Have you ever wondered how machines shape metal? One of the key players in this process is the metal lathe drive system. This tool is more than just a piece of equipment; it’s like the heart of a workshop. Without it, many metal projects would be much harder to complete.

Imagine trying to create a perfect cylinder from a solid block of metal. Sounds tricky, right? That’s where the metal lathe drive system comes in. It turns raw materials into beautiful, precise parts. These systems help craftsmen, engineers, and hobbyists alike.

Did you know that the first lathes appeared over 5,000 years ago? They were simpler back then but just as important. Today’s essential tools have improved significantly. They offer accuracy and efficiency that make a big difference in projects.

This article will explore the essential tools that make up the metal lathe drive system. Whether you are a beginner or a seasoned pro, understanding these tools can transform your work. Let’s dive into this fascinating world together!

Essential Tools For A Metal Lathe Drive System Upgrade

Essential Tools in Metal Lathe Drive Systems

Metal lathe drive systems are vital for turning metal into precise shapes. Key tools include the motor, belts, and gears that power the lathe. Did you know that these components work together to create smooth movement? A well-maintained drive system ensures high-quality cuts and safety. Regularly checking these tools can prevent accidents and improve efficiency. Understanding the essential tools can help hobbyists and professionals alike to maximize their metalworking projects.Understanding Metal Lathe Drive Systems

Definition and function of a metal lathe drive system. Importance in precision machining and manufacturing.A metal lathe drive system helps machines cut and shape metal. It powers the lathe, allowing it to rotate and move tools. This system is vital for precision machining and manufacturing. It ensures each part is made accurately, which is essential for quality products.

- It controls speed and movement.

- It supports fine details in designs.

- It helps reduce waste material.

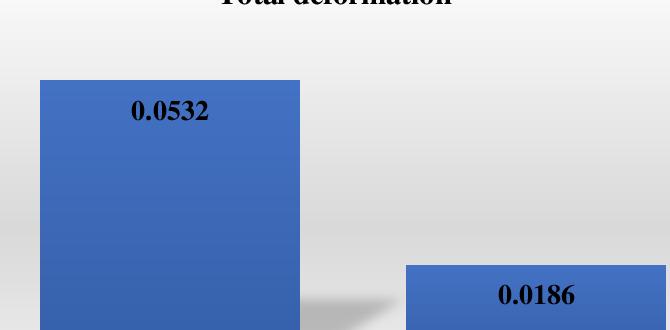

In fact, metal lathe drive systems can improve production efficiency by up to 30%. This means faster and better-made products for everyone!

What is a metal lathe drive system?

A metal lathe drive system powers the equipment to shape metal. It manages the movement and speed needed for precise cuts.

Key Components of Metal Lathe Drive Systems

Discussion of motors and power sources. Importance of pulleys and gears in drive systems. Role of electronic speed controls.Drive systems in metal lathes are like superheroes for your projects. Motors and power sources provide the energy needed to spin that metal like it’s dancing! They come in many forms, but electric ones are the most common.

Now, let’s not forget pulleys and gears. These tiny wonders help transfer power efficiently. Think of them as a friendly neighborhood team working together.

Finally, electronic speed controls are the smart sidekick, making sure everything runs at just the right pace. Too fast? Slow it down! Too slow? Speed it up! It’s like giving your lathe a high-five for a job well done!

| Component | Function |

|---|---|

| Motor | Provides power to the lathe |

| Pulley | Transfers power efficiently |

| Gear | Increases torque and speed |

| Electronic Speed Control | Regulates the motor’s speed |

Essential Tools for Setting Up Drive Systems

List of necessary tools for assembly and installation. Importance of calibration tools for accuracy.Setting up drive systems can feel like a puzzle without all the pieces. You need the right tools to get started. Some essential tools for assembly include wrenches, screwdrivers, and alignment tools. Don’t forget about calibration tools! They help ensure everything lines up perfectly. Proper calibration means your metal lathe runs smoothly, like a well-oiled machine. Here’s a quick list:

| Tool | Purpose |

|---|---|

| Wrenches | Tightening bolts |

| Screwdrivers | Assembling parts |

| Alignment Tools | Ensuring straightness |

| Calibration Tools | Checking accuracy |

Remember, accuracy is the name of the game! A tiny miscalibration can lead to big problems, like creating parts that look like they’re from a funhouse mirror.

Maintenance Tools for Drive Systems

Essential cleaning tools for drive system upkeep. Inspection tools to ensure system functionality.To keep the drive system running well, you need the right cleaning tools. These help remove dust and grime. Here are some essentials:

- Soft brushes for dusting parts

- Lint-free cloths for wiping surfaces

- Cleaning solutions safe for metal

Inspection tools check if everything works. You need tools like:

- Tape measures for size checks

- Calipers to measure gaps

- Multimeters for electrical testing

Keeping these tools handy helps you care for your metal lathe.

Why is regular maintenance important?

Regular maintenance prevents breakdowns and extends the life of your machine.

What cleaning is needed for the drive system?

Use brushes and cloths to keep parts clean and functional.

Common Challenges and Solutions

Typical issues faced with metal lathe drive systems. Effective troubleshooting tools and techniques.Metal lathe drive systems can face some common challenges. These issues may include noise, vibration, and uneven turning. These problems can make work harder. Don’t worry! There are effective tools and techniques to solve these challenges.

- Use a dial indicator to check for alignment.

- Apply lubricant to reduce noise and wear.

- Regularly inspect belts for wear and tear.

- Monitor speed settings to avoid strain.

By using these tips, you can keep your metal lathe running smoothly.

What are common problems with metal lathe drive systems?

Common problems include excessive noise, vibration, and poor surface finish on materials. These issues can result from improper alignment or worn-out components.

Best Practices for Optimal Performance

Tips for maximizing efficiency of drive systems. Recommended routine maintenance practices.To keep your metal lathe drive system running smoothly, check it often. Look for any noisy parts. Replace worn-out pieces before they cause trouble. Lubrication is key; oil those gears to prevent squeaks and protect your machine. Cleaning dirt can help too. A tidy workspace keeps you focused. And hey, consider chatting with other hobbyists! They might share tips you haven’t thought of yet.

| Maintenance Tip | Frequency |

|---|---|

| Inspect Bearings | Weekly |

| Oil Drive System | Every month |

| Clean Work Area | Daily |

| Check Belt Tension | Every few weeks |

Conclusion

In conclusion, understanding the essential tools for a metal lathe drive system is crucial for your projects. These tools help you shape and cut metal accurately. Remember to check your lathe’s manual for specific needs. You can further enhance your skills by practicing regularly and exploring online resources. Dive into metalworking, and have fun creating!FAQs

Sure! Here Are Five Related Questions On The Topic Of Essential Tools For A Metal Lathe Drive System:Here are some important tools for a metal lathe drive system. First, we need a motor. It makes the lathe spin. We also need gears to control the speed. Belts help transfer power from the motor to the lathe. Finally, we should have tools to measure and adjust everything. These tools help us make nice and smooth metal shapes.

Sure! Please ask your question, and I’ll be happy to help!

What Are The Main Components Of A Metal Lathe Drive System And How Do They Work Together?A metal lathe drive system has a few main parts. First, there is a motor that spins to give power. Next, a belt connects the motor to a spindle, which holds the metal piece. When the motor turns, it spins the spindle, allowing us to shape the metal. All parts work together to make precise cuts on the metal.

How Do Different Types Of Drive Systems (Direct Drive Vs. Belt Drive) Affect The Performance And Precision Of A Metal Lathe?The drive system of a metal lathe helps it move and cut metal. A direct drive connects the motor directly to the spindle. This makes it stronger and more precise because there are fewer parts that can slip. A belt drive uses a belt to connect the motor and spindle, which can make it easier to change speeds but might lose some precision. So, for smooth and accurate work, direct drive is usually better.

What Maintenance Procedures Are Critical For Ensuring The Longevity And Efficiency Of A Metal Lathe Drive System?To keep a metal lathe drive system working well, you need to check the oil regularly. Oil makes the parts move smoothly. Cleaning the machine helps too; it keeps dust and dirt away. You should also look for any loose parts and tighten them if needed. Finally, always follow the machine’s guide for special care tips.

How Can Upgrading The Drive System Of A Metal Lathe Improve Machining Capabilities And Productivity?Upgrading the drive system of a metal lathe can help us work faster and better. It makes the machine more powerful, so we can cut through metal easily. This means we finish our projects in less time. With better speed and strength, we can also create more precise parts. Overall, it leads to higher productivity and better results!

What Safety Considerations Should Be Taken Into Account When Working With The Drive System Of A Metal Lathe?When working with the drive system of a metal lathe, you should be careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Make sure the machine is off before adjusting anything. Lastly, tie back long hair and don’t wear loose clothes to stay safe.