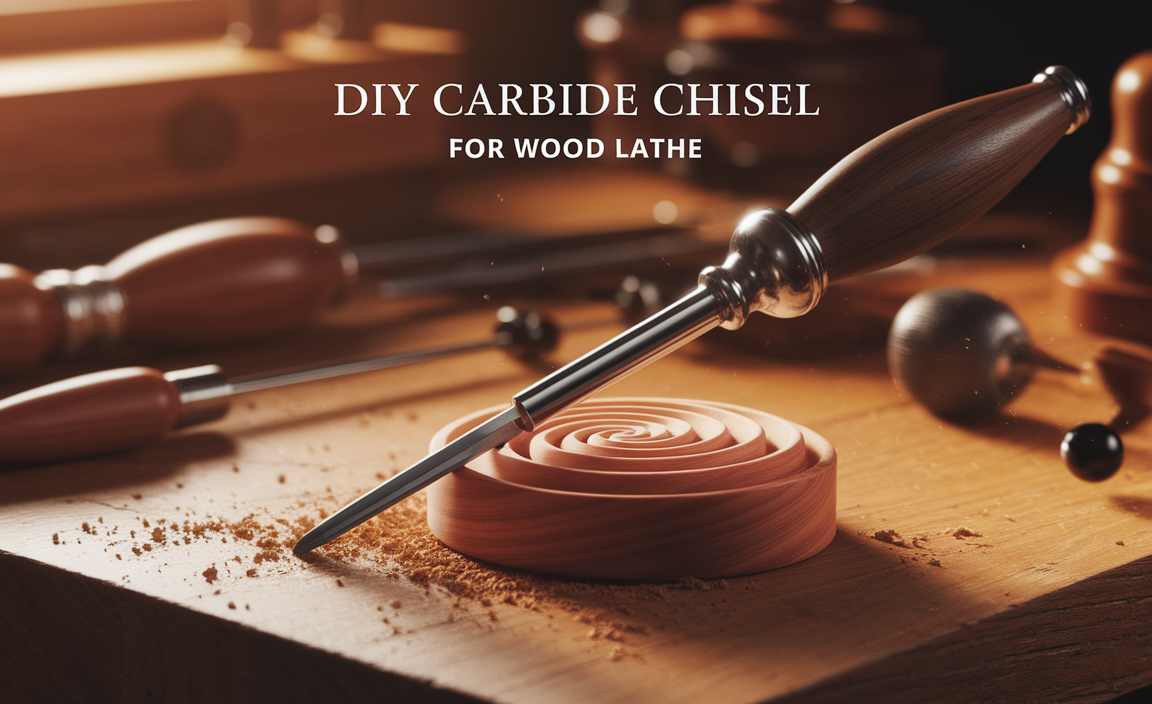

Have you ever watched a wood lathe in action? It’s mesmerizing to see raw wood transform into beautiful shapes. But what if you could make your own tools for this craft? That’s where a DIY carbide chisel comes into play. Making your own chisel can be a fun and rewarding project.

Many woodworkers love a good challenge. Crafting your own carbide chisel means you can customize it to fit your style. Imagine the satisfaction of shaping wood with a tool you created yourself!

Did you know that carbide tips can last much longer than regular steel? They stay sharp for a long time, making your work easier. Discovering how to create a DIY carbide chisel can teach you valuable skills.

Are you ready to dive into this exciting project? With a few simple materials and some patience, you too can make your own carbide chisel for the wood lathe. Let’s explore how to get started on this creative journey!

Diy Carbide Chisel For Wood Lathe: Craft Your Own Tools!

Creating a DIY carbide chisel for your wood lathe can be an exciting project. You can turn simple materials into effective woodworking tools. This process saves money and allows for custom designs. Imagine crafting a chisel tailored just for you! It’s a fun way to learn about tool-making and enhance your lathe skills. Plus, using carbide means longer-lasting sharpness. Are you ready to try building your own chisel? This could change how you work with wood forever!

Understanding Carbide Tools

Explanation of carbide material and its advantages for woodturning.. Comparison with traditional steel chisels in terms of durability and performance..

Carbide tools are like superheroes for woodturning. Made from a special mixture of carbon and tungsten, they are super strong and last longer than traditional steel chisels. Think of them as the “invincible” sidekick in your toolkit! Because they hold their edge better, you spend less time sharpening and more time creating beautiful pieces.

| Feature | Carbide Tools | Steel Chisels |

|---|---|---|

| Durability | Very High | Moderate |

| Frequency of Sharpening | Rarely Needed | Often Required |

| Performance | Outstanding | Good |

With carbide chisels, you can enjoy smoother cuts and better finishes. Remember, the right tool makes all the difference! You wouldn’t use a spoon to cut a steak, right? So, why settle for less with your wood? Grab a carbide chisel, and let your creativity flow!

Step-by-Step Process to Make a DIY Carbide Chisel

Detailed instructions on cutting and shaping the tool holder.. Guidelines for securely attaching the carbide insert to the tool holder.. First, grab a piece of tool steel, about 1 inch wide and 1/4 inch thick. Cut it down to your desired length. A hacksaw works well, but don’t worry if it takes a few swings. Picture yourself as a lumberjack! Next, use a grinder to shape one end into a point; it should look sharp and ready to take on wood. Here’s where the real fun starts: attach the carbide insert. Place it on the end and mark where to drill holes for screws. Drill carefully and secure it with screws. Voilà! You now have a DIY carbide chisel that can take on any wood like a champ!

| Step | Action |

|---|---|

| 1 | Cut tool steel to length |

| 2 | Grind one end to a point |

| 3 | Mark spots for carbide insert |

| 4 | Drill holes and secure |

Design Considerations for Your Chisel

Factors to consider when choosing the chisel shape and size for specific turning tasks.. Importance of ergonomics in the design for comfort and control during use..

Choosing the right chisel shape and size is key for your wood turning jobs. Consider these factors:

- Task Specificity: Different shapes work for different projects.

- Handle Design: Ergonomic handles give comfort and control.

- Blade Size: A larger blade suits big projects, while smaller blades are better for details.

Good ergonomics help prevent strain. A comfortable grip lets you work longer and with more accuracy. Remember, a well-designed chisel can make turning a joy!

What shape should a chisel be for wood turning?

The chisel shape should match the type of work. For curves, use a rounded shape. For straight cuts, a flat edge works best. Choose wisely!

Safety Precautions While Working

Key safety tips to follow when using tools and working with materials.. Importance of personal protective equipment (PPE) during the chiselmaking process..

Using tools can be fun, but safety is very important. Always wear personal protective equipment (PPE) like gloves and goggles. This protects you from flying wood chips and sharp edges. Here are some key safety tips:

- Keep your workspace clean and organized.

- Check your tools for damage before use.

- Always cut away from your body.

- Stay focused and avoid distractions.

Following these safety rules will help you work safely while making your DIY carbide chisel for wood lathe. Remember, safety comes first!

Why is PPE important while making chisels?

PPE is crucial because it protects you from injuries like cuts or eye damage. Using the right gear keeps you safe and lets you enjoy the crafting process. Stay safe, stay smart!

Testing and Fine-tuning Your Chisel

Instructions on how to test the chisel on different wood types.. Tips for adjusting the chisel for optimal performance and sharpening techniques..

Testing your chisel is a fun adventure! Start by trying it on different types of wood. Softwoods, like pine, are usually easier to cut. Hardwoods, like oak, can be tricky, but they help you learn. If the chisel catches, it might need a tweak!

For adjusting, make small changes to your chisel angle. This can help improve the cut. To keep it sharp, use a fine file or a sharpening stone. A sharp chisel is a happy chisel! Remember, a dull chisel is like a grumpy friend—no fun at all!

| Wood Type | Chisel Performance |

|---|---|

| Softwood | Easy to cut |

| Hardwood | More resistance, needs fine-tuning |

So, test, adjust, and make that chisel shine! Happy woodturning!

Common Mistakes to Avoid

List of frequent errors made during the DIY process and how to avoid them.. Tips on maintaining the quality and longevity of your homemade carbide chisel..

Making a DIY carbide chisel can be fun, but some common mistakes can ruin the project. Here are ways to avoid these errors:

- Skipping Measurements: Always measure twice before cutting.

- Using Poor Quality Materials: Invest in good materials for better results.

- Neglecting Safety Gear: Always wear safety glasses and gloves.

- Forgetting to Maintain: Clean your chisel regularly to keep it sharp.

These tips will help keep your chisel working well for a long time. Enjoy your woodturning!

What are the best practices for maintaining a DIY carbide chisel?

To keep your DIY carbide chisel sharp, clean it after every use and store it in a safe place. Regularly check for any damage and sharpen it as needed for the best performance.

Conclusion

In conclusion, making a DIY carbide chisel for your wood lathe can be fun and rewarding. You can save money and customize your tools. With the right materials and steps, you’ll improve your woodturning skills. Start by gathering supplies and following online guides. Don’t hesitate to explore more articles to enhance your woodworking journey!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Diy Carbide Chisels For Wood Lathes:

Sure! Making your own carbide chisels for a wood lathe can be fun. You’ll need some simple tools and materials. Start by getting carbide tips and a sturdy handle. Then, you can attach the tips to the handle. Remember to be safe and ask an adult for help if needed!

Sure! Please provide the question you would like me to answer.

What Materials Are Required To Create A Diy Carbide Chisel For Use On A Wood Lathe?

To make a DIY carbide chisel for a wood lathe, you need a few materials. First, get a sturdy metal rod for the handle. Next, find carbide inserts, which are hard pieces that help cut the wood. You will also need screws to attach the carbide to the handle. Lastly, gather some tools like a drill and a saw to help you put everything together.

What Are The Benefits Of Using Carbide Tips Compared To Traditional Steel Chisels For Woodturning Projects?

Carbide tips are better than steel chisels for a few reasons. First, they stay sharp longer, so you don’t have to sharpen them as often. Second, they cut through wood smoothly, making your work easier. Finally, they can handle tough wood without breaking, which helps you finish your projects faster.

How Can I Properly Shape And Sharpen A Homemade Carbide Chisel To Achieve Optimal Cutting Performance?

To shape your homemade carbide chisel, start by using a diamond file. Rub the file along the cutting edge to make it sharp. You can also use water or oil to help keep it cool. Make sure to keep the angle flat and even while sharpening. Finally, test the chisel on wood to see how well it cuts!

What Safety Precautions Should I Take When Using A Diy Carbide Chisel On A Lathe?

When using a DIY carbide chisel on a lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and remove loose clothes. Make sure your hands are dry and give yourself enough space to work safely. Always use the tool with both hands and keep your fingers away from the spinning part. Lastly, never rush; work slowly and carefully.

Are There Specific Designs Or Modifications To Consider When Making A Carbide Chisel For Different Types Of Woodturning Tasks?

Yes, when making a carbide chisel, you should think about the type of wood you will use. Softer woods need a sharper edge for smooth cuts. Harder woods may need a stronger tip that won’t break easily. The shape of the chisel can also change. A wider tip works well for bigger pieces, while a thinner tip is better for details.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Diy Carbide Chisels For Wood Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Making your own carbide chisels for a wood lathe can be fun. You’ll need some simple tools and materials. Start by getting carbide tips and a sturdy handle. Then, you can attach the tips to the handle. Remember to be safe and ask an adult for help if needed!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Materials Are Required To Create A Diy Carbide Chisel For Use On A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a DIY carbide chisel for a wood lathe, you need a few materials. First, get a sturdy metal rod for the handle. Next, find carbide inserts, which are hard pieces that help cut the wood. You will also need screws to attach the carbide to the handle. Lastly, gather some tools like a drill and a saw to help you put everything together.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using Carbide Tips Compared To Traditional Steel Chisels For Woodturning Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide tips are better than steel chisels for a few reasons. First, they stay sharp longer, so you don’t have to sharpen them as often. Second, they cut through wood smoothly, making your work easier. Finally, they can handle tough wood without breaking, which helps you finish your projects faster.”}},{“@type”: “Question”,”name”: “How Can I Properly Shape And Sharpen A Homemade Carbide Chisel To Achieve Optimal Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To shape your homemade carbide chisel, start by using a diamond file. Rub the file along the cutting edge to make it sharp. You can also use water or oil to help keep it cool. Make sure to keep the angle flat and even while sharpening. Finally, test the chisel on wood to see how well it cuts!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Using A Diy Carbide Chisel On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a DIY carbide chisel on a lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and remove loose clothes. Make sure your hands are dry and give yourself enough space to work safely. Always use the tool with both hands and keep your fingers away from the spinning part. Lastly, never rush; work slowly and carefully.”}},{“@type”: “Question”,”name”: “Are There Specific Designs Or Modifications To Consider When Making A Carbide Chisel For Different Types Of Woodturning Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, when making a carbide chisel, you should think about the type of wood you will use. Softer woods need a sharper edge for smooth cuts. Harder woods may need a stronger tip that won’t break easily. The shape of the chisel can also change. A wider tip works well for bigger pieces, while a thinner tip is better for details.”}}]}