Have you ever watched a metal lathe in action? It’s like magic as the metal spins and shapes into something new. One key part of this wonderful machine is the quill. But what makes the metal lathe quill so essential?

The quill holds the cutting tool and controls its movement. This simple tool helps create beautiful and precise shapes. Imagine crafting parts for a toy robot or a unique gift. The right quill can make all the difference.

Many people don’t realize how much the quill affects the work. A well-built quill helps you cut smoothly. It also reduces mistakes, making your projects easier. Do you want your metalworking to look professional?

Let’s explore the essential tools related to the metal lathe quill. You’ll learn how each tool works and why it matters. You might even discover some tips to improve your skills. Ready to dive in?

Essential Tools For Metal Lathe Quill Operation Explained

Essential Tools for Metal Lathe Quill

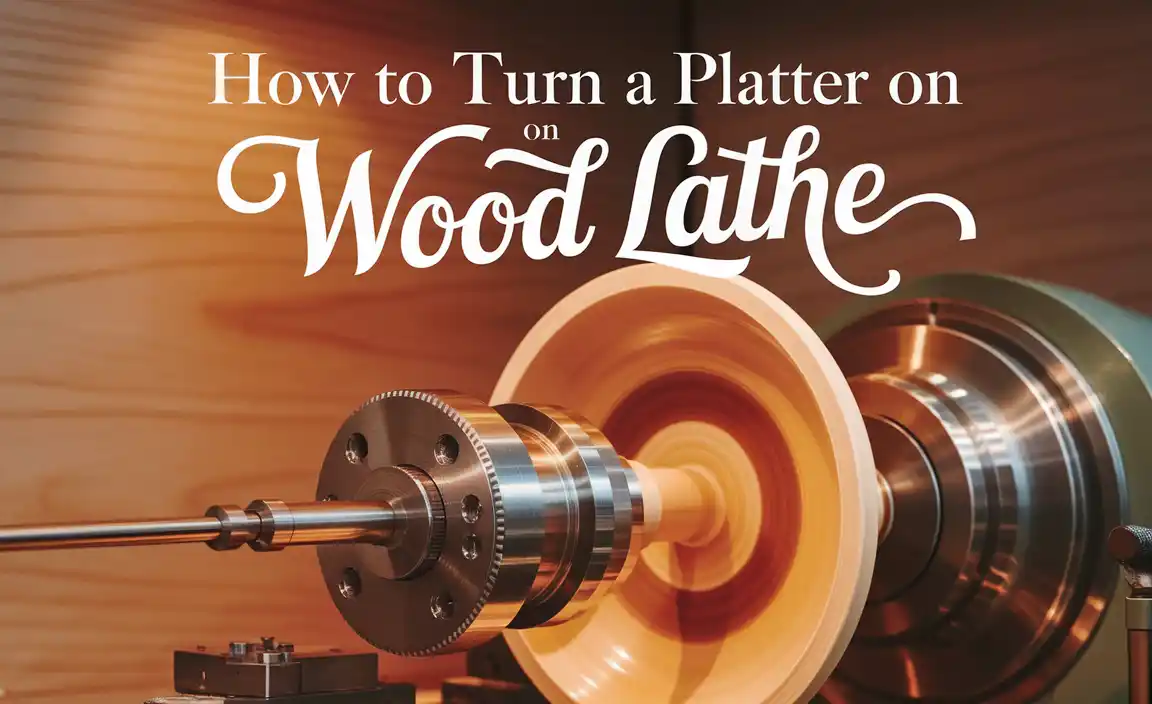

The metal lathe quill is a key part of lathes, allowing precise movements. It holds the cutting tools needed for shaping metal parts. Did you know that different quills can enhance your work’s accuracy? Proper tools make every cut smoother and more efficient. Always choose a quill that fits your lathe. This choice can save time and prevent mistakes. Remember, the right tools can turn a simple project into a masterpiece.Understanding the Metal Lathe Quill

Definition and purpose of the quill in metal lathes. Importance of the quill in precision machining.A metal lathe quill is a crucial part of a metal lathe. It holds the cutting tool and helps it move in and out smoothly. This movement is important for shaping metal pieces accurately. The quill allows for precise depth adjustments, leading to better machining quality. Without it, machinists would struggle to achieve fine details in their work. To summarize:

- Holds cutting tools steady.

- Enables smooth movement.

- Essential for precision.

In fact, a well-functioning quill can improve a project’s accuracy significantly!

What is the importance of the quill in machining?

The quill is important for achieving precision. It helps control how deep the cutting tool goes into the metal. This precision makes parts fit better and last longer.

Essential Tools for Metal Lathe Quill Maintenance

Tools needed for routine quill maintenance and adjustments. Techniques for ensuring longevity and optimal performance.Taking care of your metal lathe quill is essential for smooth operation. You will need a few key tools for routine maintenance. A wrench, screwdrivers, and lubricant are must-haves. Regularly clean the quill and check for cracks. This helps it last longer and work better, keeping it as happy as a kid in a candy store! To make sure your quill stays in top shape, use the right techniques while operating it. Remember, a little bit of care goes a long way!

| Tool | Purpose |

|---|---|

| Wrench | Adjustments |

| Screwdrivers | Tightening screws |

| Lubricant | Reducing friction |

Top Accessories for Metal Lathe Quill Operations

List of popular accessories that enhance quill functionality. Benefits of using these accessories for various machining tasks.Using the right accessories makes metal lathe quill operations easier and more effective. Here are some popular accessories:

- **Drill chucks**: For holding drill bits securely.

- **Tool holders**: They keep cutting tools in place.

- **Live centers**: Help maintain support during machining.

- **Faceplates**: Useful for larger workpieces.

These tools can enhance precision and speed in various tasks. For instance, a drill chuck allows you to switch between different bits quickly. This saves time and produces better results. Overall, having the right tools means better projects.

What are essential accessories for metal lathe quill operations?

Some essential accessories for metal lathe quill operations include drill chucks, tool holders, live centers, and faceplates. These accessories improve accuracy and efficiency in your machining tasks.

Choosing the Right Quill for Your Metal Lathe

Factors to consider when selecting a quill. Comparison of different types and brands available in the market.Choosing the right quill for your metal lathe is important. Here are some key factors to think about:

- Size: Make sure it fits your lathe.

- Material: Choose durable materials like steel.

- Brand: Some brands are known for quality.

- Price: Find a good balance between cost and quality.

Popular brands include XYZ and ABC, known for their reliable products. Each brand has its own advantages, so compare them to find the best fit for you.

What should I consider when selecting a quill?

Consider size, material, brand quality, and price before buying a quill.

Common Issues and Troubleshooting with Metal Lathe Quills

Frequently encountered problems with quills. Stepbystep troubleshooting guide for common issues.Quills on a metal lathe can face problems. Users often deal with issues like jamming, uneven cutting, or improper alignment. Understanding these challenges is key to smooth operation.

Here’s a simple troubleshooting guide:

- Check for Jamming: Ensure there are no obstructions.

- Adjust Alignment: Make sure the quill is set properly.

- Inspect Cutting Tools: Replace worn-out bits for better performance.

What are the most common issues with lathe quills?

Common issues include jamming, misalignment, and wear and tear on cutting tools.

How can I fix a jamming issue?

Remove any debris and make sure the quill is clear. Regular maintenance helps prevent jamming.

Safety Practices When Using a Metal Lathe Quill

Essential safety tools and gear for operation. Best practices to minimize risks and ensure safety during use.Using a metal lathe quill safely is no laughing matter, but a little humor helps! Always wear your safety goggles and ear protection to keep your peepers and ears intact. Use gloves when handling materials, but avoid loose clothing that might get caught. Make sure your workspace is clean, or it could turn into a disaster zone! Here’s a simple table of tools to keep nearby for safe operations:

| Safety Tool | Purpose |

|---|---|

| Safety Goggles | Protect eyes from flying debris |

| Ear Protection | Reduce loud machine noise |

| Gloves | Shield hands from sharp edges |

Following these best practices can help you minimize risks and stay safe. Remember, safety first means you’ll get to see another day of tinkering!

Advanced Techniques for Enhancing Quill Performance

Tips and tricks for skilled machinists to maximize quill efficiency. Techniques for complex machining operations involving the quill.Enhancing quill performance can boost your machining tasks. Start by checking the quill’s alignment. A well-aligned quill improves accuracy. Use light cuts for complex operations. This reduces stress on the tool, enhancing durability. Experiment with different feeds and speeds. Each material responds differently, so find what works best. Regularly clean and lubricate the quill. Proper maintenance prevents wear and keeps it working smoothly.

What tips can improve quill performance?

Align the quill, use light cuts, and maintain regularly. These simple steps lead to better results and longer tool life.

Quick Tips

- Check alignment often.

- Test various speeds.

- Keep it clean and lubricated.

Conclusion

In summary, the essential tools for a metal lathe quill include a steady hand, precise measuring tools, and quality cutting bits. These tools help you achieve accuracy and smooth finishes in your projects. To improve your skills, practice regularly and explore more resources. Keep learning and experimenting with your lathe to create amazing metalwork!FAQs

Sure! Here Are Five Related Questions About Essential Tools For A Metal Lathe Quill:Sure! Here are five important tools you need for a metal lathe quill. First, a drill chuck holds your drill bit tightly. Second, a live center helps make smooth holes by spinning with your work. Third, a tool holder keeps cutting tools steady as we work. Fourth, a taper attachment helps shape parts correctly. Lastly, a measuring tool is important to make sure everything is the right size!

Sure! Just go ahead and ask your question, and I’ll be happy to help you with it!

What Are The Primary Components Of A Metal Lathe Quill, And How Do They Function Together?A metal lathe quill has a few key parts. It usually includes a sleeve, a spindle, and a handle. The sleeve holds the tool in place, while the spindle turns the tool. When you turn the handle, it moves the sleeve in and out. Together, they help you shape metal by moving the cutting tool smoothly.

What Are The Essential Tools Required For Effectively Operating A Metal Lathe Quill During Machining Processes?To operate a metal lathe quill, you need some important tools. First, you need a steady cutting tool that shapes the metal. Next, you’ll want a tool holder to keep it safe and steady. A good measuring tool, like calipers, helps you check sizes. Lastly, we need a chuck key to hold and change the bits on the lathe!

How Do Different Types Of Cutting Tools Impact The Performance Of A Metal Lathe Quill?Different types of cutting tools can change how well a metal lathe quill works. Some tools are sharp, making clean cuts and smooth surfaces. Others might be dull, which makes rough cuts that take longer. The right tool can help you finish your work faster and easier. Better tools also help your lathe last longer!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Metal Lathe Quill?To keep a metal lathe quill working well, you should clean it regularly. Wipe off dust and chips after each use. You also need to oil the moving parts to keep everything running smoothly. Check for any loose screws and tighten them if needed. Finally, store it in a dry place so it doesn’t rust.

How Can One Select The Right Size And Type Of Quill For Specific Metalworking Projects On A Lathe?To choose the right size and type of quill for metalworking, first, check your lathe’s manual. It tells you the sizes that fit. Next, think about the metal you are using. Softer metals need smaller quills, while harder metals need bigger ones. Finally, practice using different quills to see which works best for your project.