Have you ever wondered how those amazing metal creations are made? An entry-level metal lathe drive system is one of the first tools that can help you start your journey into metalworking. It’s like a magic wand for shaping metal!

You might ask, what exactly is a metal lathe? Picture a spinning piece of metal. The lathe carves it into beautiful shapes. With a simple drive system, even beginners can learn to use it.

Imagine making your very own metal parts or tools. It sounds cool, right? Many people start their workshop adventures with an entry-level lathe. These systems are user-friendly and offer great value for the money.

Did you know that lathes have been used for thousands of years? Ancient craftsmen used them to create everything from furniture legs to intricate designs. Today, modern technology makes it easier than ever to get started!

Understanding The Entry-Level Metal Lathe Drive System: An Overview

Summary of Entry-Level Metal Lathe Drive System

An entry-level metal lathe drive system is perfect for beginners. It helps budding machinists learn valuable skills. This system uses motors to spin metal, allowing users to cut, shape, and polish materials. Did you know that lathes are often called the “mother of machines”? They play a crucial role in manufacturing. Understanding this drive system makes it easier to create precise parts. With practice, anyone can master this useful tool!What is an Entry-Level Metal Lathe Drive System?

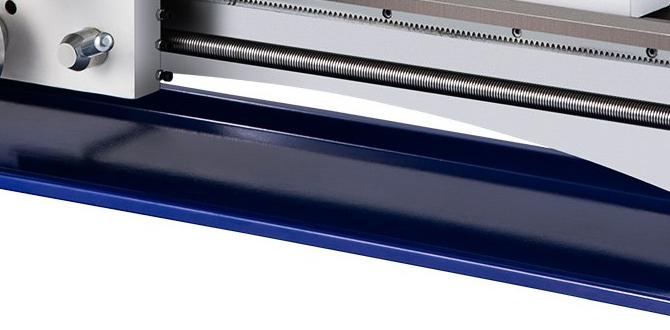

Definition and purpose of drive systems in metal lathes. Types of entrylevel metal lathes available in the market.An entry-level metal lathe drive system is like the heart of a lathe machine. It powers the tool, helping it spin and shape metal. Think of it as a magician’s wand that turns raw material into something useful! There are several types of these systems on the market, each with its own special tricks.

| Type | Features |

|---|---|

| Belt Drive | Simple and easy to use; great for beginners! |

| Direct Drive | More power, fewer parts—less chance of getting lost in the magic! |

| Variable Speed Drive | Gives you control; speed up or slow down like a pro! |

In short, these drive systems are essential for helping you create cool metal projects. Plus, each type offers unique benefits, making them as exciting as a roller-coaster ride for metalworking newbies!

Types of Drive Systems in Metal Lathes

Comparison of belt drive vs. direct drive systems. Advantages and disadvantages of each type.When choosing a drive system for an entry-level metal lathe, you have two main types: belt drive and direct drive. Each has its own perks and downsides.

- Belt Drive: This system uses belts to connect the motor to the lathe. It is quieter and absorbs shocks well. However, it can wear out over time and might require maintenance.

- Direct Drive: This system connects the motor directly to the lathe. It has fewer parts, which makes it simpler and more efficient. Yet, it can be noisier and may not handle heavy loads as well as belt drives.

Selecting the right drive system depends on your needs. Do you value quiet operation or efficiency? Each choice offers different benefits that fit various projects.

What is a belt drive system?

A belt drive system uses belts to transfer power from the motor to the lathe, making it quieter and more flexible.

What is a direct drive system?

A direct drive system connects the motor right to the lathe, providing fast and efficient operation.

Understanding these systems helps you make a better choice for your metal lathe projects.

Choosing the Right Entry-Level Metal Lathe Drive System

Factors to consider (workload, material types, budget). Recommendations for specific applications and projects.Picking the right drive system for your lathe can feel like searching for a needle in a haystack. Start by thinking about your workload. Will you be spinning lightweight plastic or heavy metal? Next, consider the material types. Different materials need different approaches! Lastly, don’t forget your wallet—your budget matters. The good news? There are many options out there for all kinds of projects. Below is a quick guide:

| Application | Recommended Drive System |

|---|---|

| Hobby Projects | Entry-Level DC Drive |

| Metalworking | Variable Speed Belt Drive |

| Wood Turning | Direct Drive System |

Maintaining Your Metal Lathe Drive System

Essential maintenance tips for optimal performance. Common issues and troubleshooting techniques.Taking care of your metal lathe drive system helps it work better and last longer. Regularly check for dirt and oil on the moving parts. Here are some maintenance tips:

- Keep everything clean.

- Check for loose bolts or parts.

- Lubricate moving parts regularly.

If something goes wrong, here’s how to troubleshoot:

- Listen for unusual noises.

- Look for vibrations or shaking.

- Stop immediately if it overheats.

These simple steps can keep your drive system running smoothly.

What common issues arise with a metal lathe drive system?

Common problems include overheating and misalignment. Regular checks help catch these before they become big issues.

Upgrading Your Drive System: When and Why?

Signs that indicate a need for an upgrade. Benefits of upgrading to a more advanced drive system.Sometimes, your metal lathe might start acting like a grumpy cat. If it stalls or makes weird noises, it might be time for an upgrade! An upgraded drive system can smooth out those bumps in your work. Imagine spinning metal like a pro.

Upgrading can lead to better precision and less wear and tear. Plus, no one wants to work harder than necessary. A new drive means you can get the job done faster and easier. Remember, a happy lathe creates happy projects!

| Signs You Need an Upgrade | Benefits of Upgrading |

|---|---|

| Frequent stalling | Improved speed |

| Unusual noises | Higher precision |

| Poor performance | Less maintenance |

Real-Life Applications of Entry-Level Metal Lathes

Industries and projects that utilize these drive systems. Case studies highlighting successful implementations.Entry-level metal lathes are like the cool kids at a school fair—they attract attention! Businesses like automotive repair shops and small manufacturers use these machines for various projects. They help create parts for cars, toys, and even furniture! For instance, a local shop used an entry-level lathe to craft custom knobs, making their products unique. This saved money and brought in happy customers. Talk about a win-win!

| Industry | Application |

|---|---|

| Automotive | Engine components |

| Manufacturing | Custom parts production |

| Arts and Crafts | Unique designs |

Resources for Further Learning

Recommended books, websites, and forums for metal lathe enthusiasts. Online courses and tutorials for handson learning.Picking up a metal lathe can be a fun adventure! For beginner enthusiasts, there are great resources out there. Check out books like “The Metal Lathe” by Tom K. McCauley for easy tips and tricks. Websites like the Machinist’s Workshop forum have friendly folks ready to share advice. Online courses on platforms like YouTube or Udemy make learning hands-on and enjoyable. Remember, practice makes perfect, and a little humor goes a long way—just don’t let the whiskers of your pet cat get caught in the lathe!

| Resource Type | Recommendations |

|---|---|

| Books | The Metal Lathe by Tom K. McCauley |

| Websites | Machinist’s Workshop Forum |

| Online Courses | YouTube & Udemy |

Conclusion

In summary, an entry-level metal lathe drive system is essential for beginners in metalworking. It helps you shape and cut materials easily. You can learn and practice basic skills with it. If you want to improve your projects, consider reading more about different lathe types and their features. Try experimenting with your own tasks to build confidence and creativity!FAQs

What Are The Key Components Of An Entry-Level Metal Lathe Drive System And How Do They Function Together?An entry-level metal lathe drive system has a few key parts. First, there’s the motor, which gives power to the lathe. The motor connects to belts that help spin the lathe’s main part called the spindle. The spindle holds the metal and rotates it while you work. Together, these parts help shape metal into different forms.

How Does The Power Output Of A Metal Lathe Drive System Affect Machining Capabilities And Material Compatibility?The power output of a metal lathe affects how well it can cut different materials. If a lathe has high power, it can easily work with hard metals. But if it has low power, it might struggle with tougher materials. This means that choosing the right lathe helps us get the job done better!

What Types Of Drive Systems Are Commonly Used In Entry-Level Metal Lathes, And What Are The Advantages And Disadvantages Of Each?Entry-level metal lathes usually have two types of drive systems: belt drives and direct drives. Belt drives use a belt to connect the motor to the lathe. They are quiet and can change speeds easily. However, they need more maintenance because belts can wear out. Direct drives connect the motor directly to the lathe. They are usually more powerful and need less maintenance. But, they can be loud and might be harder to change speeds.

How Can Users Maintain And Troubleshoot Their Entry-Level Metal Lathe Drive Systems To Ensure Optimal Performance?To keep your metal lathe running well, start by cleaning it regularly. Dust and dirt can cause problems. Check the drive belt for any signs of wear, like cracks. If it looks damaged, replace it to avoid issues. Lastly, listen for unusual sounds, like grinding. If you hear something strange, check the parts for anything loose or broken.

What Safety Considerations Should Be Taken Into Account When Operating An Entry-Level Metal Lathe With A Drive System?When using a metal lathe, wear safety goggles to protect your eyes from flying bits of metal. Keep your hands away from moving parts. Always tie back long hair and avoid loose clothing. Make sure to use the right tools and follow the machine’s instructions. Lastly, never operate the lathe when you are tired or distracted.