An engine lathe, also known as a metal lathe, is a machine tool that has been around for centuries. It has played a crucial role in the industrial revolution and is an essential tool in metalworking today.

Engine lathes shape and turn metal parts, creating precision components for various applications. Engine lathes provide the precision and control required to produce high-quality workpieces from simple turning operations to more complex machining tasks.

We will explore the basic components of an engine lathe, different types of engine lathes, how they work, and their various applications. We will also discuss the setup, safety precautions, operating guidelines, tooling, common operations, troubleshooting, and maintenance of engine lathes. So, let’s dive into the world of engine lathes and uncover the secrets of this fundamental tool in metalworking.

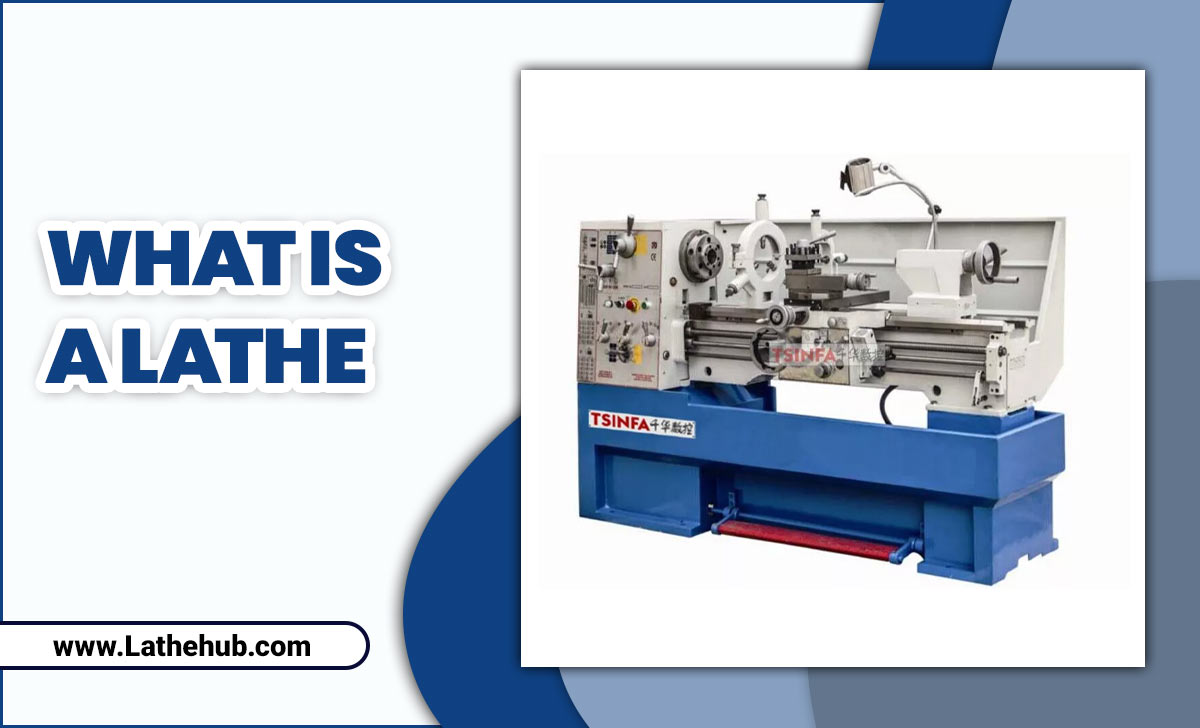

Basic Components Of An Engine Lathe

An engine lathe consists of several key components that perform machining operations. These components include the spindle, carriage, cross slide, tailstock, bed, and headstock. The spindle is the rotating shaft that holds and rotates the workpiece.

The carriage is the assembly that moves along the lathe’s bed, supporting the cutting tool and enabling longitudinal movement. The cross slide is mounted on the carriage and allows transverse movement, positioning the cutting tool relative to the workpiece. The tailstock serves as a support for the workpiece and can be adjusted for different lengths.

The bed is the horizontal base of the lathe, providing stability and supporting the other components. The headstock houses the spindle, gears, and other mechanisms that control the rotation of the workpiece. These components work harmoniously to ensure smooth and precise machining operations on the engine lathe.

Types Of Engine Lathes

Engine lathes come in various types, each designed to meet specific machining needs. Let’s explore some of the common types of engine lathes:

- Toolroom lathe: Toolroom lathes are precision lathes used for high-accuracy work, typically found in toolrooms of manufacturing facilities. They offer exceptional repeatability, precision, and control, making them ideal for producing complex parts with tight tolerances. Toolroom lathes often feature advanced features, such as digital readouts and automatic tool changers, to enhance productivity and machining accuracy.

- Turret lathe: Turret lathes, also known as capstan lathes, have specific designs to mass-produce small, intricate parts. They feature a turret tool post with multiple cutting tools, allowing quick and automatic tool changes. Turret lathes excel at repetitive operations, providing efficiency and reducing setup times.

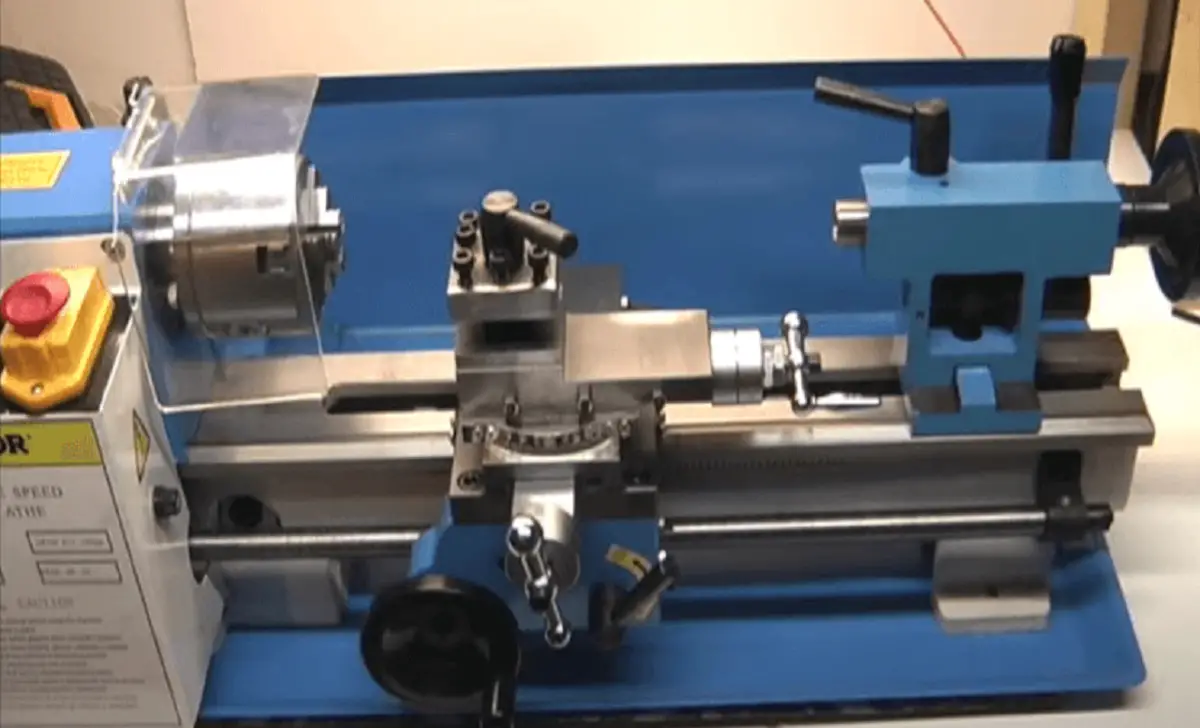

- Bench lathe: Bench lathes are small, portable lathes for light-duty applications, including hobbyist projects and small-scale production. They are compact, versatile, and easy to operate, making them popular among DIY enthusiasts and small workshops.

- CNC lathe: CNC (Computer Numerical Control) lathes are the modern iteration of engine lathes, revolutionizing the metalworking industry. These lathes are controlled by a computer, which drives the machining process with precision and automation. CNC lathes offer versatility, speed, and repeatability, making them indispensable in industrial manufacturing applications.

- Swiss lathe: Swiss lathes, also known as screw machines, are precision lathes used for producing small, intricate parts. They specialize in turning small bar stock, enabling high precision and control during machining. Swiss lathes are commonly handy in industries like medical, aerospace, and electronics, where extremely tight tolerances are required.

The wide range of engine lathes available today allows machinists to choose the most suitable machine for their specific machining needs, whether it’s precision work, high-volume production, or general metalworking applications.

What Is An Engine Lathe & How Does It Work

At its core, an engine lathe is a machine tool used to shape metal parts. It relies on the interaction between a rotating workpiece and a cutting tool to create flat surfaces, threads, and other machined features. The term “engine lathe” originated during the Industrial Revolution, when steam power was used to drive these machines.

Today, engine lathes can be powered by electric motors or other means, but the fundamental principles remain the same. By rotating the workpiece against a cutting tool, the engine lathe enables machinists to shape metal with precision and control, creating components for various industries.

Setup And Safety Precautions

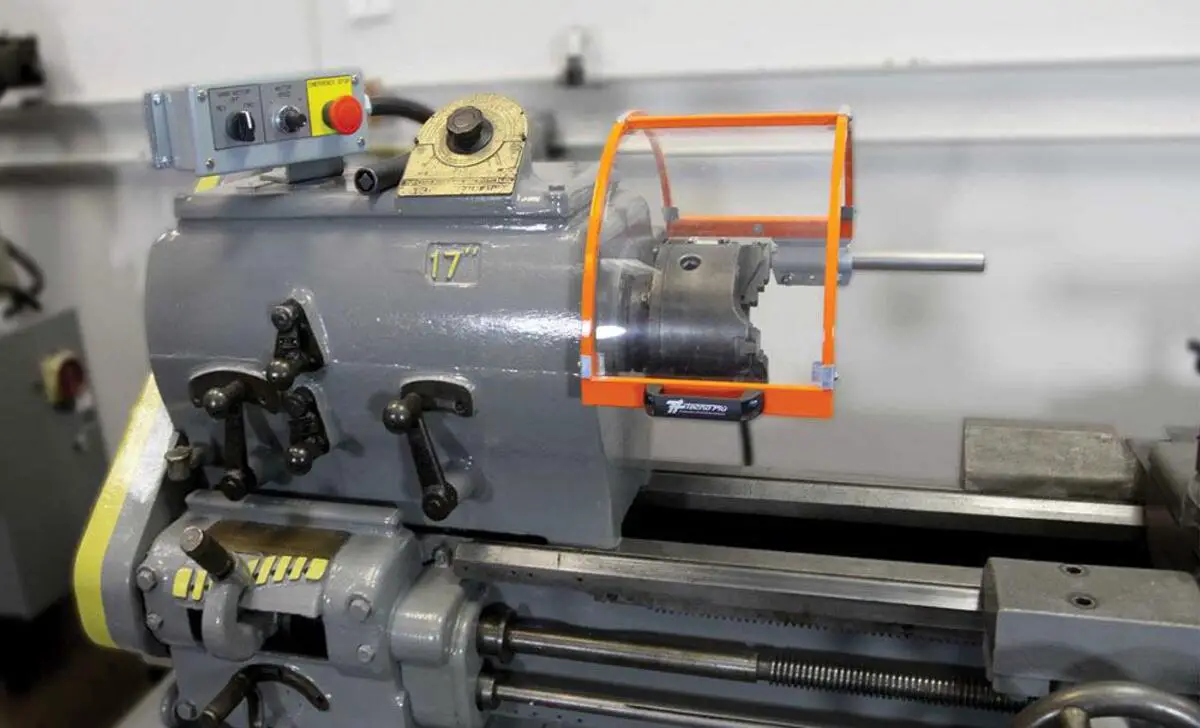

Setting up an engine lathe is critical to ensure safe and accurate machining operations. Before using the lathe, it should be properly leveled and securely bolted to the floor to prevent unwanted movement during operation. Personal protective equipment, such as safety glasses, ear protection, and appropriate clothing, should always be worn.

One of the essential safety precautions when operating an engine lathe is using chuck guards, which protect operators from rotating parts and flying debris. Emergency stop buttons should also be easily accessible, allowing operators to halt the machine quickly in case of an emergency.

Proper lubrication of moving parts, including the spindle, carriage, and tailstock, is crucial for smooth operation and to prevent premature wear. Following the lathe’s manual and adhering to all safety guidelines, including workpiece securing techniques, is essential to prevent accidents and ensure the safe operation of the machine.

Regular lathe inspection, including checking for any loose parts or damaged components, will help identify potential hazards and ensure that all safety features, such as chuck guards and emergency stops, are functional.

Operating An Engine Lathe: Step-By-Step Guide

Operating an engine lathe requires careful attention to detail and adherence to proper procedures. Here is a step-by-step guide to operating an engine lathe:

- Mount the workpiece: securely in the lathe chuck or between centers, ensuring you properly align and secure it.

- Select cutting tool: Choose the appropriate cutting tool for the desired machining operation, considering workpiece material, cutting speed, and feed rate.

- Set the cutting speed and feed rate: Adjust the lathe’s spindle speed and feed rate to achieve the desired cutting conditions. These settings depend on the workpiece material, tooling, and machining operation.

- Position the tool: Use the carriage and cross slide to position the cutting tool relative to the workpiece, ensuring proper tool height, angle, and clearance.

- Make initial cuts: Engage the power feed or manually feed the cutting tool into the workpiece, making the initial cuts. Monitor the cutting process and adjust the feed rate, depth of cut, and tool position as needed.

- Measure workpiece: Periodically measure the workpiece with precision instruments, such as calipers or micrometers, to ensure dimensional accuracy. Make any necessary adjustments to tool position or cutting conditions.

- Complete the operation: Continue machining the workpiece, taking multiple passes if needed, until the desired dimensions and surface finish are achieved. Perform any additional steps, such as taper turning or facing, as the machining operation requires.

By following these steps and exercising caution, machinists can achieve accurate, high-quality machining results on an engine lathe.

- Mount the workpiece securely in the lathe chuck or between centers.

- Select the appropriate cutting tool and adjust the cutting speed and feed rate.

- Use the carriage and cross slide to position the tool and make initial cuts.

- Regularly measure the workpiece with precision instruments to ensure accuracy.

- Complete the operation by finishing, taper turning, or performing other required machining steps.

Tooling And Tool Holders For Engine Lathes

Engine lathes rely on various tooling and tool holders to perform different machining operations effectively. Common tooling and tool holders include chucks, collets, faceplates, tool holders, boring bars, turning tools, and threading tools.

- Chucks, Collets, And Faceplates: are handy to hold workpieces securely. They come in different sizes and designs, allowing machinists to choose the right option for their applications.

- Tool Holders: play a vital role in holding and positioning cutting tools. Quick-change tool posts, an essential tool holder type, enable rapid tool changes, improving productivity and reducing setup times.

- Boring Bars: are handy for large-diameter machining, creating holes with precise dimensions and surface finishes.

- Turning Tools: are the primary tools for turning operations and shaping the workpiece into the desired shape or diameter.

- Threading Tools: create internal and external threads, enabling machinists to produce threaded components of various sizes.

When selecting tooling and tool holders for engine lathes, machinists consider the workpiece material, machining operation, cutting forces, and tool accessibility. The right tooling and tool holders and proper tool height, angle, and cutting conditions ensure efficient and accurate machining on engine lathes.

Common Operations Performed On An Engine Lathe

Engine lathes can perform a wide range of operations, allowing machinists to create complex parts precisely. Common operations on an engine lathe include turning, facing, threading, drilling, and knurling.

- Turning: Turning operations involve rotating the workpiece and using a cutting tool to remove material, creating cylindrical or conical shapes. You can perform this operation on external surfaces to create shafts, cylinders, or other circular features or on internal surfaces to create holes or bores.

- Facing: Facing operations aim to create flat surfaces perpendicular to the workpiece’s axis. During this operation, the cutting tool moves radially across the workpiece, removing material to achieve the desired face.

- Threading: Threading operations involve cutting threads on the workpiece, creating both internal and external threads. It enables the assembly of threaded parts, such as screws, bolts, and nuts, providing a secure and adjustable connection.

- Drilling: Engine lathes can be handy for drilling operations, utilizing the lathe’s spindle and tailstock to create holes in the workpiece. This operation commonly adds holes for fasteners, shafts, or other components.

- Knurling: Knurling creates a textured pattern on the workpiece’s surface, often used for better grip or aesthetics. It involves pressing a hardened tool onto the rotating workpiece and embossing the desired pattern.

Additionally, engine lathes can perform other operations, such as taper turning, drilling, reaming, parting-off, grooving, and chamfering, allowing for various machining possibilities. Machinists can combine these operations to create intricate parts, meeting the requirements of various industries, including aerospace, automotive, and general manufacturing.

Troubleshooting And Maintenance Of An Engine Lathe

Like any machine tool, engine lathes require regular maintenance and occasional troubleshooting to ensure optimal performance. By following proper maintenance procedures, machinists can prolong the machine’s lifespan, maximize accuracy, and minimize downtime. Here are some key aspects of troubleshooting and maintenance for engine lathes:

- Troubleshooting: When encountering issues with an engine lathe, machinists should follow a systematic approach to identify and resolve the problem. This may involve checking for tool wear, adjusting tool geometry, inspecting machine condition, verifying workpiece setup, or reviewing cutting conditions. You should maintain documentation of troubleshooting steps and the resolution for future reference.

- Maintenance: Engine lathes should undergo regular cleaning, lubrication, and inspection of parts. This includes checking for loose or damaged components, lubricating moving parts, tightening loose fasteners, and ensuring proper alignment of machine components.

- Lubrication: Proper lubrication of engine lathes helps reduce friction, heat, and wear, ensuring the machine’s longevity. Lubrication points, types of lubricants, and recommended intervals can vary depending on the machine’s design and manufacturer’s recommendations.

- Alignment: Proper alignment of engine lathes is essential for accurate machining. Regularly checking and adjusting the lathe’s alignment, including spindle, tool, and tailstock, helps prevent premature wear, improve cutting performance, and maintain precision during machining operations.

- Spare Parts: Keeping an inventory of spare parts, such as belts, gears, and bearings, can help minimize machine downtime in a failure. Machinists should work with lathe manufacturers or suppliers to identify critical spare parts and establish a spare parts management system.

By implementing regular troubleshooting and maintenance practices, machinists can ensure safe operation, prolong the life of the engine lathe, and maintain consistent machining results.

Advanced Techniques And Applications Of Engine Lathes

Engine lathes have evolved, incorporating advanced techniques and features that expand their capabilities and applications. Let’s explore some of the advanced techniques and applications of engine lathes:

- Taper Attachment: A taper attachment is an accessory that allows engine lathes to produce precise, tapered workpieces. It enables machinists to accurately taper angles without relying solely on manual techniques.

- Thread Chasing Dial: This attachment allows engine lathes to produce threads with different leads and pitches, providing versatility for machining different threads, including metric, standard, and special threads.

- Duplicating Attachments: Duplicating attachments enable engine lathes to replicate complex profiles, contours, or surfaces. This attachment is useful for creating multiple workpieces with identical shapes or reproducing intricate parts.

- Hydraulic Tracing: Hydraulic tracing, also known as hydraulic copying, is a technique where the movement of a stylus is handy to control the cutting tool’s motion, replicating the profile of a master workpiece. This technique allows for accurate reproduction of intricate shapes and surfaces.

These advanced techniques, combined with the versatility and precision of engine lathes, expand the range of machining possibilities. Engine lathes, whether manual or CNC, find applications in various industries, including automotive, aerospace, medical, and general manufacturing, where precision and control are paramount.

Conclusion

Various industries use an engine lathe, a versatile tool, for shaping and machining metal workpieces. It comprises several basic components, such as the bed, headstock, tailstock, and carriage. Different engine lathes are available, including bench lathes, tool room lathes, and CNC lathes, each with unique features and capabilities.

Following proper setup and safety precautions is essential to operate an engine lathe safely. Familiarize yourself with the step-by-step guide for operating the lathe and understand the tooling and tool holders used. Common operations on an engine lathe include turning, facing, threading, and drilling.

Regular troubleshooting and maintenance should be carried out to ensure an engine lathe’s optimal performance and longevity. Additionally, advanced techniques and applications can be explored to expand the lathe’s capabilities.

Frequently Asked Questions

1.What Is The Difference Between An Engine Lathe And A Regular Lathe?

Ans: An engine lathe is a lathe that specifically has specific designs for machining cylindrical parts. It is often handy in metalworking and can perform turning, facing, drilling, and threading operations. On the other hand, a regular lathe is a more general term that can refer to any lathe machine, including engine lathes.

2.What Does An Engine Lathe Do?

Ans: An engine lathe is a machine handy for shaping and machining cylindrical workpieces. It rotates the workpiece against a cutting tool, allowing for various operations such as turning, facing, drilling, and threading.

3.What Is The Difference Between A Bench Lathe And An Engine Lathe?

Ans: A bench lathe is a smaller, more compact lathe typically used for light-duty work and hobbyist projects. On the other hand, an engine lathe is larger and more robust, designed for heavy-duty machining and industrial applications.

4.What Is The Difference Between A Tool Room Lathe And An Engine Lathe?

Ans: Typically, people use a tool room lathe for smaller, precision machining tasks and find it in tool rooms or small manufacturing facilities. On the other hand, an engine lathe is larger and more powerful, designed for heavy-duty turning operations in industries such as automotive and aerospace.

5.What Is CNC Full Form?

Ans: CNC stands for Computer Numerical Control. It is a manufacturing process that uses computerized controls to operate and control machine tools. CNC machines can be programmed to perform precise and complex operations, such as cutting, drilling, and shaping materials, with high accuracy and efficiency.