Yes, you can absolutely build a functional DIY mini wood lathe from an angle grinder! This genius project repurposes common tools to create a surprisingly capable lathe for small woodworking projects, making it an affordable and rewarding build for aspiring woodturners on a budget.

Dreaming of turning small wooden bowls, pens, or decorative pieces but daunted by the cost of a professional wood lathe? You’re not alone! Many aspiring woodturners face this hurdle. The good news is that with a bit of ingenuity and some common tools, you can build your own mini wood lathe. This guide will walk you through a smart DIY approach using an angle grinder, transforming it into a useful machine for your workshop. Get ready to unlock your creativity and start turning!

Why Build a DIY Mini Wood Lathe from an Angle Grinder?

Building a DIY mini wood lathe from an angle grinder is a fantastic project for several reasons, especially for beginners or those with limited space and budget. It’s a testament to creative problem-solving and repurposing tools you might already have.

“It’s not about the fancy machine; it’s about what you can create with your hands and your mind.”

This project offers a unique opportunity to understand the fundamental mechanics of a lathe for a fraction of the cost of a new one. It’s also incredibly satisfying to build a working tool from scratch. You’ll gain valuable hands-on experience that will serve you well as you explore woodworking further. Plus, for small-scale projects like pen blanks, small bowls, or decorative spindles, this DIY lathe can be surprisingly effective.

Benefits of a DIY Angle Grinder Lathe:

- Cost-Effective: Significantly cheaper than buying a new wood lathe.

- Space-Saving: Perfect for small workshops or even a corner of a garage.

- Educational: Provides a hands-on understanding of lathe operation and construction.

- Skill Development: Encourages problem-solving, basic metalworking, and woodworking skills.

- Project Versatility: Suitable for small turning projects like pens, bottle stoppers, and small decorative items.

Safety First: Essential Precautions for Your Build and Use

Before we dive into the build, let’s talk safety. Working with power tools, especially modified ones, demands respect and caution. Always prioritize safety throughout the entire process, from construction to operation.

Think of safety as your most important tool. A well-maintained and safely operated tool is a joy to use; a neglected one can be dangerous.

Always wear appropriate personal protective equipment (PPE). This includes safety glasses or a face shield, hearing protection, sturdy gloves, and a dust mask when sanding or cutting. Ensure your workspace is well-lit and free from clutter. Understand that a DIY lathe, especially one built from an angle grinder, may not have the same safety features as a commercial machine. Therefore, your vigilance is paramount.

Key Safety Gear and Practices:

- Eye Protection: Always wear safety glasses or a full face shield.

- Hearing Protection: Angle grinders can be loud.

- Gloves: Protect your hands from sharp edges and splinters.

- Dust Mask: Essential when dealing with wood dust.

- Secure Work Area: Ensure the lathe is stable and there’s clear space around it.

- Know Your Tool: Understand how your angle grinder and the DIY lathe operate.

- Secure Workpiece: Always ensure your workpiece is firmly attached.

- Never Force the Tool: Let the tool do the work.

For more in-depth safety guidelines on power tools, the Occupational Safety and Health Administration (OSHA) offers comprehensive resources on workshop safety and proper tool usage.

Understanding the Core Components of a Mini Wood Lathe

A basic wood lathe, whether commercial or DIY, has a few key components that work together to spin a workpiece against a cutting tool. Understanding these will help you appreciate the genius of the angle grinder design.

The main parts are:

- Headstock: This holds the motor and the spindle that the workpiece is attached to. In our DIY version, the angle grinder’s spindle will serve this purpose.

- Tailstock: This provides support for the other end of the workpiece and can hold drill bits for drilling into the end of the wood.

- Bed: The sturdy frame that connects the headstock and tailstock and provides a stable base.

- Tool Rest: An adjustable support where you rest your turning tools as you shape the wood.

The beauty of the angle grinder DIY lathe is how it cleverly integrates the angle grinder to act as the headstock and motor. The rest of the components are then fabricated to create the necessary structure and support.

Materials and Tools You’ll Need

Gathering your materials and tools is the exciting part! For this project, we’ll aim for readily available items that can be sourced from hardware stores, scrap yards, or perhaps your existing tool collection.

Materials List:

- Angle Grinder: A corded, variable-speed angle grinder is ideal. The size will depend on the scale of projects you intend to tackle.

- Sturdy Metal Base: Such as a thick steel plate, an old workbench leg, or a sturdy pipe section.

- Wood for the Bed: Two strong pieces of hardwood or thick timber (e.g., 2x4s or 2x6s).

- Metal for Tool Rest Base: A flat metal bar or angle iron.

- Metal for Tailstock: A threaded rod, a bolt, or a short length of pipe that can act as a spindle.

- Wood for Tailstock Body: A block of hardwood.

- Fasteners: Various bolts, nuts, washers, and wood screws.

- Wood for Headstock Mount: A sturdy piece of wood to securely hold the angle grinder.

- Wood for Headstock Spindle Mount: A piece that the angle grinder will attach to.

- Wooden Dowel or Rod:** For the tailstock’s adjustment mechanism.

- Optional: Metal tubing for the tool rest post, a small vise for the tailstock.

Tools List:

- Safety Gear: As mentioned above (eyes, ears, hands, lungs).

- Drill and Drill Bits: For making holes for bolts and screws.

- Wrenches and Socket Set: To tighten bolts and nuts.

- Screwdrivers: For wood screws.

- Saw: For cutting wood (hand saw, circular saw, or miter saw).

- Metal Cutting Tools: Angle grinder (ironically!), hacksaw, or metal-cutting bandsaw for any metal fabrication.

- Measuring Tape and Pencil: For accurate measurements.

- Clamps: To hold pieces together while working.

- Optional: Metal file or grinder for deburring metal edges.

Step-by-Step Build Guide: Creating Your Angle Grinder Lathe

Let’s get building! This guide breaks down the construction into manageable steps. Remember, precision and secure connections are key to a safe and effective lathe.

Step 1: Construct the Base and Bed

The foundation of your lathe needs to be strong and stable.

- Prepare the Base: Select a heavy, flat metal base. This could be a thick steel plate (around 1/4″ or 6mm thick), an old engine block, or a reinforced metal frame. Ensure it’s wide and heavy enough to prevent the lathe from tipping.

- Attach the Bed Rails: Position two parallel lengths of sturdy timber (e.g., 2x4s or 2x6s) on top of your base. These will form the “bed” of your lathe. Ensure they are parallel and securely attached to the base using strong bolts and nuts, or lag screws if your base allows. You want them to be absolutely solid.

- Reinforce if Necessary: If your chosen base isn’t very heavy, consider adding weight to it, like concrete blocks secured to it, to further enhance stability.

Step 2: Mount the Angle Grinder (The Headstock)

This is where the “genius” part of the build really comes into play. We need to securely mount the angle grinder so its disc spins horizontally, creating the lathe’s spindle.

- Create an Angle Grinder Mount: Fabricate a sturdy wooden block or a metal bracket that will firmly hold your angle grinder. This mount should be designed to hold the grinder securely, preventing it from twisting or moving during operation.

- Position the Mount: Place this mount at one end of your lathe bed. The center of the angle grinder’s spindle should be in line with the center of where the workpiece will be. This is crucial for smooth operation.

- Secure the Angle Grinder: Securely fasten the angle grinder into its mount using clamps, bolts, or strong straps. Make sure the grinder’s body is held tightly.

- Angle Grinder Alignment: The angle grinder’s spindle needs to be perfectly horizontal. Use a spirit level to ensure this. Misalignment will cause vibration and poor turning results.

- Power Cord Management: Ensure the power cord has enough slack to move with the grinder if you plan any minor adjustments, but also ensure it won’t get caught or snagged during operation. Drill a hole in the bed or base to route the power cord safely.

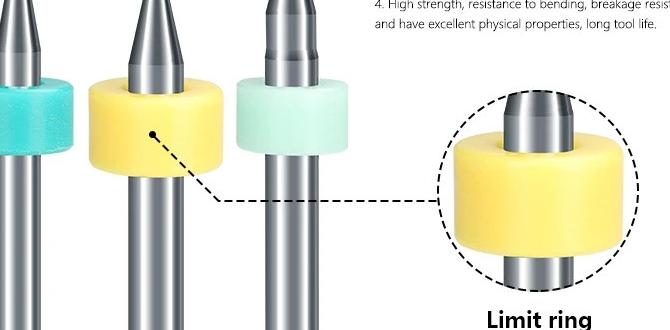

Step 3: Fabricate the Tailstock

The tailstock provides support for the free end of your workpiece. For small turnings, it’s essential for stability.

- Build the Tailstock Body: Take a block of hardwood. You’ll need to drill a hole through its center to accommodate a threaded rod or a bolt that will act as the tailstock spindle. This spindle will push into the end of the workpiece to secure it.

- Create the Spindle Advancement: Attach a handle (like a wooden dowel or a turned knob) to one end of the threaded rod/bolt. This handle will allow you to screw the spindle in and out to engage or disengage the workpiece.

- Mounting the Tailstock Body: Create a base for the tailstock body that can slide along the lathe bed. This could be a piece of wood with a channel that fits over the bed rails or a simple wooden block with holes drilled to accept bolts that clamp it to the bed. The key is portability and secure locking.

- Tailstock Alignment: Ensure the tailstock spindle is perfectly aligned with the angle grinder spindle when locked in place. You can use a ruler or a straight edge. The two spindles must be parallel to each other and at the same height.

- Locking Mechanism: Implement a way to lock the tailstock body firmly in place on the bed. This could be through hand screws tightened against the bed rails or a lever system.

Step 4: Construct the Tool Rest

The tool rest is where you rest your turning chisels. It needs to be adjustable and sturdy.

- Create the Tool Rest Post: Take a piece of metal (e.g., a sturdy rod or a section of angle iron). This will be the vertical part of the tool rest.

- Design the Sliding Mechanism: The tool rest needs to slide along the bed to accommodate different workpiece lengths and be positioned at the correct height relative to the workpiece. You can achieve this by drilling a hole in a wooden block that slides over your bed rails, and then attaching the tool rest post to this block.

- Attach the Rest Surface: At the top of the post, weld, bolt, or screw a flat horizontal surface for your tools to rest on. This can be a piece of flat metal bar or even a smooth, dense hardwood. Ensure this surface is smooth and at the correct height.

- Adjustability: The tool rest post can be made adjustable in height by using slots instead of just holes for bolts, or by incorporating a clamp system that allows the post to be moved up or down.

- Secure Locking: Like the tailstock, the tool rest needs to be securely locked in position on the bed while you are turning.

Step 5: Final Assembly and Testing

With all components fabricated, it’s time to put it all together and run some tests.

- Assemble the Bed, Headstock, and Tailstock: Fix the angle grinder mount securely to one end of the bed. Ensure the tailstock can slide freely along the bed and can be locked in place.

- Attach the Tool Rest: Place the tool rest onto its sliding mechanism on the bed. Ensure it can be moved and locked.

- Mount a Test Piece: Find a simple piece of wood. You’ll need to create a way to mount it. For small pieces, a screw chuck attached to the angle grinder’s spindle (you might need an adapter fitting) or a simple faceplate can work. For longer pieces, you’ll screw one end into the tailstock spindle and use a spur center or chuck on the headstock (angle grinder side). Ensure the workpiece is centered.

- Spindle Alignment Check: Double-check that the angle grinder spindle and the tailstock spindle are perfectly aligned and at the same height.

- Initial Power-Up (No Wood): With the angle grinder unplugged, manually spin the grinder’s spindle to ensure it moves freely. Then, plug it in and turn it on briefly at a low speed (if variable speed) to check for excessive vibration.

- First Wood Test (Low Speed): Secure a small, scrap piece of wood between the headstock and tailstock. Start the grinder at its lowest speed setting. Listen for unusual noises and watch for excessive wobble or vibration. Slowly increase speed as you gain confidence.

Using Your DIY Mini Lathe: Tips for Success

Now for the fun part – turning! Using your DIY lathe requires a slightly different approach than a commercial one. Your focus should be on control and understanding the limitations of the machine.

“The magic is in the process. Take your time, feel the wood, and let the tool guide you.”

Attaching Your Workpiece:

- Faceplate/Screw Chuck: For face-on turning (like small bowls or disks), you can attach a faceplate to your angle grinder’s spindle (you might need an adapter). Then, screw your wood onto the faceplate. Alternatively, a screw chuck offers a simpler solution for initial tests. Remember to ensure these are TIGHTLY secured.

- Live Center/Spur Drive: For spindle turning (like pens or table legs), you’ll need a spur drive center on the headstock side (mounted in a chuck or adapter for your angle grinder) and a live center on the tailstock side to support the other end of the wood.

Turning Techniques:

- Use Appropriate Tools: For a DIY lathe, smaller, sharper turning tools are best. Scrapers and small gouges can be very effective. Avoid long-handled chisels that could catch and cause kickback until you are very confident.

- Rest Your Tools on the Tool Rest: Always keep your tools in firm contact with the tool rest. This provides stability and control.

- Cut Away from Yourself: Always position your tools so that the cutting edge is moving away from you.

- Start Slow: Begin with the lowest speed setting on your angle grinder. As you gain experience, you can gradually increase the speed. Listen to the tool and the wood.

- Light, Consistent Cuts: Take shallow, consistent passes. Don’t try to remove too much material at once. This reduces strain on the grinder and prevents tear-out.

- Watch for Vibration: Excessive vibration is a warning sign. It could mean an unbalanced workpiece, loose mounting, or misalignment. Stop the grinder and investigate.

- Tailstock Support: For longer pieces, ensure the tailstock is firmly engaged. As you turn, the wood can become unbalanced, and the tailstock is crucial for stability.