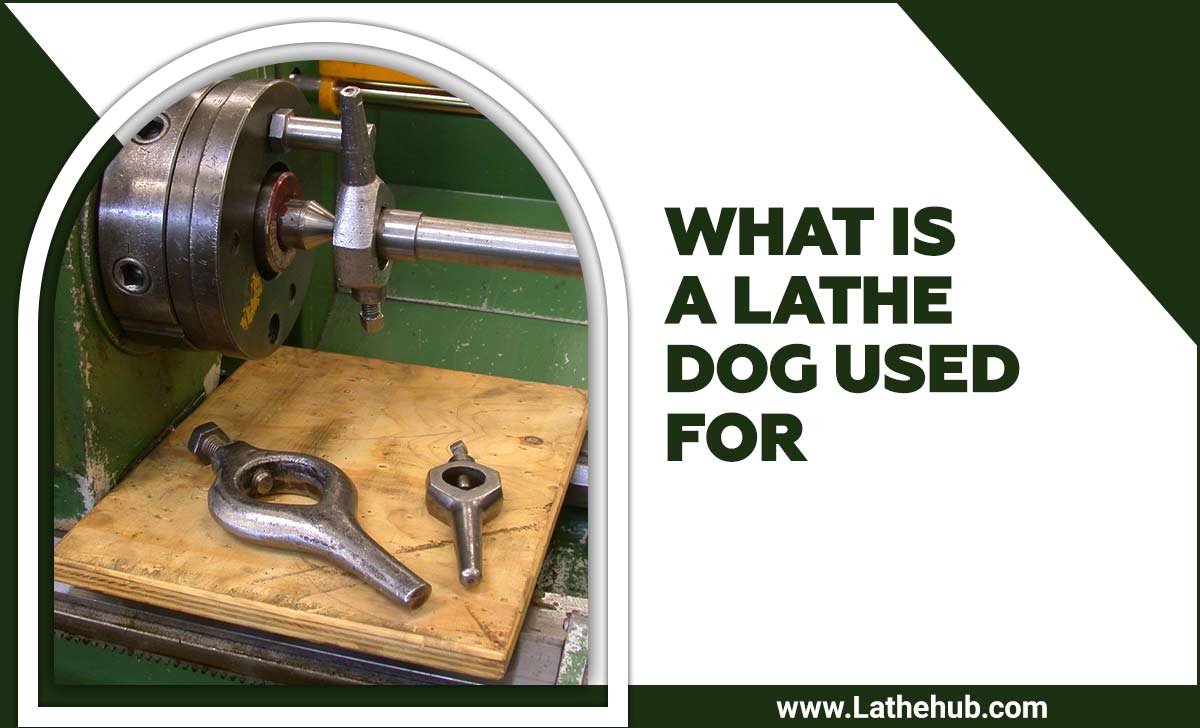

Are you curious about how things are made? Imagine a machine that can create parts with precision. That is where entry-level metal lathe automation comes in. These lathes are like magical tools that can shape metal into amazing forms.

When you hear “automation,” what pops into your mind? For many, it sounds like a future idea. However, entry-level metal lathe automation is already here, making life easier for hobbyists and beginners. Picture yourself stepping into a workshop where a metal lathe does the hard work. You can see your ideas come to life without hours of manual labor.

This technology not only saves time but also boosts creativity. Did you know that many small businesses start with basic lathes? They transform simple ideas into products we use every day. Learning about entry-level metal lathe automation can open doors to fun projects and endless possibilities.

So, what are you waiting for? Dive into the world of metal lathes and discover how they can change your creative journey. Your next project could be just a few turns away!

Entry-Level Metal Lathe Automation: A Comprehensive Guide

Entry-Level Metal Lathe Automation

Entry-level metal lathe automation makes machining easier for beginners. Imagine a machine that can cut metal shapes quickly, letting you focus on creativity. These tools use technology to increase speed and precision in tasks. Many people find it exciting to learn how these lathes work. Fun fact: automated lathes can complete jobs in just minutes that used to take hours! With proper guidance, anyone can master these machines and explore new projects.Benefits of Entry-Level Metal Lathe Automation

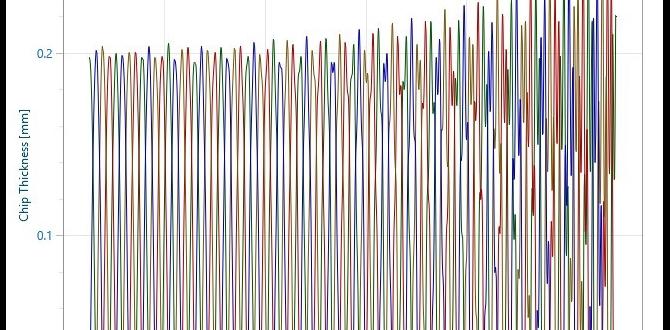

Cost efficiency for small businesses and hobbyists. Increased precision and repeatability in machining processes.Automating an entry-level metal lathe is like giving your shop a superhero upgrade. It helps small businesses and hobbyists save cash while slashing error rates. With automation, machines perform tasks with increased precision and repeatability, making every cut spot on. Think of it as having a trusty sidekick that’s always on point. Instead of the usual guesswork, you get reliable results, which means less time fixing mistakes and more time crafting cool stuff!

| Benefits | Description |

|---|---|

| Cost Efficiency | Saves money for small businesses and hobbyists |

| Precision | Delivers more accurate machining |

| Repeatability | Ensures consistent results every time |

Key Features to Look for in Entry-Level Automated Metal Lathes

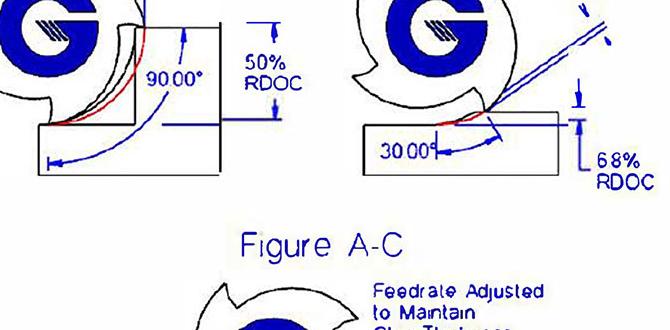

Types of automation systems (CNC, semiautomated). Essential specifications (spindle speed, tool capacity, etc.).When choosing an entry-level automated metal lathe, look for these key features. Two main types of automation systems are CNC and semi-automated. CNC allows full control through a computer, while semi-automated needs some manual input. Also, check important specs like:

- Spindle Speed: This affects how fast the machine works.

- Tool Capacity: This shows how many tools the lathe can hold.

- Accuracy: Higher accuracy means better finished products.

Choosing the right features can help you make quality parts.

What types of automation systems are there for entry-level metal lathes?

The two main types are CNC and semi-automated. CNC is more advanced, offering full control through software. Semi-automated systems need some manual help.

What essential specifications should I consider?

Consider spindle speed for efficiency and tool capacity for versatility. These specs make a big difference in performance and flexibility.

Popular Entry-Level Metal Lathe Automation Models

Review of leading models available in the market. Comparison of features, pricing, and user feedback.Many exciting entry-level metal lathe automation models are available today. These machines are great for beginners. They offer various features at different prices. Here are some popular models to consider:

- Model A: Affordable, easy to learn, and has great user reviews. It costs $1,200.

- Model B: Features advanced tools, priced at $1,800. Users love its speed and accuracy.

- Model C: Best for hobbyists, priced at $950. It has solid feedback for beginner projects.

Choosing the right model is important. Think about your budget and needs. Each model has something special to offer.

What models are best for beginners?

The best models for beginners include Model A, Model B, and Model C. They are easy to use and receive positive feedback from users.

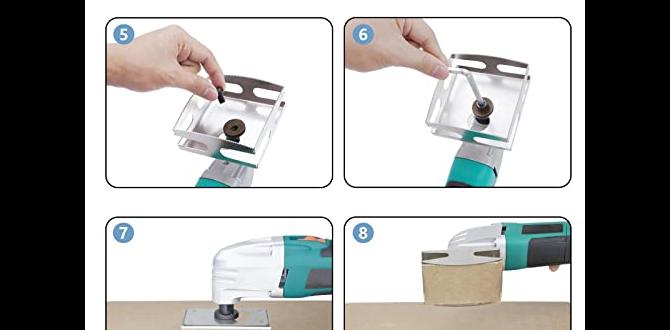

Setting Up Your Automated Metal Lathe

Stepbystep guide on installation and configuration. Best practices for initial setup and calibration.Getting your automated metal lathe ready is like prepping for a big school project. First, check that all parts are in the box. Make sure you have the manual, tools, and safety gear. Set it up on a flat surface to prevent any wobbling. Start by following the steps in the manual. You know, the one that looks like it’s written in a secret code?

Next, calibration is key. Think of it as tuning your favorite guitar; if it’s off, you’ll sound like a cat in a blender! Adjust the settings according to your project needs. Here are some best practices:

| Step | Description |

|---|---|

| Level the Lathe | Ensure it’s even to avoid mistakes |

| Check Tool Alignment | Make sure everything is lined up |

| Test Runs | Run a few tests before the real deal |

By following these steps, your metal lathe will work like a dream! Remember, practice makes perfect. Don’t be afraid to hit ‘start’ and enjoy the process!

Maintenance Tips for Automated Metal Lathes

Routine maintenance checks to ensure optimal performance. Common issues and troubleshooting techniques.Keeping an automated metal lathe in top shape is like taking care of a pet; it needs attention! Routine checks are key. Look for loose parts, clean the tools, and check the oil levels. Regular maintenance can prevent big headaches later. You wouldn’t ignore a funny noise from your car, right?

| Common Issues | Troubleshooting Tips |

|---|---|

| Strange vibrations | Check for loose screws and tighten them |

| Inconsistent cuts | Inspect your tool alignment and adjust as needed |

| Unexpected stops | Examine electrical connections and replace worn cables |

If your lathe acts up, it’s better to act fast! Even a small problem can lead to big repairs later. So, keep those wrenches handy, and your lathe will reward you with smooth performance!

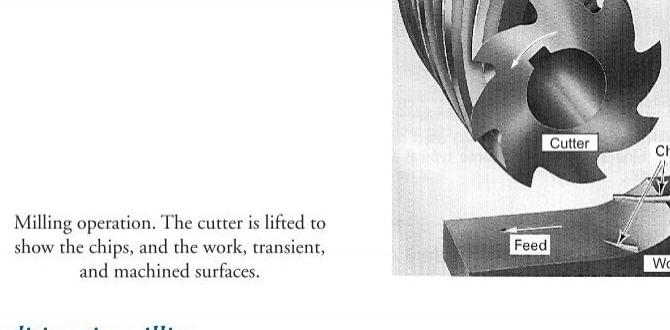

Real-World Applications of Entry-Level Metal Lathe Automation

Industries benefiting from automated lathes (aerospace, automotive, etc.). Examples of projects and outcomes achieved with automation.Many industries are hopping on the train of automated lathes. The aerospace and automotive sectors lead the charge. Think about it: precision parts for airplanes or cars don’t have room for mistakes. With automation, manufacturers can produce these parts faster and more accurately. Projects like making turbine blades for jets show how powerful these machines can be. In fact, companies report up to a 30% increase in efficiency with automation!

| Industry | Project Example | Outcome |

|---|---|---|

| Aerospace | Turbine Blade Manufacturing | Increased precision and speed |

| Automotive | Engine Component Production | 30% efficiency boost |

Future Trends in Metal Lathe Automation

Innovations in technology shaping the future of metalworking. Predictions for the growth of automated solutions in entrylevel markets.Technology is spinning at full speed! New gadgets and smart tools are changing how we work with metal. In the world of entry-level metal lathe automation, innovations are making machines easier to use and more efficient. For example, robots can do the boring tasks while humans take care of the fun stuff, like designing cool projects. Experts believe the demand for automated solutions will grow by over 20% each year. This makes working with metal not just easier, but way more exciting!

| Trend | Impact |

|---|---|

| Robotics Integration | Increases speed and accuracy |

| Smart Sensors | Improves safety and monitoring |

| User-Friendly Interfaces | Makes automation accessible to everyone |

Conclusion

In conclusion, entry-level metal lathe automation makes machining easier and faster. You can produce quality parts with less effort. Learning about automation tools will help you succeed. We encourage you to explore more resources or tutorials. This knowledge will boost your confidence and skills in metalworking. Get started today and see how automation can improve your projects!FAQs

What Are The Key Features To Look For In Entry-Level Metal Lathes That Support Automation?When looking for entry-level metal lathes that can work with automation, you want a few important features. First, check for easy programming. This helps you set up tasks quickly. Next, look for good safety features, like emergency stops. You also want a reliable power source, so the machine runs smoothly. Lastly, make sure it has user-friendly controls, so you can understand how to use it.

How Can Beginner Machinists Effectively Integrate Automation Into Their Metal Lathe Operations?Beginner machinists can use simple tools to make their metal lathe operations easier. Start with a basic program that helps control the lathe. You can also use sensors to check if the pieces are right. As you get more comfortable, you can explore more advanced tools. This helps you create parts more quickly and accurately!

What Are The Benefits And Limitations Of Using Entry-Level Automated Metal Lathes For Small-Scale Production?Using entry-level automated metal lathes for small-scale production has some good points and some not-so-good points. They help you make pieces quickly and easily, saving time. They are also cheaper than bigger machines, making them perfect for small projects. However, they might not be as strong or precise for tough jobs. Sometimes, they can’t handle very big or complex parts, too.

What Types Of Automation Technologies, Such As Cnc Controls Or Robotic Arms, Are Compatible With Entry-Level Metal Lathes?Entry-level metal lathes can work with a few types of automation technologies. One common type is CNC controls, which helps you make precise cuts automatically. You can also use simple robotic arms to help move pieces around. These tools make it easier and faster to create metal parts. They can help you do more work with less effort!

How Can Software Tools Improve The Efficiency And Accuracy Of Automated Processes In Entry-Level Metal Lathe Setups?Software tools can help us set up metal lathes faster and more accurately. They show us how to adjust the machine, so we make fewer mistakes. With the right steps on the screen, we can follow them easily. This saves us time and makes our work better. Using these tools means we can create high-quality parts every time!