DIY Small Wood Lathe Projects: Genius & Essential

Get started with your small wood lathe by tackling these genius and essential DIY projects. Perfect for beginners, these projects help you master basic turning techniques, create useful items, and build confidence in your woodworking skills. Learn simple, achievable projects that showcase the power of your lathe.

Welcome to Lathe Hub! If you’ve just unwrapped your shiny new small wood lathe or perhaps dusted off an older one with the goal of diving into some fun projects, you’re in the right place. Many beginners feel a bit overwhelmed at first. You have this amazing tool, but what can you actually make with it? You might be thinking about creating beautiful bowls or intricate spindles, but there are some fantastic, foundational projects that are absolutely essential for learning the ropes. These aren’t just practice pieces; they’re genuinely useful items that will make you feel proud of what you can do. We’ll walk through some of the most rewarding and practical DIY small wood lathe projects designed specifically for those just starting out. Get ready to turn some wood into something wonderful!

Why Start with Small Wood Lathe Projects?

Starting with smaller, simpler projects is a smart move for anyone new to woodturning. It’s all about building a solid foundation and gaining confidence. Think of it like learning to ride a bike; you don’t start by trying to race down a mountain! Small projects allow you to focus on mastering fundamental techniques without the pressure of a large, intricate piece. You’ll learn how to safely use your tools, understand wood grain, achieve consistent shapes, and practice finishing techniques. Plus, the satisfaction of completing a useful item quickly is a huge motivator. These projects are “genius” because they teach you the most without risking frustration. They are “essential” because they build the core skills you’ll need for any future, more ambitious turnings.

Essential Tools and Safety First!

Before we jump into projects, let’s make sure you’re set up for success and, most importantly, safety. Your small wood lathe is a powerful tool, and using it correctly is paramount.

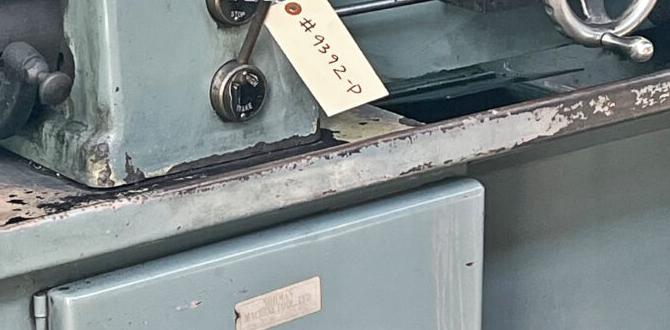

Basic Lathe Setup

Lathe: Ensure your lathe is on a stable, level surface. For smaller lathes, a sturdy workbench is usually sufficient.

Power: Plug it into a properly grounded outlet.

Faceplate/Drive Center: Know how to securely attach these to your lathe to hold your wood.

Tailstock: Understand its function for supporting longer pieces and drilling.

Must-Have Turning Tools (for Beginners)

For most of these initial projects, you won’t need a huge arsenal of tools. A basic set will get you going:

Gouge: A spindle gouge is versatile for shaping and hollowing.

Scraper: A round nose scraper is great for smoothing curves and flattening surfaces.

Parting Tool: Essential for cutting grooves and separating pieces.

Hollowing Tool (Optional but Recommended): Makes creating bowls and hollow forms much easier and safer.

Personal Protective Equipment (PPE)

This is non-negotiable. Always wear your PPE.

Safety Glasses/Face Shield: Protects your eyes from flying wood chips and dust. A full face shield is highly recommended.

Dust Mask/Respirator: Wood dust can be harmful to your lungs over time.

Hearing Protection: Lathes can be noisy.

No Loose Clothing, Jewelry, or Gloves: These can get caught in the lathe’s moving parts. Tie back long hair.

Safe Woodturning Practices

Read Your Lathe Manual: Every lathe is a bit different. Know its specific features and safety warnings.

Secure Your Wood: Ensure your workpiece is firmly attached to the lathe. Use the proper hardware and techniques.

Tool Rest Placement: Position the tool rest close to the workpiece (about pencil-eraser distance) and slightly below the center line for rough turning. Adjust as needed for different operations.

Tool Angle: Learn the correct angles for your tools. Generally, you want to shear cut rather than push straight in.

Speed Control: Start slow, especially with unbalanced or rough stock. Increase speed as the piece becomes more round and balanced. Consult your lathe’s manual for recommended speed ranges based on wood diameter.

Take Light Cuts: Don’t try to remove too much material at once. Multiple light passes are safer and produce better results.

Keep the Area Clean: A clean workspace reduces fire hazards and tripping risks.

For more in-depth safety information, the Woodturners Guild of Ontario offers a comprehensive safety guide for woodturners.

Genius DIY Small Wood Lathe Projects for Beginners

These projects are designed to teach you essential skills while producing items you can actually use or gift.

Project 1: Simple Wooden Pens

Pens are a fantastic first project because they require very little wood and allow you to practice turning, drilling, and the critical step of fitting a pre-made kit.

Skills Learned: Spindle turning basics, drilling accurately, sanding and finishing small pieces, fitting hardware.

Why it’s Genius: Very enjoyable, quick to complete, great for gifts, teaches precision.

Materials Needed:

Pen kit (available online or at craft stores)

Wood blank (hardwood scraps are perfect; about 3 x 3 inches blank)

Drill bits (sized for your pen kit)

Wood glue

Sandpaper (various grits, e.g., 120, 220, 320, 400)

Finishing polish (e.g., CA glue, friction polish)

Basic Steps:

1. Prepare the Wood: Cut your wood blank slightly longer than the brass tubes in your pen kit.

2. Drill the Tubes: Carefully drill out the center of the wood blank using the correct drill bit size to accommodate the pen tubes. Ensure you drill straight!

3. Glue the Tubes: Apply wood glue inside the drilled holes and insert the brass tubes. Let them dry completely.

4. Mount the Blank: Mount the glued blank between centers on your lathe. You might need to use a spur drive and a live center or a chuck.

5. Turn the Blank: Using your gouge and scraper, turn the wood down to the shape of the pen barrel. Aim for symmetrical halves.

6. Sand and Finish: Once turned, sand the wood smooth through progressively finer grits. Apply your chosen finish for a durable and attractive shine.

7. Assemble: Follow the instructions that came with your pen kit to assemble the components.

Project 2: Wooden Pencil Enhancers (or Mini Pencils)

Similar to pens but even simpler, these are basically small wooden sleeves that can hold a standard pencil or be turned into tiny pencils themselves.

Skills Learned: Basic spindle turning, precise diameter control, sanding, finishing.

Why it’s Genius: Extremely simple, uses tiny wood scraps, produces functional desk items.

Materials Needed:

Small wood scraps (e.g., 1 x 1 inch sections)

Drill bit (sized to snugly fit a pencil or a small pencil insert)

Wood glue (if adding an insert)

Sandpaper

Wood finish

Basic Steps:

1. Prepare Wood: Cut small sections of wood to your desired length for the pencil enhancer.

2. Drill Hole: Drill a straight hole through the center of the wood.

3. Mount on Lathe: Mount the drilled wood between centers (use a drive center and tailstock center).

4. Turn Shape: Turn the outside of the wood to your desired shape – cylindrical, slightly tapered, or with decorative bands.

5. Sand and Finish: Sand smooth and apply a finish.

6. Insert Pencil: Push a standard pencil into the hole or glue in a pre-made pencil insert if you’re making a mini pencil from scratch.

Project 3: Simple Tool Handles

Replacing a worn-out handle or making custom handles for small tools like awls, screwdrivers, or even your turning tools is a practical and rewarding project.

Skills Learned: Spindle turning, shaping for ergonomics, drilling for hardware, fitting.

Why it’s Genius: Practical, improves existing tools, allows for custom comfort.

Materials Needed:

Wood blanks (hardwood scraps are ideal)

Drill bit (for the tool shank)

Measuring tape

Sandpaper and finish

Basic Steps:

1. Measure Tool: Measure the diameter and depth of the hole needed for your tool shank.

2. Prepare Blank: Cut a wood blank to the desired length and diameter.

3. Drill Hole: Drill a pilot hole for the tool shank. You may need to enlarge it slightly to get a snug fit or apply glue.

4. Mount on Lathe: Mount the blank between centers.

5. Turn Handle: Turn the blank to a comfortable, ergonomic shape. Consider finger rests or a thicker grip.

6. Sand and Finish: Sand thoroughly and apply a durable finish (e.g., oil, polyurethane).

7. Fit Tool: Once the finish is dry, carefully fit the tool shank into the handle. You might need a light tap with a mallet.

Project 4: Small Tapered Bowls or Dishes

Turning a simple bowl or dish is often a benchmark project for woodturners. Starting with a small, gently tapered shape is much more manageable than a deep, complex bowl.

Skills Learned: Faceplate or chuck turning, roughing, hollowing, external shaping, sanding curves, finishing.

Why it’s Genius: Creates beautiful, functional items from single pieces of wood, teaches fundamental bowl-turning principles.

Materials Needed:

Wood blank (a small round blank, 4-6 inches in diameter)

Faceplate and screws, OR a chuck with jaws.

Bowl gouge or hollowing tool

Scrapers

Sandpaper

Wood finish

Basic Steps:

1. Mount Blank: Attach your wood blank to a faceplate or your chuck. For a faceplate, mark out circles for screw placement and drill pilot holes in the blank’s back.

2. Rough Shape: Turn the outside of the blank to a basic cylindrical or slightly tapered shape. Ensure the base is flat if using a faceplate for later mounting. Let some waste wood remain on the back if you plan to reverse it and hollow.

3. Hollow the Bowl: If using a faceplate, you might leave the back intact or re-mount if needed. If using a chuck, you’ll likely need to turn a tenon on front for the chuck jaws or use screw jaws. Start hollowing from the center outwards using your bowl gouge or hollowing tool. Maintain a gentle, even curve.

4. Shape Exterior Foot: Turn the outside to a pleasing shape, creating a base or foot.

5. Sand: This is crucial for bowls. Sand the interior and exterior thoroughly with progressively finer grits.

6. Finish: Apply a food-safe finish if intended for serving food or a general wood finish.

For safety and technique, resources like the Wood Magazine have helpful articles on basic turning techniques.

Project 5: Wooden Salt and Pepper Grinders

Turned salt and pepper grinders are very popular and look fantastic. You’ll need a grinder mechanism kit, making this similar in complexity to the pens.

Skills Learned: Spindle turning, drilling, fitting hardware, understanding internal mechanics for fitting.

Why it’s Genius: Highly functional, attractive kitchen decor, great gift potential.

Materials Needed:

Salt and pepper grinder kit (includes mechanism and often hardware)

Wood blanks (hardwood is best for durability, e.g., maple, cherry, walnut)

Drill bits

Wood glue

Sandpaper

Wood finish

Basic Steps:

1. Prepare Blank: Cut wood blanks longer than the grinder kit’s body tubes.

2. Drill Holes: Drill out the center of each blank to fit the grinder body tubes snugly. Pay close attention to drilling straight.

3. Glue Tubes: Glue the grinder tubes into the wood blanks. Let them dry completely.

4. Mount on Lathe: Mount the glued blanks between centers. You’ll likely turn two separate pieces – one for the salt grinder and one for the pepper grinder.

5. Turn Body: Turn the wood to your desired shape. Common designs include classic cylinders, tapered shapes, or something more ornate. Ensure consistent diameters for mating parts if they screw together.

6. Sand and Finish: Sand through grits and apply a durable finish.

7. Assemble: Insert the grinder mechanisms according to the kit’s instructions.

Project 6: Simple Lidded Boxes

A small, simple lidded box is a rewarding project that introduces you to turning two separate pieces that need to fit together accurately.

Skills Learned: Spindle turning, faceplate/chuck turning (for the lid), precise fitting, drilling.

Why it’s Genius: Teaches fitting and alignment, creates a keepsake item.

Materials Needed:

Two matching wood blanks (for the box body and lid)

Faceplate or chuck

Drill bit (for the recess/tenon fitting)

Gouge, scraper

Sandpaper and finish

Basic Steps:

1. Prepare Blanks: Cut two blanks to your desired box size.

2. Turn Box Body: Mount one blank on the lathe (initially between centers, then potentially on a faceplate with a recess for the lid). Turn the outside and hollow out the inside slightly, creating a lip or recess where the lid will fit.

3. Turn Lid: Mount the second blank. You can use a faceplate, chuck, or even mount it between centers and turn a tenon that fits precisely into the recess you created on the box body. Turn the top of the lid to its final shape.

4. Refine Fit: Carefully ensure the lid fits snugly and smoothly onto the box body. This often involves slight adjustments.

5. Sand and Finish: Sand both pieces thoroughly and apply a finish. Often, you’ll finish the lid and body separately before the final fit.

6. Final Assembly: Join the lid and body.

Project Suitability for Different Skill Levels

Here’s a quick rundown of how these projects align with your learning journey.

| Project | Key Skills Developed | Complexity Level (Beginner Focus) | Time to Complete (Estimate) |

|---|---|---|---|

| Simple Wooden Pens | Spindle turning, drilling, fitting kits | ★★☆☆☆ (Easy) | 1-3 hours |

| Wooden Pencil Enhancers | Basic spindle turning, drilling small holes | ★☆☆☆☆ (Very Easy) | 30-60 minutes |

| Simple Tool Handles | Spindle turning, ergonomic shaping, drilling | ★★☆☆☆ (Easy) | 1-2 hours |

| Small Tapered Bowls/Dishes | Faceplate/chuck turning, initial hollowing, exterior shaping | ★★★☆☆ (Beginner-Intermediate) | 2-5 hours |

| Wooden Salt/Pepper Grinders | Spindle turning, drilling, fitting kits, symmetry | ★★★☆☆ (Beginner-Intermediate) | 2-4 hours |

| Simple Lidded Boxes | Spindle turning, fitting, precise alignment, multiple pieces | ★★★☆☆ (Beginner-Intermediate) | 3-6 hours |

Tips for Success with Your First Projects

Start with Softwood: For initial practice