Have you ever wondered how to keep your wood lathe in great shape? Regular maintenance is the key to keeping your machine running smoothly. Just like a car needs oil changes, your wood lathe needs care too. Ignoring it can lead to poor performance or even accidents.

Picture this: You’re excitedly working on a new project, and suddenly your lathe starts making strange noises. Frustrating, right? A simple DIY wood lathe maintenance schedule can prevent that. By following a few easy steps, you can enjoy a reliable tool for many years.

Did you know that a well-maintained lathe can improve the quality of your projects? Little adjustments can make a big difference. So, let’s dive into how you can set up a DIY wood lathe maintenance schedule that works for you!

Essential Diy Wood Lathe Maintenance Schedule Guide

DIY Wood Lathe Maintenance Schedule

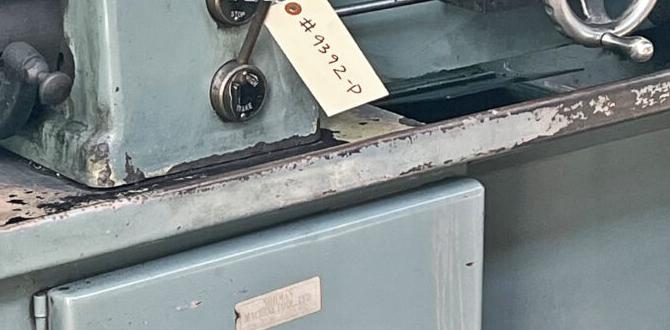

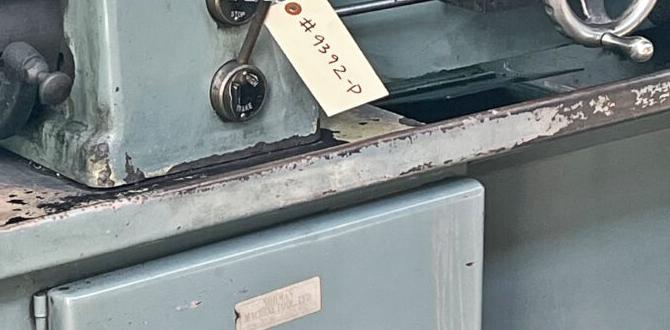

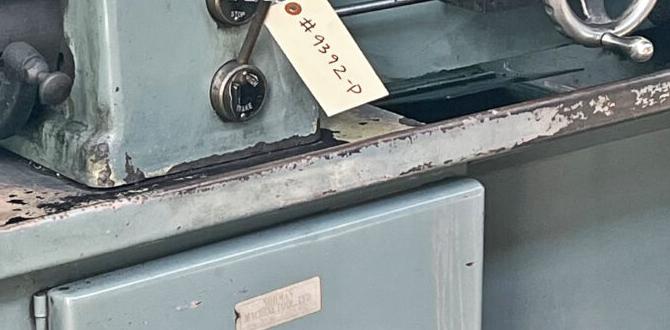

To keep your DIY wood lathe running smoothly, a maintenance schedule is essential. Regularly check bearings, clean the bed, and lubricate parts to prevent wear. Did you know that a well-maintained lathe can last for decades? Schedule inspections every few months to boost performance. You can even create a checklist to make maintenance easier. Remember, a little effort now saves big repairs later. Your projects will thank you for it!Understanding the Importance of Maintenance

Significance of regular maintenance for longevity and performance.. Common issues arising from neglecting maintenance..Maintaining your tools keeps them working well for a long time. Regular upkeep can help avoid problems like breaking or rusting. If you skip maintenance, you might face issues like:

- Reduced performance

- Increased wear and tear

- Shorter tool lifespan

Remember, a little care goes a long way. Spending a few minutes on maintenance saves you money and time later. Think of it as a way to keep your DIY projects fun and easy!

Why is regular maintenance important?

Regular maintenance helps tools last longer and work better. A well-maintained tool can make tasks easier and safer. It also helps avoid costly repairs!

Essential Tools for Wood Lathe Maintenance

List of tools required for effective maintenance.. Tips on selecting the right quality tools for longevity..Keeping your wood lathe in top shape requires the right tools. Here’s a list of essential items:

- Wrenches for tightening bolts.

- Screwdrivers for adjusting parts.

- Wire brushes for cleaning debris.

- Lubricants to keep moving parts smooth.

- Measuring tools for accuracy.

When picking tools, focus on quality for durability. Look for trusted brands and check reviews. A well-made tool lasts longer and works better. Remember, good tools can make maintenance easier!

What tools do I need for wood lathe maintenance?

You need wrenches, screwdrivers, wire brushes, lubricants, and measuring tools.

Daily Maintenance Tasks

Quick checklist of daily maintenance actions.. How daily checks can prevent longterm problems..Daily checks help keep your wood lathe working well. With a simple checklist, you can spot problems early. This saves time and money later. Here are some quick tasks to do each day:

- Check the belt for wear and tear.

- Clean dust and debris from the machine.

- Inspect the tools for sharpness and damage.

- Lubricate moving parts to keep them running smoothly.

- Look for any loose screws or parts.

Doing these tasks helps you avoid bigger issues. Think of it like brushing your teeth. Daily care prevents cavities. Regular maintenance keeps your lathe safe and efficient.

Why is daily maintenance important?

Daily checks keep your wood lathe in great shape. They help prevent long-term problems and ensure safety while you work. Just a few minutes each day makes a big difference.

Monthly Maintenance Procedures

Detailed outline of monthly checks and tasks.. Focus on cleaning, inspecting, and common repairs..Every month, give your wood lathe a little TLC to keep it spinning smoothly! Start with a good clean to remove dust and shavings. Next, inspect the drive belt for wear—if it looks like a potato chip, it’s time for a change! Don’t forget about the chuck; check for tightness and cleanliness. Lastly, a little oil can go a long way for joints and bearings. Trust us, your lathe will thank you with smooth turns and no odd noises!

| Task | What to Look For | Action |

|---|---|---|

| Clean the Lathe | Dust and debris | Wipe with a cloth |

| Inspect Drive Belt | Signs of wear | Replace if damaged |

| Check Chuck | Tightness and cleanliness | Adjust and clean |

| Lubricate Joints | Dry or noisy parts | Apply oil |

Seasonal Maintenance Checklist

Description of seasonal tasks specific to temperature and humidity changes.. Tips on preparing the wood lathe for various environmental conditions..As the seasons change, your wood lathe needs some love too. In summer, keep it cool by checking for humidity. Too much moisture can ruin your wood. In winter, make sure to lubricate the moving parts to prevent rust. A little TLC goes a long way!

Here’s a fun checklist to help you remember:

| Season | Tasks |

|---|---|

| Spring | Clean off dust and check for wood chips. |

| Summer | Check humidity levels and oil moving parts. |

| Fall | Inspect for rust and clear any debris. |

| Winter | Lubricate components to prevent freezing. |

Prepare your lathe for changes with a quick review. A happy lathe makes happy woodworkers!

Signs Your Wood Lathe Needs Repair

Key indicators that suggest your lathe is in need of more than routine maintenance.. How to assess the need for professional repairs..Your woodworking machine might whisper when it needs attention. Here are some signs to look out for:

- Strange noises: If you hear grinding or squeaking, it may need repair.

- Vibration: Excessive shaking during use signals something isn’t right.

- Inconsistent speed: If the lathe’s speed varies, it might need a check.

- Burn marks: These can mean dull blades or poor alignment, requiring immediate help.

If you notice any of these issues, it’s time to think about professional repairs. Always trust your instincts when it comes to safety!

How do I know if my wood lathe needs professional repair?

Look for strong signs like strange noises or excessive vibration. If you see consistent problems, don’t hesitate to ask an expert!

Tips for DIY Maintenance vs. Professional Help

Guidance on what maintenance tasks are suitable for DIY.. Situations where professional maintenance is advisable..Some maintenance tasks are easy for you to handle yourself. You can clean, oil, and check your wood lathe’s parts. This keeps it running smoothly. However, some fixes are best left to the pros. For example, if the motor breaks, you should call an expert. They have the skills to fix it safely.

- DIY Tasks: Cleaning, lubricating, and minor adjustments.

- Professional Help: Motor repairs, electrical issues, and complex setups.

What Maintenance Tasks Can I Do Myself?

You can do many simple maintenance tasks yourself, like cleaning the lathe and checking for loose parts. Regular upkeep can extend your lathe’s life.

When Should I Call a Professional?

If the machine has major issues, like a broken motor, it’s best to get a professional’s help. They can ensure it’s fixed properly and safely.

Conclusion

In conclusion, a DIY wood lathe maintenance schedule helps keep your equipment in good shape. Clean your lathe regularly and check for wear and tear. Lubricate moving parts and keep the workspace tidy. By following these steps, you can extend your lathe’s life. For more tips on maintenance, check out our full guide or ask a friend who’s skilled at woodwork!FAQs

What Are The Essential Maintenance Tasks To Perform On A Diy Wood Lathe To Ensure Optimal Performance?To keep your DIY wood lathe working well, you should do a few simple tasks. First, clean it regularly to remove wood chips and dust. Next, check the belts and pulleys for wear; replace them if they look damaged. You should also oil the moving parts so they work smoothly. Finally, make sure the lathe is level and stable on its base.

How Often Should I Clean And Lubricate The Moving Parts Of My Wood Lathe?You should clean and lubricate your wood lathe every few months. If you use it a lot, do this more often. Dust and wood shavings can build up and slow it down. Keeping it clean helps it work better and last longer. Always check for dirt and add some oil to moving parts when needed.

What Components Of A Diy Wood Lathe Require Regular Inspection, And How Do I Check Their Condition?You should check the motor, belt, bearings, and tool rest on your wood lathe. Look for cracks or wear on the motor and belt. Spin the bearings slowly to see if they feel smooth and quiet. For the tool rest, make sure it is stable and not wobbly. Regular checks help keep your lathe working well!

Are There Any Specific Tools Or Products Recommended For Maintaining Wood Lathe Components?To keep your wood lathe in good shape, you can use a few simple tools. A soft cloth helps to wipe off dust and wood chips. Lubricating oil helps keep parts moving smoothly. You might also need a screwdriver for tightening screws. Remember to check everything regularly to make sure it works well!

What Signs Indicate That My Wood Lathe Needs Maintenance Or Repairs?You should check your wood lathe for strange noises when it runs. If it feels wobbly or shakes, that’s a sign, too. Also, look for rust or damage on the parts. If the motor doesn’t start or stops suddenly, it needs help. Regular checks can keep your lathe working well!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Maintenance Tasks To Perform On A Diy Wood Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your DIY wood lathe working well, you should do a few simple tasks. First, clean it regularly to remove wood chips and dust. Next, check the belts and pulleys for wear; replace them if they look damaged. You should also oil the moving parts so they work smoothly. Finally, make sure the lathe is level and stable on its base.”}},{“@type”: “Question”,”name”: “How Often Should I Clean And Lubricate The Moving Parts Of My Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should clean and lubricate your wood lathe every few months. If you use it a lot, do this more often. Dust and wood shavings can build up and slow it down. Keeping it clean helps it work better and last longer. Always check for dirt and add some oil to moving parts when needed.”}},{“@type”: “Question”,”name”: “What Components Of A Diy Wood Lathe Require Regular Inspection, And How Do I Check Their Condition? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the motor, belt, bearings, and tool rest on your wood lathe. Look for cracks or wear on the motor and belt. Spin the bearings slowly to see if they feel smooth and quiet. For the tool rest, make sure it is stable and not wobbly. Regular checks help keep your lathe working well!”}},{“@type”: “Question”,”name”: “Are There Any Specific Tools Or Products Recommended For Maintaining Wood Lathe Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your wood lathe in good shape, you can use a few simple tools. A soft cloth helps to wipe off dust and wood chips. Lubricating oil helps keep parts moving smoothly. You might also need a screwdriver for tightening screws. Remember to check everything regularly to make sure it works well!”}},{“@type”: “Question”,”name”: “What Signs Indicate That My Wood Lathe Needs Maintenance Or Repairs? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your wood lathe for strange noises when it runs. If it feels wobbly or shakes, that’s a sign, too. Also, look for rust or damage on the parts. If the motor doesn’t start or stops suddenly, it needs help. Regular checks can keep your lathe working well!”}}]}