Turn an old motor into a functional DIY wood lathe. This step-by-step guide shows beginners how to build an essential woodworking tool affordably, transforming junk into a valuable workshop asset with common materials and basic tools.

Ever look at an old appliance motor and think, “What can I do with this?” Many of us have a surplus of old motors gathering dust. The frustration of needing a wood lathe for your projects but finding them costly can be a real roadblock for budding woodworkers. But what if I told you that you could build your very own, perfectly functional wood lathe using one of those old motors? It’s not just possible; it’s a fantastic way to save money, learn about mechanics, and create a truly satisfying project. This guide will walk you through turning that old motor into an essential part of your workshop, step by simple step.

Why Build a DIY Wood Lathe From an Old Motor?

Building your own wood lathe from an old motor offers several compelling advantages, especially for beginners and hobbyists on a budget. It’s a project that combines resourcefulness with practical woodworking skills.

- Cost Savings: New wood lathes can be quite expensive, especially for beginners who are just starting their workshop journey. Repurposing an existing motor drastically cuts down on the main component cost.

- Skill Development: This project is an excellent learning opportunity. You’ll gain hands-on experience with basic electrical wiring, mechanical assembly, and understanding how machinery works.

- Customization: You can tailor the design to fit your specific needs and workshop space, something often not possible with off-the-shelf machines.

- Sustainability: Giving an old motor a new life is an eco-friendly approach, reducing waste and promoting a circular economy in your workshop.

- Satisfaction: There’s immense pride in using a tool you’ve built yourself. It adds a personal touch to every project you create with it.

Essential Components of Your DIY Wood Lathe

Before we dive into the building process, let’s get familiar with the core parts that make up a functional wood lathe. Understanding these components will make the assembly much clearer.

| Component | Description | DIY Considerations & Examples |

|---|---|---|

| Motor | Provides the rotational power for the spindle. | Old washing machine, treadmill, or fan motors (around 1/4 to 1/2 HP is often sufficient for light woodworking). Ensure it has enough torque. |

| Bed/Frame | The stable base that supports all other components and withstands vibrations. | Scrap lumber (e.g., 2x4s, plywood), metal angle iron, or even an old sawhorse. Needs to be rigid. |

| Headstock | Houses the spindle and bearings, holding the workpiece at one end. | Can be fabricated from wood, metal plates, or repurposed bearings from old machinery. Crucial for smooth rotation. |

| Tailstock | Supports the other end of the workpiece, especially for longer turning. Often adjustable. | Can be made from wood or metal, sliding along the bed. Needs to be sturdy and lockable. Has a screw mechanism for advancing a spur center. |

| Tool Rest | A bar that the turning tools rest on, allowing for controlled cutting of the wood. | Typically a metal rod or bar attached to an adjustable post that slides along the bed. |

| Spindle/Drive System | Connects the motor shaft to the workpiece, allowing the wood to spin. | Often involves a pulley system for speed reduction and a drive center (spur for the headstock) and a live center (in the tailstock). |

| Switch & Wiring | Safely controls the motor’s power. | A simple on/off toggle switch, power cord, and appropriate wire connectors. Safety is paramount here. |

Tools and Materials You’ll Likely Need

Gathering your tools and materials beforehand makes the building process much smoother. Here’s a list of common items you’ll require. Always prioritize safety gear!

Safety First!

Always wear safety glasses, and consider hearing protection and a dust mask when cutting or sanding. Ensure all electrical connections are secure and insulated.

Tools

- Drill and drill bits (various sizes)

- Screwdriver set

- Wrenches and sockets

- Saw (hand saw, jigsaw, or circular saw for wood)

- Measuring tape

- Clamps

- Sandpaper

- Wire strippers and crimpers

- Soldering iron (optional, for more robust electrical connections)

- Angle grinder (if working with metal components)

Materials (Examples, adapt to your design and found parts)

- Old Electric Motor: From appliances like washing machines, refrigerators, or old fans. A 1/4 HP to 1/2 HP motor is a good starting point.

- Stock for Bed: Sturdy lumber (e.g., 2x4s, 4x4s, a length of hardwood) or metal profiles.

- Headstock Components: Could involve bearings from old machinery, a large bolt for the spindle, or a repurposed pulley.

- Tailstock Components: More lumber, a threaded rod with a handle, and a way to secure it. A bearing or bushing for smooth sliding is helpful.

- Tool Rest Bar: A piece of solid metal rod (e.g., 1/2 inch steel rod) or a thick steel bar.

- Fasteners: Screws, bolts, nuts, washers.

- Pulley System: If your motor shaft isn’t directly usable. You might need a motor pulley and a headstock pulley.

- Drive Spur & Live Center: You can buy these relatively inexpensively, or for a more advanced DIY, fabricate them.

- On/Off Switch: A standard electrical switch rated for the motor’s amperage.

- Power Cord: A suitable grounded power cord.

- Wire Connectors: To securely join electrical wires.

- Paint/Finish: To protect your creation and make it look sharp.

Step-by-Step: Building Your DIY Wood Lathe

This guide provides a general framework. Your specific design will depend heavily on the materials you find. Be creative and adapt!

Step 1: Prepare the Motor

Image: An old motor cleaned and ready for integration.

First, safely extract your chosen motor from its original appliance. Clean it thoroughly. Identify the motor shaft and the electrical connection points. If it’s a shaded pole motor (common in fans), it might not have enough torque for woodworking. A capacitor-start or split-phase motor (often found in washing machines or larger appliances) is usually a better choice. You’ll need to understand its wiring diagram to connect it to a power cord and switch.

If you’re unsure about motor wiring, consult resources like Family Handyman’s guide to wiring a switch or seek help from someone experienced with electrical work. Safety is paramount when dealing with electricity.

Motor Types to Consider (and Why):

- Universal Motors (e.g., from drills, routers): High RPM, but can be noisy and have less consistent torque. Often require speed control.

- Induction Motors (e.g., from washing machines, fans): Generally more robust and reliable for continuous use. Speed is usually fixed unless you use a pulley system.

Step 2: Construct the Bed/Frame

The bed needs to be a strong, stable foundation. For a simple design, two long pieces of sturdy wood (like 2x4s or even 4x4s) spaced apart can form the main rails. You’ll then add cross-pieces for rigidity and to mount the headstock and tailstock.

- Cut your chosen lumber to the desired length for your lathe’s bed. Aim for at least 2-3 feet for basic turning.

- Add cross supports at intervals to keep the main rails parallel and provide mounting points. One near the headstock end, one near the tailstock end, and possibly one or two in the middle.

- Ensure the entire frame is squared up and incredibly rigid. You don’t want it vibrating excessively when the motor is running.

Step 3: Build the Headstock

The headstock is where the motor mounts and drives the workpiece. This is often the most complex part to get right.

- Mounting the Motor: You can bolt the motor directly to a sturdy block of wood or a metal plate that is then securely attached to the headstock end of your bed. Ensure the motor shaft overhangs enough to attach a pulley or drive spur.

- Spindle System:

- Direct Drive (Simple): If your motor has a suitable shaft, you might directly attach a drive spur to it. This means the workpiece spins at the motor’s RPM, which can be very fast.

- Pulley System (Recommended): A pulley system allows you to reduce the RPM and increase torque. You’ll need a pulley on the motor shaft and a larger pulley on the headstock spindle. The headstock spindle itself needs to be mounted in bearings to allow smooth rotation. You can salvage bearings from old machinery or purchase pillow block bearings. The spindle can be a sturdy bolt or threaded rod with a drive spur mounted on the end.

A well-functioning headstock is crucial for smooth, safe operation. For a more advanced build, consider looking at designs from reputable woodworking sites that detail bearing arrangements. For instance, Wood Magazine often features articles on shop-made tools and would have inspiration for robust headstock designs.

Step 4: Create the Tailstock

The tailstock provides support for longer workpieces and can accommodate drill bits for certain operations.

- Construct a base for the tailstock that can slide along the bed. This often involves a block of wood with a channel or rail that mates with your bed’s structure.

- Add a vertical upright to the sliding base.

- Mount a mechanism that allows you to hold a live center (or a drill bit) and advance it into the workpiece. A common method is to drill and tap a hole through the upright and use a threaded rod as a screw, with a handle on the end.

- Ensure the tailstock can be firmly locked in place on the bed, usually with a clamp or bolts.

Step 5: Fabricate the Tool Rest

The tool rest is where you’ll rest your chisels and gouges. It needs to be strong, smooth, and adjustable.

- A simple tool rest can be made from a sturdy metal rod (like a 1/2-inch steel rod) placed into a post.

- The post can be a piece of pipe or a threaded rod that slides into a bracket mounted to the bed. This bracket allows for easy positioning and locking of the tool rest up and down, and often forward and back.

- Ensure the top surface of the tool rest is smooth and at the correct height relative to the workpiece center.

The distance between the tool rest and the workpiece is a critical safety factor. Too close, and your tool can catch; too far, and you lose control.

Step 6: Wire the Motor and Switch

This is where electrical safety is non-negotiable.

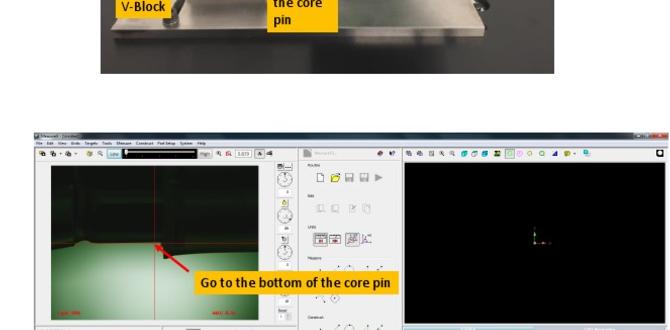

Image: A simplified wiring setup for a motor with an on/off switch.

If your motor has a simple two-wire connection (like some AC motors), it’s relatively straightforward: connect one wire from the power cord to one side of your switch, and the other wire from the switch to one motor terminal. Connect the remaining power cord wire directly to the other motor terminal.

For motors with more wires (like capacitor-start types), you’ll need to find a wiring diagram specific to your motor model. Look for labels on the motor or search online using the motor’s model number. Always use an insulated enclosure for your switch and ensure all connections are secure and insulated with wire nuts or heat shrink tubing.

Important Electrical Safety:

- Grounding: If your motor has a ground wire (usually green), connect it to the ground pin on your power cord and a metal part of your lathe’s frame (if applicable) for safety.

- Fuses/Breakers: Consider adding an in-line fuse holder between the power cord and the switch, rated appropriately for your motor’s amperage draw.

- Proper Insulation: Ensure no bare wires are exposed. Use appropriate wire connectors and electrical tape or conduit.

For detailed guidance on safe wiring practices, the Occupational Safety and Health Administration (OSHA) provides extensive resources on electrical safety in workplaces that can be adapted for home workshops.

Step 7: Assemble and Test

Now, put it all together!

- Mount the headstock assembly securely to the bed.

- Mount the tailstock assembly to the bed, ensuring it can slide and lock.

- Position the tool rest assembly, ensuring it’s adjustable.

- Connect the motor pulley to a corresponding pulley on the headstock spindle (if using a pulley system). Ensure belts are tensioned correctly.

- First Test (No Wood): Plug in the lathe and turn it on. Listen for any unusual noises or excessive vibrations. Check that the spindle spins smoothly. Turn it off and on a few times.

- Second Test (With Wood): Mount a small, scrap piece of wood between the drive spur and the live center. Start with a slow speed if possible. Turn on the lathe and let the wood spin. Check for stability.

- Gradually increase speed and test your tool rest position. Make any necessary adjustments.

Optional Enhancements for Your DIY Lathe

Once your basic lathe is functional, you might want to add some features to improve its performance and usability.

- Speed Controller: For AC induction motors, you can sometimes use a Variable Frequency Drive (VFD) if the motor is compatible. For simpler DC motors (like treadmill motors), a motor speed controller is often available. This offers much better control over turning speeds.

- Dust Collection Port: Integrate a port to connect a shop vacuum, helping to manage sawdust.

- Tool Storage: Add small shelves or hooks to keep your turning tools handy.

- Upgraded Bed: For more stability, consider using metal angle iron or a solid steel beam for the bed.

- Centers: Invest in higher-quality spur and live centers for better grip and smoother operation.

Troubleshooting Common Issues

Even the best DIY projects can hit a snag. Here are a few common problems and how to fix them:

| Problem | Possible Cause | Solution |

|---|---|---|

| Excessive Vibration | Unbalanced pulleys or workpiece, weak bed structure, loose components. | Ensure pulleys are balanced, workpiece is centered, bed is reinforced, and all bolts are tightened. Check motor mounting. |

| Motor Overheating | Motor is too small for the load, motor is overloaded, insufficient ventilation. | Reduce cut depth/speed, ensure cuts are light. Check for obstructions around the motor. Consider a larger motor or different pulley ratio. |

| Workpiece Slipping | Drive spur not biting into wood, tailstock pressure too low. | Ensure the drive spur is sharp and properly seated. Increase tailstock pressure using the screw mechanism. |

| Tool Catching / Chatter

|