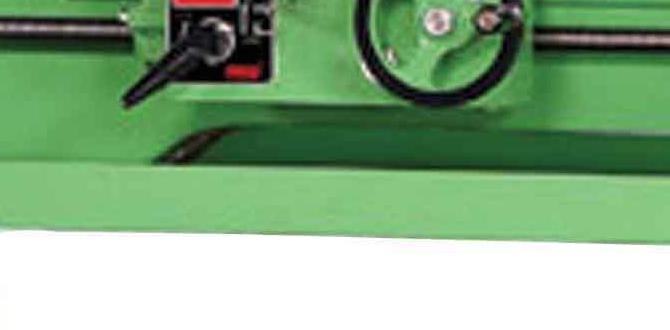

Imagine walking into a workshop filled with cool machines. One particular machine catches your eye: a metal lathe. It spins metal at high speeds to create parts and tools. Ever wondered how this amazing machine works? One key component is the entry-level metal lathe pulley.

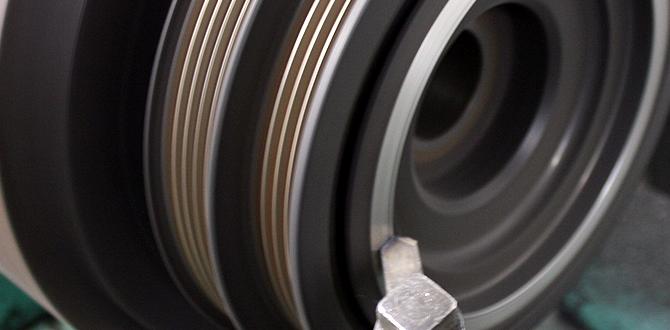

Entry-level metal lathe pulleys may seem simple, but they play a big role. They help transfer power from the motor to the lathe. Without them, the lathe wouldn’t move or function correctly. Have you ever tried to pedal a bike with a loose chain? It’s frustrating! That’s what happens when pulleys aren’t working right.

These pulleys come in different sizes and materials. It’s important to choose the right one for your lathe. Just like picking the right shoe for running, the right pulley makes all the difference. Interested in knowing more about how these parts work together? Let’s dive deeper into the world of metal lathes and discover more!

Entry-Level Metal Lathe Pulley: A Comprehensive Guide

Entry-Level Metal Lathe Pulley

Are you eager to dive into metalworking? An entry-level metal lathe pulley is a great start! It helps control the speed of your lathe, making your projects smoother. Imagine crafting beautiful designs with precision. You can easily adjust the settings, which lets you practice and improve your skills. Did you know that a sturdy pulley can last many years? This simple tool can unlock new projects and adventures in metalworking. Why wait? Start creating your masterpieces today!Understanding Metal Lathes

Definition and function of metal lathes. Importance of pulleys in the operation of metal lathes.Metal lathes are machines that shape metal into various forms. They spin the metal while cutting tools carve it into desired shapes, like creating a beautiful cup or a shiny spoon. Now, pulleys play a key role here. They transfer power from the motor to the lathe, helping it spin smoothly. Without pulleys, your lathe may just be a fancy paperweight! Think of pulleys as the muscles of the machine, making everything work in perfect harmony.

| Function | Importance of Pulleys |

|---|---|

| Shapes metal | Transfers power efficiently |

| Cuts with precision | Ensures smooth operation |

| Creates various designs | Reduces wear on the motor |

Key Features to Consider When Choosing a Pulley

Material and durability considerations. Dimensions and compatibility with different lathe models.Choosing the right pulley for your lathe can make all the difference. First, think about material and durability. Will it last? Look for strong materials like steel or aluminum. Next up, dimensions! Make sure the pulley fits your lathe model like a glove. Pulley size matters—a too-big pulley may cause trouble, while a too-small one just won’t fit. Remember, a good pulley should balance performance and compatibility!

| Feature | Consideration |

|---|---|

| Material | Steel or Aluminum for durability |

| Dimensions | Must fit your lathe model |

Installation Guide for Entry-Level Metal Lathe Pulleys

Stepbystep instructions for installation. Common issues and troubleshooting tips during installation.Installing an entry-level metal lathe pulley can be easy if you follow these steps:

- First, gather all tools like wrenches and screwdrivers.

- Next, turn off power to the lathe before starting.

- Remove the old pulley carefully.

- Align the new pulley with the spindle.

- Tighten bolts evenly to secure it.

- Finally, restore power and test the lathe.

Sometimes, you may face issues. Here are common problems and solutions:

- Pulley wobbles: Check if bolts are tight.

- Noise during operation: Lubricate the pulley.

Follow these steps, and you should have a smooth installation!

What is the best way to troubleshoot during installation?

If you encounter problems, always double-check your work. Make sure parts are aligned and secure. This can save time and avoid future issues!

Maintenance Tips for Longevity of Lathes and Pulleys

Routine checks and maintenance practices. Recommended cleaning and lubrication techniques.Keeping your lathe in great shape is easy with some simple steps. Regular checks help catch problems early. Make sure to look for wear and tear on your entry-level metal lathe pulley. Clean it often to remove dust and debris. Lubricate moving parts to keep everything running smoothly. A well-maintained lathe can last for years.

- Check for loose screws and tighten them.

- Remove dust with a soft cloth.

- Apply oil to gears and pulleys regularly.

How can I maintain my lathe and pulleys?

To ensure your lathe runs well, stick to regular cleaning and lubrication. Dust and grime can cause issues, so clean it regularly! This simple habit will help you work safely and efficiently. Remember, a little care goes a long way!

Popular Brands and Models of Entry-Level Metal Lathes and Pulleys

Review of top brands in the market. Features and pricing comparison of popular models.In the world of entry-level metal lathes, several brands stand out. Typically, you will find names like Grizzly, Jet, and Bolton at the top of the list. These brands offer reliable machines that help hobbyists and beginners create impressive projects. Let’s peek at some features and prices:

| Brand | Model | Features | Price |

|---|---|---|---|

| Grizzly | G8688 | High precision, 8-inch swing | $835 |

| Jet | JML-1014 | Integrated variable speed, easy controls | $1,200 |

| Bolton | BL-DC2540 | Two-axis digital readout, detachable tailstock | $999 |

These machines make turning metal a breeze! Prices vary widely, so choose wisely—your wallet will thank you. With features that save time, you’ll have more moments to celebrate your shiny new creations. Just imagine, you can be the proud owner of a metal masterpiece in no time!

Safety Precautions While Using Metal Lathes

Essential safety gear and practices. Guidelines for safe operation to prevent accidents.Using a metal lathe can be fun, but safety comes first! Always wear eye protection to shield your eyes from flying bits. Hearing protection is crucial if the machine is loud. Gloves can protect your hands, but make sure they aren’t too loose. Keep hair tied back and avoid loose clothes.

Follow these essential practices to stay safe:

- Check the machine for any parts that may be damaged.

- Know the emergency shut-off procedures.

- Focus on your work; distractions can lead to accidents.

- Never leave the machine running unattended.

What should I wear when using a metal lathe?

Always wear eye protection and ear protection. It’s also good to use gloves that fit snugly. Tie back long hair to keep it away from moving parts.

Real-World Applications of Metal Lathes with Pulleys

Examples of projects suitable for entrylevel users. Insights on how pulleys enhance project outcomes.Metal lathes with pulleys are great for beginners. They can create fun and useful projects. Here are some examples:

- Making small toys

- Crafting simple tools like handles

- Creating decorative items

Pulleys make these projects easier. They help control the speed and power of the machine. This means smoother cuts and better results. You get to enhance your skills while creating awesome things!

What can beginners make with a metal lathe and pulleys?

Beginners can make toys, tools, and decorative items.

Community Resources and Support for Metal Lathe Users

Online forums and groups for troubleshooting and tips. Recommended tutorials and workshops for skill enhancement.Finding help for using a metal lathe is easy! Online forums and groups give tips and troubleshoot problems. These spaces let users share ideas, ask questions, and learn together. You can also find great tutorials and workshops. They teach everything from the basics to special tricks.

- Join forums like Reddit and Facebook groups for instant advice.

- Look for YouTube channels dedicated to metal lathe skills.

- Attend local workshops to get hands-on experience.

What are some online resources for metal lathe users?

Forums, tutorials, and workshops are great resources for metal lathe users.Conclusion

In summary, an entry-level metal lathe pulley is essential for smooth machine operation. It connects the motor to the lathe, helping you shape metal with precision. If you’re starting a project, consider testing different pulleys for best results. We encourage you to read more about lathe setups and explore your options for a successful metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Entry-Level Metal Lathe Pulleys:Sure! Here are five questions about entry-level metal lathe pulleys. First, what are metal lathe pulleys? They help the lathe spin and move the tool. Second, why do we need them? They make the machine work better and more smoothly. Third, how do we choose the right one? You look at the size and how much weight it can hold. Fourth, can you replace them easily? Yes, it’s usually simple to change them if they break. Finally, where do we buy them? You can find them at hardware stores or online.

Sure! Please share the question you’d like me to answer, and I’ll be happy to help.

What Are The Key Features To Look For In An Entry-Level Metal Lathe Pulley?When looking for an entry-level metal lathe pulley, you should check a few important features. First, make sure it is the right size for your lathe machine. Look for a strong material that won’t break easily. Also, find one that is easy to change speeds. Lastly, check if it fits well with other parts of your lathe. These features will help you work better and safer!

How Do Different Pulley Sizes Affect The Performance And Functionality Of A Metal Lathe?Different pulley sizes change how fast the metal lathe works. A bigger pulley makes the lathe go faster, while a smaller pulley makes it slower. This lets you choose the right speed for the job. If you need to cut metal quickly, you pick a bigger pulley. If you want to work slowly and carefully, you choose a smaller one.

What Materials Are Commonly Used To Manufacture Pulleys For Entry-Level Metal Lathes, And What Are Their Advantages?Pulleys for entry-level metal lathes are usually made from plastic or aluminum. Plastic is light and does not rust, making it easy to use. Aluminum is strong and can handle heavy work without breaking. Both materials help make the lathe work smoothly and quietly.

How Can Improper Pulley Alignment Impact The Operation Of An Entry-Level Metal Lathe?Improper pulley alignment can cause problems for a metal lathe. When the pulleys are not lined up, the machine can shake. This makes it harder to cut metal evenly. You might end up with rough edges on your work. It can also wear out the parts of the lathe faster.

What Maintenance Practices Can Ensure The Longevity And Efficiency Of Pulleys On Metal Lathes?To keep pulleys on metal lathes working well for a long time, we should do regular checks. Make sure to clean them often to remove dust and dirt. You should also check for any loose parts and tighten them if needed. Adding a bit of oil can help them run smoothly. Finally, look for signs of wear and replace parts if they are damaged.