Have you ever wanted to create your own tools? Imagine making a DIY metal lathe handwheel. It’s a simple yet rewarding project. With the right materials, you can master your metalworking skills. Are you ready to take on the challenge?

Making a handwheel can be fun and educational. Kids and adults can learn how machines work together. Did you know that a handwheel helps control the speed and precision of a lathe? It makes everything easier! You’ll enjoy the satisfaction of using something you built yourself.

This article will guide you step-by-step. You’ll find tips, tricks, and tools needed for your DIY metal lathe handwheel. So, gather your materials and let’s get started on this exciting journey!

Diy Metal Lathe Handwheel: Create Your Own Precision Tool

Building a DIY metal lathe handwheel can greatly enhance your machining experience. This simple project allows you to create a custom handwheel that fits your specific lathe needs. Using materials like aluminum or steel, you can design a handwheel that improves precision. Did you know that a well-made handwheel can reduce strain and make turning smoother? With basic tools, you can elevate your workshop skills and enjoy the satisfaction of crafting your own equipment.

Understanding Metal Lathe Handwheels

Definition and purpose of handwheels in metal lathes. Various types of handwheels used in metalworking.

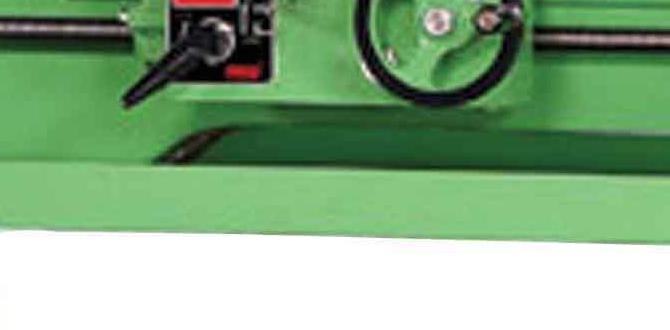

A handwheel is a simple part of a metal lathe that helps you control the machine. Think of it like the steering wheel of a car. You use it to adjust how the lathe moves and shapes the metal. There are different types of handwheels, each with its own special features. Some are large and easy to grip, while others are small and precise. Let’s look at a table to see some popular types:

| Type of Handwheel | Description |

|---|---|

| Standard Handwheel | Commonly used for basic adjustments. |

| Quick-Release Handwheel | Allows fast changes without messing around. |

| Feed Handwheel | Controls the feed speed for smooth cutting. |

Choosing the right one is like picking the perfect snack for movie night—essential for a smooth experience!

Materials Needed for DIY Handwheel

List of essential materials and tools for construction. Recommendations for material quality and durability.

Creating a DIY handwheel is fun and rewarding! To get started, grab a few essential materials and tools. You’ll need metal stock for strength and durability, bearings to help it spin smoothly, and bolts to hold everything together. A good-quality plastic handle can add comfort. Remember, cheap materials might save cash, but they can break faster than a pencil under a heavy book!

| Material/Tool | Recommendation |

|---|---|

| Metal Stock | Medium to high-quality for strength |

| Bearings | Durable for smooth rotation |

| Bolts | Steel to provide sturdy connections |

| Plastic Handle | Comfortable and easy to grip |

Check your local hardware store for these goodies. Happy building!

Step-by-Step Construction Process

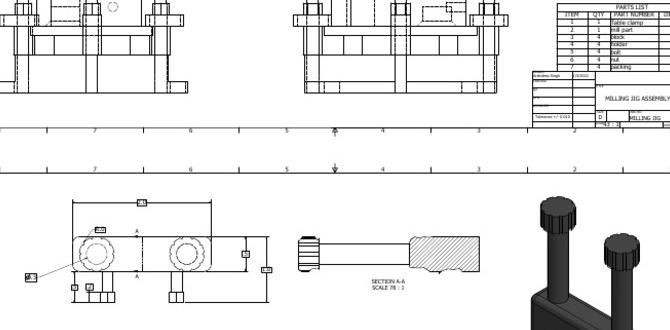

Detailed instructions for measuring and cutting materials. Assembly steps to create a functional handwheel.

Start with measuring your materials. Use a ruler to mark where you’ll cut. Be precise! Next, gather tools like saws and files. Once your pieces are ready, assemble them step by step. Connect the main wheel to the handle. Add any screws or bolts to secure it. Make sure everything turns smoothly. You now have a sturdy handwheel!

How do I assemble the handwheel?

To assemble the handwheel, follow these simple steps:

- Attach the handle to the wheel.

- Secure with screws or bolts.

- Check that it rotates freely.

- Adjust if necessary to ensure smooth operation.

Design Variations and Customizations

Different designs based on user preferences and machine compatibility. Tips for personalizing handwheels with finishes and grips.

Many people want their handwheels to look and feel great. You can personalize your DIY metal lathe handwheel in different ways. Choose designs that match your style and your machine. Some cool ideas include:

- Different shapes: round, square, or even unique styles

- Custom colors: paint it bright or keep it simple

- Special grips: add rubber or foam for better comfort

Making your handwheel unique gives it character. Add a shiny finish or a rough texture. This way, not only does it work well, but it also looks amazing!

How can I personalize my handwheel?

You can personalize your handwheel by changing its shape, color, or grip. Consider adding a fun design or unique texture for an extra touch!

Common Challenges and Solutions

Typical issues faced during DIY handwheel construction. Effective solutions and troubleshooting tips.

Building a handwheel can be tricky. Common problems include uneven surfaces and loose fittings. Here are some easy fixes:

- Check your measurements: Always double-check your sizes before cutting.

- Use proper materials: Select strong materials like metal or durable plastics.

- Secure fittings: Use bolts and screws to keep parts tight.

- Sand surfaces smooth: This helps parts move well together.

If something doesn’t fit, don’t worry! Remake that part and try again. Every mistake is a chance to learn.

What are common mistakes in DIY handwheel projects?

One common mistake is not measuring accurately. Always use precise tools to avoid errors. Another issue is choosing the wrong materials, like weak plastic instead of metal.

Maintenance Tips for Longevity

Best practices for maintaining your DIY handwheel. Signs of wear and when to replace or repair.

To keep your DIY handwheel in great shape, follow a few simple tips. Regularly clean it to remove dust and dirt. Lubricate the moving parts to ensure smooth operation. Check for rust and fix it right away. Watch for signs of wear, like unusual sounds or stiffness. If it feels wobbly or shows cracks, consider replacing it. Your handwheel deserves care!

What are common signs of wear?

Look out for these signs:

- Unusual noises: Grinding or squeaking sounds can signal problems.

- Wobbling: If it shakes while turning, it needs attention.

- Cracks or damage: Any visible breaks should not be ignored.

Benefits of Homemade Handwheels Over Store-Bought Options

Costeffective advantages of DIY handwheels. Quality and customization benefits of creating your own handwheel.

Making your own handwheel can save you money and give you more control. DIY handwheels are often cheaper than store-bought ones. You can use leftover materials to cut costs. Plus, you can design them to fit your needs perfectly. You can choose the size, shape, and color. This way, you create a handwheel that fits your style and projects. Why buy something that might not work well for you?

What are the advantages of making your own handwheel?

Making a DIY handwheel is cost-effective and allows for customization in quality and design.

Reasons to make your own handwheel:

- Lower costs with leftover materials

- Perfect size and shape for your needs

- Unique designs that show your personality

- Better quality using preferred materials

Conclusion

In conclusion, a DIY metal lathe handwheel is useful for precise work. We learned how it enhances control and improves projects. You can create one with simple materials and basic tools. This project is a great way to boost your skills. For more tips and designs, keep reading and explore how you can build your own handwheel today!

FAQs

What Materials Are Best Suited For Constructing A Durable Diy Metal Lathe Handwheel?

For a strong DIY metal lathe handwheel, you can use steel or aluminum. Steel is very tough and lasts a long time. Aluminum is lighter and easier to shape. Both materials can handle a lot of use without breaking. Make sure to choose the one that fits your needs best!

How Can I Accurately Measure And Cut The Metal For My Handwheel To Ensure Smooth Rotation?

To measure metal for your handwheel, use a ruler or tape measure. First, decide how big you want the handwheel. Then, mark the metal where you need to cut. Use a saw to cut along the line carefully. After cutting, check if it spins smoothly; if not, sand the edges a little.

What Design Considerations Should I Keep In Mind When Creating A Handwheel For A Metal Lathe?

When making a handwheel for a metal lathe, you should think about size. It needs to feel comfortable in your hand. The material should be strong, so it won’t break easily. You also want it to turn smoothly and not be too heavy. Lastly, make sure it works with the lathe without any problems.

Are There Any Specific Tools Or Techniques Required For Machining A Metal Lathe Handwheel From Scratch?

Yes, to make a metal lathe handwheel, you need some special tools. You’ll need a lathe, which is a machine that spins metal. You’ll also need a cutting tool to shape the metal. Don’t forget a ruler or caliper for measuring. Safety gear, like goggles, is important too!

How Can I Incorporate Ergonomics Into The Design Of My Diy Handwheel To Enhance Usability?

To make your DIY handwheel easier to use, think about how people will hold it. Make it round or shaped for a comfy grip. Choose a size that fits your hand well, so it’s easy to turn. You can also add soft materials to make it feel nicer when you touch it. Lastly, place it at a height where it’s easy for everyone to reach.