Have you ever wondered how metal objects get their perfect shapes? The secret often lies in the essential tools metal lathe pulley. These tools are like magic wands for metalworkers. They help turn blocks of metal into beautiful, precise parts. Imagine making your own toy car wheels or custom tools in your garage!

Many people think that working with metal is just for experts. But with the right tools, anyone can become a metal craftsman. Starting with a metal lathe pulley can make your journey easier. It provides the needed power and control to create amazing projects.

Did you know that many machines depend on pulleys to work smoothly? They help move heavy loads with ease. This simple yet clever invention has a history that dates back thousands of years!

As you explore the fascinating world of metalworking, keep an eye on essential tools, especially the metal lathe pulley. They could be your first step towards creating something truly special!

Essential Tools For Metal Lathe Pulley Operations

Essential Tools for Metal Lathe Pulley

A metal lathe pulley is crucial for machine operation. It helps control speed and torque for precision work. Without the right tools, a lathe can be tricky to use. Did you know that a good pulley can make your projects smoother? It’s true! Quality pulleys enhance efficiency, reduce wear, and ensure safety. Choosing the right tools can improve your metalworking skills. Are you ready to transform your lathe experience with essential pulleys?Understanding Metal Lathe Pulley Systems

Definition of metal lathe pulley systems. Importance of pulleys in lathe operation.Pulleys in metal lathes are like the fun little sidekicks to the hardworking main character! They help adjust the speed of the lathe by transferring power from the motor to the spindle. This makes sure the tool spins just right for cutting or shaping metal. Without these clever devices, the lathe couldn’t function smoothly. Imagine trying to perform a dance without your partner—pretty tough, right?

| Function | Importance |

|---|---|

| Power Transfer | Essential for smooth operation. |

| Speed Control | Allows for versatile machining. |

| Durability | Helps tools last longer. |

In short, the metal lathe pulley system is crucial for any lathe enthusiast. It ensures everything runs like a well-oiled machine! So, never underestimate your pulleys—they’re the unsung heroes of metalworking.

Essential Tools for Installing Metal Lathe Pulleys

List of tools needed (e.g., wrenches, screwdrivers). Safety equipment to consider.To install metal lathe pulleys, having the right tools is key. Start with a few basic items like wrenches and screwdrivers. They help you tighten and loosen screws easily. Don’t forget a steady hammer—sometimes you just gotta persuadingly tap things into place! Safety is super important, too. Use safety goggles to protect your eyes and gloves to keep your hands safe. Remember, you want to avoid having a “whoops” moment!

| Tools Needed | Safety Equipment |

|---|---|

| Wrenches | Safety Goggles |

| Screwdrivers | Gloves |

| Hammer | Dust Mask (optional) |

Maintenance Tools for Metal Lathe Pulleys

Tools required for routine maintenance (e.g., lubrication, cleaning). Importance of maintenance in prolonging pulley life.Having the right tools for maintenance is key. Regular care helps metal lathe pulleys last longer. You need tools for lubrication and cleaning. Here are some essentials:

- Oil for smooth movement

- Soft cloth for dust removal

- Brush for harder-to-reach areas

- Wrench to tighten parts

When you maintain your lathe, you save money and time. A well-kept pulley runs better and lasts longer. Don’t skip this important step!

What tools are needed for cleaning and lubricating lathe pulleys?

Common tools include: oil, cloth, brush, and wrench. These help keep your lathe working smoothly.

Common Issues and Troubleshooting Tools

Tools to diagnose common pulley problems. Recommended methods for troubleshooting.Fixing pulley problems can be tricky, but having the right tools can make it easy. Start with a good wrench set. It helps tighten loose bolts. A tension gauge measures how tight your belt is, ensuring it works right. Use a caliper to check the size of parts. If you hear strange noises, a stethoscope for machines can listen in. Remember, don’t take your pulley problems too seriously; they might just be “spinning” out of control!

| Tool | Purpose |

|---|---|

| Wrench Set | Tighten bolts |

| Tension Gauge | Check belt tightness |

| Caliper | Measure parts |

| Stethoscope | Ddetect strange noises |

Upgrading Your Metal Lathe Pulley System

Essential tools for upgrades and modifications. Considerations for choosing and installing new pulleys.Upgrading your lathe pulley can be like giving your machine a turbo boost! To start, it’s important to gather the right tools. You’ll need basic ones like wrenches and screwdrivers, as well as special items like a torque wrench. These tools help ensure everything is snug and fits just right.

Choosing new pulleys? Think about size and material, like metal or plastic. Metal is stronger but heavier, while plastic is lighter but may wear out faster. Remember, you want pulleys that keep your lathe running smoothly without skipping a beat.

When it’s time to install, double-check that everything aligns correctly. Nothing says “oops” like a pulley flying off while you’re working. You can avoid that disaster by paying attention! So, roll up those sleeves and get ready for some fun upgrades.

| Tool | Purpose |

|---|---|

| Wrenches | Tightening bolts and screws. |

| Torque Wrench | Ensuring correct tightness. |

| Screwdrivers | Installing and adjusting parts. |

Expert Tips for Working with Metal Lathe Pulleys

Recommended techniques for efficient operation. Best practices to avoid common mistakes.Using metal lathe pulleys can be fun and effective if you know what you’re doing. First, always check for proper alignment. Even a tiny misalignment can cause big problems. Remember to choose the right speed. Too fast, and you might break something. Slow and steady wins the race! Lastly, keep your workspace clean; nobody likes tripping over tools. Use the table below for quick tips:

| Tip | Why It Matters |

|---|---|

| Align properly | A voids breakage! |

| Select right speed | Prevents accidents! |

| Keep it tidy | No more toe stubs! |

Conclusion

In summary, metal lathe pulleys are vital tools for smooth machining. They help control speed and torque, making your work easier. Remember to choose the right size and type for your lathe. You can improve your projects by understanding these tools better. For more tips on metalworking, check out additional resources or guides. Let’s keep learning together!FAQs

What Is The Primary Function Of A Pulley System In A Metal Lathe, And How Does It Improve Performance?A pulley system in a metal lathe helps move the machine’s parts smoothly. It changes the speed and direction of the rotating tools. This makes cutting metal easier and more accurate. With a pulley system, you can finish your work faster and with better results. It helps you work more efficiently!

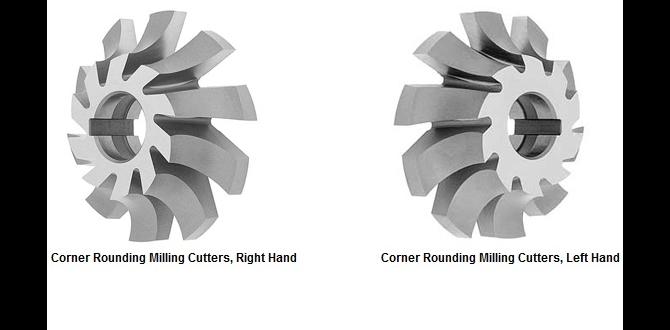

What Types Of Pulleys Are Commonly Used In Metal Lathes, And What Factors Should Be Considered When Selecting Them?Common pulleys used in metal lathes include drive pulleys and idler pulleys. Drive pulleys connect to the motor and help turn the machine. Idler pulleys help change the direction of the belt. When picking a pulley, think about the size, strength, and the type of belt you have. These things help your lathe work well and safely.

How Do You Properly Maintain And Troubleshoot The Pulley System In A Metal Lathe To Ensure Optimal Operation?To keep the pulley system in a metal lathe working well, you should regularly check for wear and tear. Clean the pulleys to remove dust and grime. Look for any loose or broken parts and fix them right away. If you hear strange noises, stop and check for problems. Remember, taking care of it helps the lathe run smoothly!

What Are The Advantages Of Using A Variable Speed Pulley System In Metal Lathes Compared To A Fixed Speed System?Using a variable speed pulley system in metal lathes lets you change the speed easily. This helps you control how fast you work. You can go slower for tricky parts and faster for simple jobs. It makes your work better and helps you finish tasks easier. You have more choices and can do more with the lathe!

How Do You Calculate The Necessary Pulley Ratios For Achieving Specific Spindle Speeds In A Metal Lathe?To find the right pulley ratios for a metal lathe, you start with the speed you want. First, check the motor speed; it usually spins fast. Next, divide the motor speed by the spindle speed you want. This gives you the ratio of how many times the motor turns for each spindle turn. Lastly, use pulleys that match this ratio for the lathe to work correctly.