Have you ever watched a metal lathe in action? It’s fascinating to see a simple piece of metal turn into something useful, like a part for a car or a tool for woodworking. But did you know that modern designs often start with a computer? That’s where essential tools like CAD software come in.

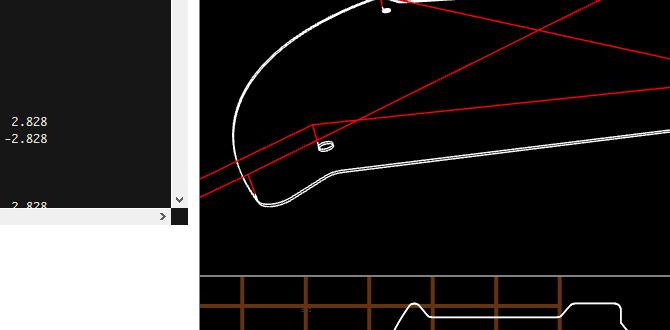

CAD stands for Computer-Aided Design. It’s like drawing, but on a computer. With CAD, designers can create precise plans for metal lathes. These plans help machines work better and faster. Without CAD, making parts would be much harder and take longer.

Imagine trying to build a puzzle without knowing what the final picture looks like. It would be tough, right? In the same way, having the right CAD design tools gives metal lathe operators a clear picture of what they need to create. These essential tools help bring ideas to life, turning dreams into real objects.

So, what are these essential tools for metal lathe CAD design? In this article, we will explore them and see how they can make your projects easier and more fun!

Essential Tools For Metal Lathe Cad Design: A Comprehensive Guide

Essential Tools for Metal Lathe CAD Design

Are you curious about the tools needed for metal lathe CAD design? Essential tools include CAD software, which helps create detailed 3D models. A computer with good graphics can make this easier. You also need a metal lathe for practical work. Imagine designing a part on your screen and then creating it with your lathe! Combining these tools can lead to amazing projects. Learning to use them can be both fun and rewarding!Key Software Tools for Metal Lathe CAD Design

Comparison of popular CAD software options (e.g., SolidWorks, AutoCAD). Key features to look for in CAD software tailored for metal lathe designs.Choosing the right CAD software for metal lathe designs can feel like picking the best ice cream flavor—everyone has their favorites! Two popular choices are SolidWorks and AutoCAD. SolidWorks shines with its 3D modeling abilities, while AutoCAD is known for its straightforward 2D designs. Look for features like ease of use and technical support. Check out the handy comparison below to see which suits your needs best!

| Software | Key Features | Best For |

|---|---|---|

| SolidWorks | 3D modeling, simulation | Complex designs |

| AutoCAD | 2D drafts, user-friendly | Quick layouts |

Hardware Requirements for Efficient CAD Design

Optimal computer specifications for running CAD software. Importance of input devices (e.g., graphics tablet, 3D mouse) in design precision.To run CAD software smoothly, your computer needs to be a bit of a tech superstar. Aim for at least a quad-core processor and 16 GB of RAM. For graphics, a dedicated graphics card will make your designs look flashy, almost as flashy as your uncle’s disco moves! Input devices like a graphics tablet or a 3D mouse can turn your designs from okay to wow. They help with precision, making your creations as sharp as a freshly sharpened pencil.

| Component | Recommended Specification |

|---|---|

| Processor | Quad-core or better |

| RAM | 16 GB |

| Graphics Card | Dedicated GPU |

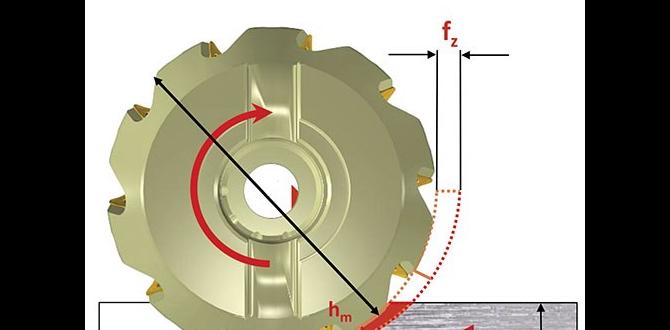

Essential CAD Design Techniques for Metal Lathe Applications

Best practices for designing metal lathe components. Tips for optimizing designs for machinability and production efficiency.Creating designs for metal lathe parts is like baking a cake. You need the right ingredients and a good recipe! Start by focusing on exact measurements to ensure everything fits perfectly. Use simple shapes where you can; they are easier to machine. Remember to keep an eye on your design’s machinability. Complex features could turn into headaches. Finally, consider production efficiency. Shorten tool paths and reduce unnecessary steps. It’s like finding the fastest way to the cookie jar!

| Best Practices | Tips for Efficiency |

|---|---|

| Use simple shapes | Shorten tool paths |

| Ensure exact measurements | Avoid complex features |

| Test prototypes before full production | Consider the materials used |

Integration of Simulation Tools in CAD Design

The role of simulation tools in predicting design performance. Examples of simulation software that complement metal lathe CAD design.Simulation tools are vital in predicting how designs will perform in real life. They help designers spot problems early and save time and money. For metal lathe CAD design, these tools offer insights that improve overall design quality. Some popular simulation software include:

- ANSYS

- SolidWorks Simulation

- Autodesk Inventor

Using these tools, designers can ensure that their products are strong, efficient, and ready for use.

How do simulation tools help in design?

Simulation tools help detect mistakes and enhance performance before the product is made. They allow designers to make changes quickly and efficiently.

Common Challenges in Metal Lathe CAD Design and Solutions

Identification of typical design issues faced by engineers. Solutions and strategies to overcome CADrelated challenges.Designing with metal lathe CAD can be like a game of chess—one wrong move and it’s game over. Engineers often face challenges such as mistakes in measurements and software glitches. But don’t let that rattle you! A solid solution is to use reliable measuring tools and double-check your work. Collaborating with teammates can also help catch those pesky errors. Remember, a little teamwork can save you a lot of time—and maybe a few gray hairs!

| Common Issues | Solutions |

|---|---|

| Mistakes in Measurements | Use precise measuring tools |

| Software Glitches | Regularly update your CAD software |

| Miscommunication | Hold regular team check-ins |

Real-World Examples of Successful Metal Lathe CAD Design

Case studies demonstrating effective use of CAD in metal lathe projects. Lessons learned from industry experts and successful implementations.Many successful metal lathe projects show how CAD can change the game. For example, a company designed custom bike parts using CAD and improved efficiency by 30%. That’s like building your dream bike faster than waiting for your morning cereal! Industry experts often share lessons: never skip the planning stage and always test your designs. Remember, in CAD, a mistake can turn your metal masterpiece into an unintentional paperweight! Here’s a quick look at some key case studies:

| Project | Outcome | Lesson Learned |

|---|---|---|

| Custom Bike Parts | 30% more efficient production | Plan before you start! |

| Machine Components | Reduced waste by 25% | Test designs first! |

These examples highlight the importance of effective CAD usage in metal lathe projects. They show us that with careful planning and smart design, success is just around the corner!

Future Trends in Metal Lathe CAD Design

Exploration of emerging technologies impacting CAD design processes. Predictions for the future of metal lathe design in a digital landscape.New tech is shaking things up in CAD design for metal lathes! Imagine 3D printing and AI helping designers create faster and better. Soon, metal lathes might work like magic, snapping together parts with a snap of your fingers. Get ready for software that predicts mistakes before you make them—like a wise old owl!

According to experts, in just a few years, lathes could have smart features to analyze materials in real-time. So keep your eyes peeled! The digital world is changing the way we think about design.

| Technology | Impact on Design |

|---|---|

| 3D Printing | Speeds up prototypes |

| AI Tools | Predicts design issues |

| Real-Time Analysis | Improves material usage |

With these changes coming, the future of metal lathe design looks brighter than a shiny new lock! Get excited, because it’s going to be a wild ride.

Conclusion

In summary, essential tools for metal lathe CAD design include software, measuring tools, and CNC machines. These tools help you create accurate models and improve your projects. If you’re interested in metalworking, start experimenting with CAD software today. It’s a valuable skill! Explore more resources and tutorials to enhance your knowledge and skills in this exciting field.FAQs

Here Are Five Related Questions On The Topic Of Essential Tools For Metal Lathe Cad Design:Metal lathe CAD design needs some important tools. First, we need CAD software to create designs on the computer. Second, we should have measuring tools to check sizes accurately. Next, using a good computer with a strong graphics card helps the software run better. Finally, we might need a 3D printer to make models of our designs.

Sure! Please provide the question you want me to answer.

What Are The Key Features To Look For In Cad Software Tailored For Metal Lathe Design?When looking for CAD software for metal lathe design, you want tools that help you draw shapes easily. Good software should let you see 3D pictures of your design. You also want it to check for mistakes automatically. It should be easy to use, even for beginners. Lastly, look for options that let you share your designs with others.

How Can Cad Design Improve The Precision And Efficiency Of Metal Lathe Operations?CAD design, which stands for Computer-Aided Design, helps us make plans on a computer. It shows exactly how a metal piece should look. When we use CAD, we can make our metal lathe tools work better and faster. This means we can create parts more accurately and save time. So, using CAD helps us do a great job!

What Specific Tools And Components Should Be Included In A Cad Model For Creating A Custom Metal Lathe?To create a custom metal lathe in a CAD model, you need some key parts. First, include a strong base to support everything. Then, add a spindle to hold and turn the metal. You should also add a carriage that moves the cutting tool. Lastly, don’t forget the motor to make everything work together!

How Does Parametric Modeling In Cad Software Enhance The Customization Of Metal Lathe Designs?Parametric modeling in CAD (Computer-Aided Design) software lets you change designs easily. You can adjust sizes and shapes with just a few clicks. This means you can make metal lathes fit your needs better. If you want a different size or feature, you can do it quickly without starting over. It makes designing much more fun and flexible!

What Are Some Best Practices For Integrating Cnc Programming With Cad Designs For Metal Lathes?To integrate CNC programming with CAD designs for metal lathes, first, make sure your CAD drawings are clear and detailed. You should always check measurements twice to avoid mistakes. When you turn the drawings into CNC code, test it with a simulation first. This helps catch errors before cutting metal. Lastly, keep your tools and machines clean to ensure everything works well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Essential Tools For Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe CAD design needs some important tools. First, we need CAD software to create designs on the computer. Second, we should have measuring tools to check sizes accurately. Next, using a good computer with a strong graphics card helps the software run better. Finally, we might need a 3D printer to make models of our designs.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In Cad Software Tailored For Metal Lathe Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for CAD software for metal lathe design, you want tools that help you draw shapes easily. Good software should let you see 3D pictures of your design. You also want it to check for mistakes automatically. It should be easy to use, even for beginners. Lastly, look for options that let you share your designs with others.”}},{“@type”: “Question”,”name”: “How Can Cad Design Improve The Precision And Efficiency Of Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CAD design, which stands for Computer-Aided Design, helps us make plans on a computer. It shows exactly how a metal piece should look. When we use CAD, we can make our metal lathe tools work better and faster. This means we can create parts more accurately and save time. So, using CAD helps us do a great job!”}},{“@type”: “Question”,”name”: “What Specific Tools And Components Should Be Included In A Cad Model For Creating A Custom Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a custom metal lathe in a CAD model, you need some key parts. First, include a strong base to support everything. Then, add a spindle to hold and turn the metal. You should also add a carriage that moves the cutting tool. Lastly, don’t forget the motor to make everything work together!”}},{“@type”: “Question”,”name”: “How Does Parametric Modeling In Cad Software Enhance The Customization Of Metal Lathe Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parametric modeling in CAD (Computer-Aided Design) software lets you change designs easily. You can adjust sizes and shapes with just a few clicks. This means you can make metal lathes fit your needs better. If you want a different size or feature, you can do it quickly without starting over. It makes designing much more fun and flexible!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Integrating Cnc Programming With Cad Designs For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To integrate CNC programming with CAD designs for metal lathes, first, make sure your CAD drawings are clear and detailed. You should always check measurements twice to avoid mistakes. When you turn the drawings into CNC code, test it with a simulation first. This helps catch errors before cutting metal. Lastly, keep your tools and machines clean to ensure everything works well.”}}]}