Have you ever watched a metal lathe in action? It’s like magic! Rotating metal spins and transforms into something useful. But did you know that a simple tool called a pulley plays a big role in this process? A DIY metal lathe pulley can be a game-changer for your projects.

Imagine creating your own tools at home. You can save money, learn new skills, and have fun. Building a DIY metal lathe pulley is not just cool; it’s also empowering. It can help improve your lathe’s performance, making it smoother and more efficient.

What if I told you that with the right materials and a little creativity, you can make your own pulley? Many makers have turned to DIY projects to enhance their workshops. You can too! It’s easier than you think, and the results can be quite impressive.

So, are you ready to dive into the world of DIY metal lathe pulleys? Let’s explore tips and ideas that can help you get started!

Diy Metal Lathe Pulley: A Step-By-Step Guide For Beginners

DIY metal lathe pulleys are crucial for creating smooth rotation in machines. They help control speed and torque, making them perfect for hobbyists and professionals alike. Have you ever wondered how a simple pulley can enhance your projects? With the right materials, you can build your own system easily. Learning about pulleys not only boosts your skills but also saves money. Plus, it’s satisfying to create functional tools from scratch. Let’s get started on your journey to DIY success!

Materials Needed for Your DIY Pulley Project

Recommended materials for durability and effectiveness. Tools required for construction and assembly.

Starting your pulley project is exciting! First, gather strong materials for durability. You’ll need metal rods or aluminum for the main body. Don’t forget sturdy bearings, which help everything spin smoothly. For tools, have a saw, wrench, and drill on hand. A friendly tip: keep your workspace tidy, or you might find a missing tool hiding behind that sandwich you forgot from lunch!

| Materials | Tools |

|---|---|

| Metal rods | Saw |

| Aluminum | Wrench |

| Bearings | Drill |

Designing the Perfect Pulley System

Key design principles for optimal performance. Common design mistakes to avoid.

Creating an effective pulley system is like baking a cake: you need the right ingredients and careful planning. Start with strong materials to support weight. Balance is key, so avoid stuffing in too many pulleys—this isn’t a game of tug-of-war! Common mistakes include using mismatched sizes and angles. Check your measurements twice, or you might end up with a “Houdini” pulley that vanishes under pressure!

| Design Principles | Common Mistakes |

|---|---|

| Use strong materials | Mismatched pulley sizes |

| Keep it balanced | Incorrect angle alignment |

| Test the system | Ignoring safety measures |

Remember, a little planning now can save you from a lot of frustration later!

Step-by-Step Guide to Building a Metal Lathe Pulley

Detailed instructions from start to finish. Tips for precision and accuracy in measurements.

Building a metal lathe pulley can be fun! Start by gathering materials and tools like metal rods, a drill, and measuring tape. Measure carefully—bad measurements can lead to a wobbly pulley, and nobody wants a dizzy pulley! Cut the metal to your measurements; precision is key to avoid disasters. Assemble the pieces with care. Need a tip? Always double-check your work, or it might not fit! Here’s a quick view:

| Steps | Tips |

|---|---|

| Gather materials | Choose quality metal |

| Measure and cut | Measure twice, cut once |

| Assemble parts | Use a level surface |

Follow these steps, and you’ll have a pulley that spins smooth as butter!

Installing Your DIY Pulley on a Metal Lathe

Guidelines for safe and effective installation. Common challenges and solutions during installation.

Installing a pulley can be tricky, but safety is key. First, wear protective gear like goggles and gloves. Ensure the lathe is off and unplugged during installation. Common challenges include misalignment and slipping. To fix these, check the alignment carefully and tighten all screws securely. Practice patience! Here are some quick tips for success:

- Measure twice, cut once.

- Use sturdy tools for installation.

- Ask for help if needed.

What are some challenges with pulley installation?

Challenges include misalignment and vibration during operation. Make sure to check all connections and adjust them as needed.

Testing and Adjusting Your Pulley System

Methods for testing performance and stability. How to make necessary adjustments for efficiency.

Are your pulleys wobbling like they’re on a rollercoaster? Time to test and adjust! Bring out your trusty tools. Start by checking for any strange sounds; a clunky pulley is not a happy pulley. Next, use a level to see if everything is even. If not, it’s adjustment time! For better efficiency, align the pulley system properly. Make sure that your belt tension isn’t too loose or too tight. After adjustments, a quick test run helps ensure everything hums smoothly. Remember, a well-tuned system works like magic!

| Test | Description |

|---|---|

| Sound Check | Listen for any unusual noises that could signal problems. |

| Leveling | Use a level to ensure everything is aligned. |

| Alignment | Adjust the pulleys to keep them in line for smooth operation. |

Maintenance Tips for Longevity

Routine maintenance practices to extend pulley life. Signs of wear and how to address them.

To keep your metal lathe pulley working well, regular care is essential. Clean it often to remove dust and dirt. Check for signs of wear, like cracks or unusual noises. These can mean it’s time for repairs. Avoiding problems early helps your pulley last longer.

- Inspect regularly for damage.

- Lubricate moving parts to reduce friction.

- Replace any worn parts quickly.

Doing these simple maintenance steps will help your pulley stay strong and effective.

What are signs of wear on a pulley?

Signs of wear include cracks, strange noises, or problems with movement. If you notice these, check the pulley right away.

FAQs About DIY Metal Lathe Pulleys

Common questions and expert answers. Troubleshooting tips for DIY enthusiasts.

Curious about DIY metal lathe pulleys? You’re in good company! Many folks have questions. Here are some answers to common queries:

| Question | Answer |

|---|---|

| What size pulley do I need? | It depends on your lathe model. Check the manual! |

| How do I install a pulley? | Simple! Just align it with the spindle and secure it tight. |

| What if it squeaks? | Use a bit of oil. Just don’t drown it like it’s a plane in a rainstorm! |

Remember, DIY projects can be tricky. If something doesn’t seem right, don’t fret! Check online forums or ask a friend. They can help you troubleshoot any issues. Happy crafting!

Conclusion

In conclusion, a DIY metal lathe pulley can improve your lathe’s performance. It allows for better speed control and efficiency. You can save money by making it yourself. Remember to gather the right tools and follow instructions carefully. If you’re interested, check out online resources or tutorials to guide you. Take the next step and start crafting your custom pulley today!

FAQs

What Materials Are Best Suited For Making Diy Metal Lathe Pulleys, And Why?

For making DIY metal lathe pulleys, you can use aluminum, steel, or plastic. Aluminum is light and strong, making it easy to work with. Steel is very strong and lasts a long time, but it can be heavy. Plastic is also good and is easier to shape, but it may wear out faster than metal.

How Do I Determine The Correct Size And Ratio For Pulleys In A Metal Lathe Setup?

To find the right size and ratio for pulleys on a metal lathe, you need to measure your lathe first. Check the size of the spindle and the motor. You want the pulley on the motor to be smaller than the one on the spindle. This helps the lathe go faster. Remember, the ratio is the size of the spindle pulley divided by the size of the motor pulley.

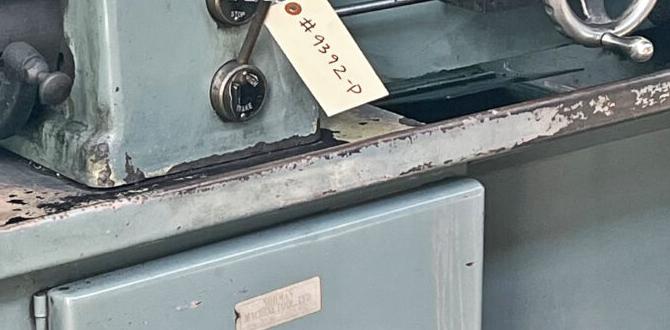

What Tools Are Necessary For Crafting A Custom Metal Lathe Pulley At Home?

To make a custom metal lathe pulley at home, you need a few tools. First, you’ll need a metal lathe. This helps shape the metal. Next, grab a drill to make holes, and a hacksaw to cut metal pieces. Don’t forget safety gear, like goggles and gloves, to protect yourself while you work!

What Common Issues Can Arise When Using A Diy Pulley System On A Metal Lathe, And How Can They Be Addressed?

When you use a DIY pulley system on a metal lathe, some common problems can happen. The pulleys might slip, causing the machine to not work right. You can fix this by checking the tightness of the belts. Sometimes, the pulleys can wobble, making it hard to get a straight cut. To help with this, make sure everything is aligned correctly. Always be careful and wear safety gear while working!

How Can I Achieve Optimal Belt Tension When Installing A Diy Pulley On My Metal Lathe?

To get the right belt tension, start by placing the belt on the pulleys. Next, pull the belt tight but not too tight. You should be able to press the belt down in the middle without much effort. Check if the belt moves smoothly without slipping. Adjust as needed, making sure everything is secure before you test it out!