Designing Your Own Diy Metal Lathe Drive System Guide

Building a DIY metal lathe drive system is a fun project for anyone who loves crafting. This system allows you to shape metal into beautiful pieces. You’ll learn about selecting the right motor and drive components to create a powerful and efficient system. Did you know that a simple setup can significantly enhance your lathe’s performance? With some basic tools, you can create a custom system that fits your needs perfectly! How cool is that?

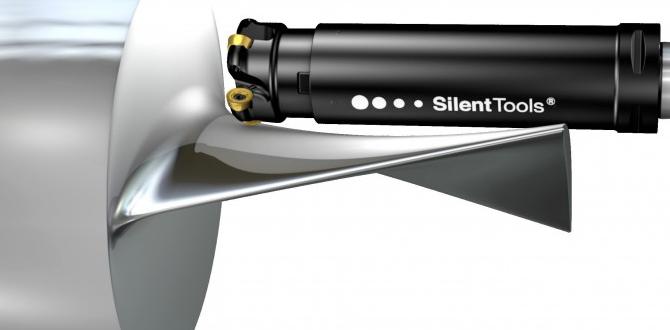

Understanding Metal Lathe Drive Systems

Definition and importance in metalworking. Types of drive systems available.

Metal lathe drive systems are vital in metalworking. They power the lathe, helping shape metal into desired forms. Imagine a superhero for your metal projects! There are several types, each with its own cool features. Some popular types include belt drives, gear drives, and direct drives. Each has its perks, whether smooth operation or high torque.

| Type of Drive | Benefit |

|---|---|

| Belt Drive | Smooth operation |

| Gear Drive | High torque |

| Direct Drive | Quick response |

Choosing the right system can make your projects easier and more fun. Remember, it’s like picking the best ice cream flavor—each option has something special!

Components of a DIY Metal Lathe Drive System

Essential parts required for construction. Recommended materials for durability.

Building a DIY metal lathe drive system is like baking a cake—you need all the right ingredients! Start with essential parts: a motor, pulleys, a belt, and bearings. These pieces work together to help your lathe spin smoothly. For durability, consider using metal or sturdy plastics. They withstand wear better than grandma’s old wooden spoon!

| Component | Recommended Material |

|---|---|

| Motor | Electric Motor |

| Pulleys | Aluminum or Steel |

| Belt | Rubber or V-belt |

| Bearings | Steel |

With these components at hand, you’re ready to make some serious spinning magic. Remember, a well-built system is key to a successful lathe. Let’s get crafting!

Step-by-Step Guide to Building Your Drive System

Tools needed for assembly. Detailed instructions for each component.

Building a drive system can be fun and exciting! You’ll need some simple tools to get started. Grab a wrench, screwdriver, and pliers. Don’t forget safety goggles—protect those peepers!

Follow these steps for a smooth assembly:

| Component | Instructions |

|---|---|

| Motor | Secure the motor to the frame using bolts. |

| Belt | Attach the belt around the motor and pulleys. |

| Controls | Connect the controls, making sure wires are tidy. |

Follow these steps carefully, and soon you’ll have a fantastic drive system! Remember, measure twice and cut once—or you might end up with a fancy paperweight instead!

Motor Selection for Your Metal Lathe Drive System

Types of motors suitable for DIY projects. Power ratings and efficiency considerations.

Choosing the right motor means picking the best buddy for your metal lathe! For DIY projects, you can consider types like brushless DC motors, which are efficient and long-lasting. Another option is the stepper motor, great for precise control but a bit slower. Power ratings should match your project; most lathes work well with motors around 200-300 watts. Efficiency matters, too! An efficient motor saves energy, and your wallet will thank you!

| Motor Type | Power Rating (Watts) | Efficiency |

|---|---|---|

| Brushless DC Motor | 200-300 | High |

| Stepper Motor | 150-250 | Moderate |

Common Challenges and Solutions

Troubleshooting issues during assembly. Frequently encountered problems with DIY setups.

Building a DIY metal lathe drive system can feel like a puzzle, but sometimes, pieces don’t fit right! Common hiccups include misalignment and power issues. Fear not, though! Most problems are easy to fix.

| Problem | Solution |

|---|---|

| Misaligned components | Check measurements and readjust. |

| Poor power supply | Ensure connections are secure and stable. |

| Excess noise | Lubricate parts and check for loose screws. |

With patience and a little humor, you’ll be back to turning metal in no time! Remember, every expert was once a beginner who laughed at their own mistakes.

Safety Considerations When Building Your Drive System

Safety gear and precautions needed. Best practices for working with metal and machinery.

Safety should always come first, especially when working with machines and metal. Wear safety goggles to protect your eyes and ear protection to keep your hearing intact. Don’t forget sturdy gloves to avoid cuts! Keep your workspace clean and dry to prevent slips and falls. It’s smart to follow best practices, like checking your tools before use—nobody likes a surprise malfunction, right? When you feel safe, your creativity can really shine!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect your eyes |

| Ear Protection | Guard against loud noise |

| Sturdy Gloves | Prevent cuts and scrapes |

Upgrading Your Existing Metal Lathe Drive System

Tips on enhancing performance. Compatibility of new components with older machines.

Upgrading your metal lathe drive system can feel like giving your trusty old buddy a shiny new toy! Enhance performance by swapping in a stronger motor or adding better belts. These upgrades can make your machine run smoother than a well-oiled skateboard. Remember, while looking for new parts, check that they fit your older model. Compatibility is key; after all, you wouldn’t want to put on shoes that don’t fit!

| Upgrade Type | Performance Boost | Compatibility Tips |

|---|---|---|

| New Motor | More Power! | Check Voltage Ratings |

| Better Belts | Less Slipping! | Measure Length Carefully |

Cost Analysis of DIY vs. Commercial Solutions

Breakdown of costs associated with DIY projects. Comparison with purchasing premade systems.

Building a DIY metal lathe drive system can save you money. However, consider the costs involved. You might spend on materials like wood, metal, and motors. Tools and assembly can add to the total. Here’s a simple cost breakdown:

- Materials: $100 – $300

- Tools: $50 – $150

- Time invested: 10-30 hours

In contrast, buying a pre-made system ranges from $500 to $2,000. While ready-made tools save time, DIY offers creativity and customization. Which fits your budget better?

What are the benefits of DIY projects?

The benefits include cost savings, personal satisfaction, and the chance to learn new skills. Building something yourself can be very rewarding!

Real-life Examples and Case Studies

Success stories from the DIY community. Innovations and unique designs shared by enthusiasts.

The DIY community is full of creative stories! One enthusiast built a metal lathe drive system from old bicycle parts. It worked better than any expensive model! Another innovator designed a quiet motor system using a recycled fan. This unique twist made their projects super smooth.

| Success Story | Innovation |

|---|---|

| Bicycle Parts Lathe | Using a bicycle to create a metal lathe |

| Quiet Fan Motor | Repurposing fans for a silent drive |

These examples show what is possible with imagination! DIYers are like wizards, turning scrap into treasure. Who knew a bicycle could be the key to craftsmanship? Sharing ideas and designs keeps this community growing strong!

Conclusion

In conclusion, a DIY metal lathe drive system can enhance your projects. You can build one with simple materials and tools. This system helps you achieve more precision and control while working on metal. If you’re interested, check out online guides for step-by-step instructions. Start creating your own drive system, and enjoy the process of making things!

FAQs

What Are The Essential Components Needed To Build A Diy Metal Lathe Drive System?

To build a DIY metal lathe drive system, you need a few important parts. First, get a motor to provide power. Next, you’ll need pulleys to help connect the motor to the lathe. Don’t forget belts to transfer the power from the motor to the lathe. Lastly, make sure you have a sturdy frame to hold everything together.

How Do You Calculate The Appropriate Motor Power And Speed For A Metal Lathe Drive System?

To find the right motor power and speed for a metal lathe, you first need to know the type of metal you’ll cut. Then, check the size of the lathe and the cutting tools. Next, use a simple formula: power equals cutting speed times the force needed. Finally, choose a motor that matches this power and can run at the right speed. This way, your lathe will work well and cut smoothly.

What Types Of Belt Drives Or Gear Systems Are Most Effective For Diy Metal Lathe Applications?

For DIY metal lathes, pulley belt drives work really well. They can change speeds easily when you move the belts. We can also use a gear system with gears of different sizes. This lets you get more power or speed when you need it. Both options help your lathe work better for different tasks.

How Can You Ensure Proper Alignment And Tension In A Homemade Metal Lathe Drive System?

To keep your homemade metal lathe drive system working well, you need to check the parts carefully. Make sure the belt or chain is tight but not too tight. You can use a ruler or a straight edge to see if everything is lined up straight. If the parts are not aligned, they might wear out faster. Always adjust them slowly and test after you make changes.

What Safety Measures Should Be Implemented When Constructing And Operating A Diy Metal Lathe Drive System?

When building and using a DIY metal lathe drive system, we need to be careful. Always wear safety glasses to protect your eyes. Keep long hair tied back and wear snug clothes to avoid getting caught. Use gloves to protect your hands from sharp edges or hot parts. Make sure the area is clean and well-lit, so we can see what we’re doing. Lastly, never work alone; always have someone nearby for help.