Have you ever wondered how machines like lathes work? Imagine a powerful tool that helps shape metal into amazing designs. An entry-level metal lathe is one of these tools. It’s great for beginners who want to learn. But how do you make it work? A clear and helpful wiring diagram can show you just that.

Think of it like a treasure map. Each wire leads you to the treasure of functionality. Understanding the entry-level metal lathe wiring diagram can seem tricky. Yet, with a little patience and guidance, you can unlock its secrets.

Did you know that many people start their engineering journey with a simple metal lathe? This tool teaches essential skills. Knowing how to wire it properly is the first big step toward building awesome projects. Ready to dive in and explore this exciting world?

Entry-Level Metal Lathe Wiring Diagram: A Comprehensive Guide

Understanding Entry-Level Metal Lathe Wiring Diagrams

Entry-level metal lathe wiring diagrams help beginners set up their machines safely. These diagrams show how to connect wires clearly. Knowing where each wire goes can prevent accidents. Have you ever wondered why a metal lathe is important? It’s a crucial tool in machining that allows precise shaping of metal. Understanding the wiring helps users maintain and troubleshoot their machines effectively. With the right wiring, you can start crafting metal parts with ease and confidence!Components Needed for Wiring an Entry-Level Metal Lathe

List of essential electrical components (motors, switches, etc.). Recommended tools and materials for wiring.Wiring an entry-level metal lathe requires important parts. Here is a list of key components:

- Electric Motor: Powers the lathe.

- Switch: Controls the electric flow.

- Connectors: Join wires together.

- Fuses: Protect the circuit from overloads.

- Wires: Carry electricity throughout.

You’ll also need tools like wire strippers, screwdrivers, and a multimeter. Materials should include electrical tape and wire connectors. Having the right items makes wiring safer and easier!

What tools do I need for wiring?

For wiring an entry-level metal lathe, you need essential tools. These tools include:

- Wire Strippers: To remove insulation from wires.

- Multimeter: To measure voltage and current.

- Screwdrivers: For tightening connections.

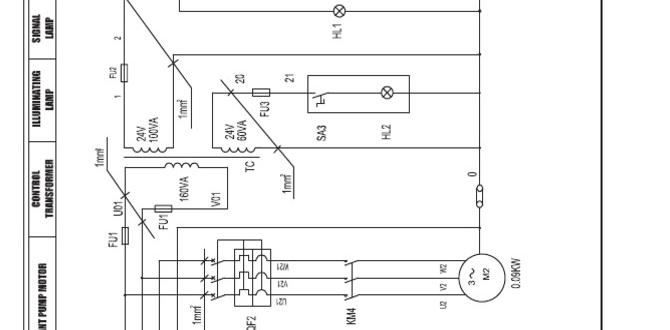

Step-by-Step Wiring Diagram Explanation

Detailed visual representation of the wiring process. Explanation of each connection and its function.A wiring diagram helps you understand how to connect parts. It shows where each wire goes. Connections have different jobs. Here’s a simple breakdown:

- Power Supply: Provides the energy to run the lathe.

- Motor Connection: Makes the lathe spin and work.

- Control Switch: Turns the machine on and off.

- Ground Wire: Keeps everything safe by preventing shocks.

Following this diagram carefully will help you wire your metal lathe correctly!

What should I know about the wiring process?

The wiring process is all about making the correct connections. It keeps your machine safe and working. Understanding the purpose of each connection is key!

Troubleshooting Common Wiring Issues

Identifying potential wiring problems. Solutions for common electrical issues in metal lathes.Wiring issues can confuse anyone. It’s good to know the signs. Common problems include:

- Loose connections causing errors

- Frayed wires leading to shorts

- Burnt fuses stopping operation

Fixing these problems can be easy:

- Check connections often

- Replace damaged wires right away

- Use the right fuse size

Always refer to your entry-level metal lathe wiring diagram for details.

What should I do if my metal lathe won’t turn on?

First, check for power. Make sure it is plugged in and the outlet works. Next, inspect wiring for any damage.

Safety Precautions for Metal Lathe Wiring

Essential safety gear and precautions to take. Recommended practices to follow during the wiring process.Using an entry-level metal lathe can be exciting, but safety comes first! Always wear protective goggles and gloves. These will keep your eyes and hands safe from flying debris. Make sure to turn off all power sources before you start wiring. It’s like taking off your shoes before entering a clean house—good manners! Don’t forget to double-check connections and use tools that are dry and insulated.

| Safety Gear | Precautions |

|---|---|

| Goggles | Always wear protective eyewear. |

| Gloves | Use gloves to prevent cuts. |

| Insulated Tools | Keep tools dry and safe. |

Following these tips can be the difference between a fun project and a trip to the emergency room, so wire wisely!

Upgrading Your Entry-Level Metal Lathe Wiring

Benefits of upgrading wiring for performance and safety. Recommended upgrades for enhanced functionality.Upgrading the wiring on your metal lathe can make your machine run better and safer. It’s like giving it a new pair of shoes—suddenly, it moves faster! Better wiring improves performance, reduces electrical issues, and even protects you from shocking surprises. Plus, you might find your projects finishing up faster, which means more time for snacks. Consider these upgrades for smoother function:

| Upgrade | Benefit |

|---|---|

| Heavy-duty wire | Improves current flow |

| Surge protector | Protects against voltage spikes |

| Quality connectors | Enhances durability |

These upgrades help avoid potential disasters. Remember, better wiring keeps your lathe—and you—working safely and efficiently!

FAQs About Entry-Level Metal Lathe Wiring Diagrams

Common questions and answers regarding lathe wiring. Clarifications on wiring components and troubleshooting tips.Many folks wonder about the ins and outs of lathe wiring. Here are some common queries:

| Question | Answer |

|---|---|

| What are the main components? | The main parts are the power supply, switch, motor, and wiring. |

| How do I troubleshoot wiring issues? | Check for loose connections or damaged wires first. |

| Why does my lathe keep shutting off? | It might be overheating or have a short circuit. |

Understanding these questions can save you time and a few headaches. If things get too tangled, remember, it’s okay to ask for help! After all, even a lathe needs a little love now and then.

Conclusion

In summary, an entry-level metal lathe wiring diagram helps you understand how to connect electrical components safely. This knowledge is vital for beginners and ensures your lathe runs smoothly. To get started, study the diagram carefully and follow each step. We encourage you to explore more resources online to deepen your understanding. Happy learning and safe wiring!FAQs

What Are The Essential Components Of An Entry-Level Metal Lathe Wiring Diagram?An entry-level metal lathe wiring diagram shows how to connect the machine. First, you’ll find the power supply, which gives electricity to the lathe. Next, there are wires that go to the motor, making it turn. You also see buttons for starting and stopping the machine. Lastly, there may be safety features for protection.

How Do You Properly Wire The Motor And Control Panel For A Basic Metal Lathe?To wire the motor and control panel for a metal lathe, first unplug the machine. Next, connect the motor wires to the control panel using the right colors. Usually, black is for power, white is for neutral, and green is for ground. Make sure all connections are tight. Finally, plug it back in and test it to see if it works!

What Safety Precautions Should Be Taken When Wiring An Entry-Level Metal Lathe?When wiring a metal lathe, you should first unplug it to stay safe. Use tools with insulated handles to avoid electric shocks. Make sure your hands are dry and wear rubber-soled shoes. Check for any loose wires or damaged parts before turning it on. Always follow the instructions in the manual for the best safety practices.

Are There Standard Color Codes For Wiring In Metal Lathes That Should Be Followed?Yes, there are standard color codes for wiring in metal lathes. These codes help you know which wires are for power, ground, and control. For example, usually, black is for power, green is for ground, and red may be for control. Always check your machine’s manual to be safe and follow the right colors. This way, you can work safely and avoid mistakes!

What Common Wiring Issues Might Arise During The Setup Of An Entry-Level Metal Lathe, And How Can They Be Resolved?When setting up a metal lathe, you might find loose wires or connections. This can cause the machine to work poorly or not at all. Check all connections to make sure they are tight. If wires are damaged, you should replace them. Always turn off power first to stay safe!