Have you ever watched a skilled machinist create precise metal parts? It’s fascinating! A metal lathe is one of the most essential tools in this process. Among its many features, the threading dial stands out as a key player. Why is that? Well, it helps you cut threads accurately. This is important for making bolts and screws that fit together perfectly.

Imagine you are building a toy robot. You need screws that fit just right. Without the threading dial, achieving that perfect fit would be much harder! Did you know that this small device can improve your work’s quality by a lot? It guides the lathe to cut threads at the right depth and spacing. Understanding how to use a metal lathe threading dial can make all the difference in your projects.

So, let’s dive deeper into this essential tool. You will discover tips and tricks to master the art of threading on a lathe. Are you ready to unlock your creativity with the right tools and knowledge?

Essential Tools For Metal Lathe Threading Dial Operation

Essential Tools for Metal Lathe Threading Dial

Metal lathe threading dials are crucial for precision work. They help you measure and cut threads accurately. Think of trying to fit a puzzle piece. Without the right measurements, it just won’t fit! These dials make threading faster and easier. A fun fact is that using a precise dial can improve your work quality significantly. Whether you’re a beginner or skilled, mastering this tool enhances your metalworking projects and saves time.Understanding the Metal Lathe

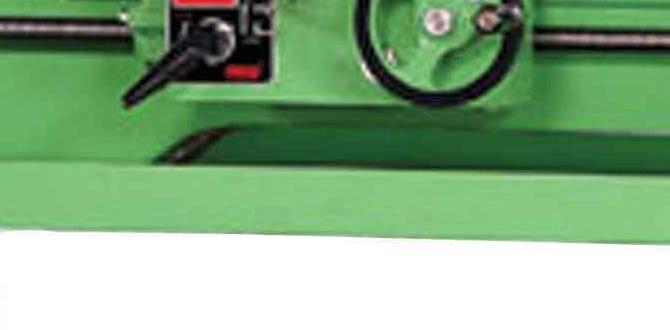

Definition and purpose of a metal lathe. Types of metal lathes commonly used in threading applications.A metal lathe is a machine used to shape metal into different parts. It spins the metal while tools cut and shape it. This helps create precise parts for many machines. Metal lathes come in various types, especially for threading, like:

- Manual lathes

- CNC lathes

- Engine lathes

These machines help in making threaded pieces that fit perfectly together. Understanding how a metal lathe works is essential for anyone interested in machining!

What is the purpose of a metal lathe?

The main purpose of a metal lathe is to turn raw metal into specific shapes or sizes. It supports various projects, from auto parts to small gadgets.

What are the common types of metal lathes used?

- Manual Lathes: Simple and easy to control.

- CNC Lathes: Automated for precise designs.

- Engine Lathes: Versatile for many tasks.

The Importance of a Threading Dial

Function and benefits of a threading dial. How a threading dial improves precision in metalworking.A threading dial is like a superhero for metalworkers! It helps you make perfect threads on metal pieces. By showing where to start and stop, it ensures everything is just right. Better precision means less waste and more success. Imagine trying to bake a cake without a timer—chaos! With a threading dial, metalworking becomes smoother and easier.

| Benefits of a Threading Dial |

|---|

| Improves precision |

| Reduces waste |

| Saves time |

Remember, precision in metalworking is key! A good threading dial turns your lathe into a trusty sidekick. With it, every twist leads to success, making your projects shine like stars in the night sky.

Choosing the Right Threading Dial

What to consider when selecting a threading dial. Comparison of manual vs. electronic threading dials.Picking the best threading dial is key for smooth work. First, look at the size and type you need. Will you choose a manual dial or an electronic one? Each has its perks. A manual dial gives you direct control. It is great for beginners. An electronic dial offers accuracy and speed, perfect for complex tasks. Think about what fits your projects best.

- Manual Dials: Simple and easy to use.

- Electronic Dials: More precise with digital readings.

What should I consider when selecting a threading dial?

You should look for size, ease of use, and accuracy. Choose one that matches your metal lathe. Also, take note of durability.

Setup and Calibration Techniques

Steps for properly setting up a metal lathe for threading. Calibration tips for ensuring accurate measurements.Setting up a metal lathe for threading is like preparing for a dance recital—you need the right moves to stay in sync! First, ensure the lathe is on a stable surface. Leveling it helps avoid wobbles. Next, snug the threading dial into place; it shouldn’t be loose like a pair of old shoelaces. Calibration is key! Use a reliable gauge to check measurements. Remember, accurate numbers equal smooth threads. Follow these steps and you’ll thread like a pro!

| Step | Description |

|---|---|

| 1 | Ensure the lathe is stable |

| 2 | Secure the threading dial |

| 3 | Calibrate with a reliable gauge |

Safety Precautions During Operation

Essential safety gear for metalworking. Common hazards and how to avoid them while using a lathe.Working with a metal lathe can be a bit like playing with a dragon—incredibly fun, but also dangerous! Always wear essential safety gear like gloves, goggles, and ear protection. These items act like a superhero suit. They’ll protect you from flying metal shavings and loud noises. Common hazards include getting caught in moving parts or inhaling dust. Avoid these situations by keeping your hands away from the lathe’s spinning area and ensuring proper ventilation.

| Safety Gear | Purpose |

|---|---|

| Goggles | Protects eyes from debris |

| Gloves | Prevents cuts and scrapes |

| Earmuffs | Reduces noise levels |

Remember, safety first! Like your grandma always says, “Better safe than sorry!”

Common Troubleshooting Tips

Typical issues encountered while threading. Solutions for improving threading quality and accuracy.Threading on a lathe can be tricky. Typical problems include poor thread quality and incorrect sizes. This can happen due to tool wear or improper settings. To fix these issues, follow these tips:

- Check and replace worn tools.

- Adjust the threading dial for better alignment.

- Use proper speeds and feeds for your material.

- Regularly clean the tool and work area.

By paying attention to these details, you can improve threading quality and accuracy.

What can I do if my threads are not aligning correctly?

Ensure the threading dial is set correctly and check the tool for signs of wear.

How can I achieve better accuracy in threading?

Use the correct settings and make sure the lathe is calibrated properly.

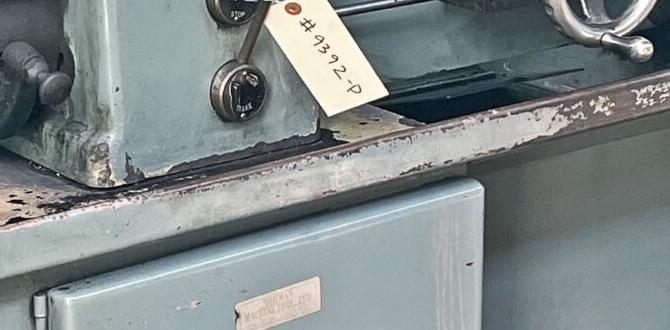

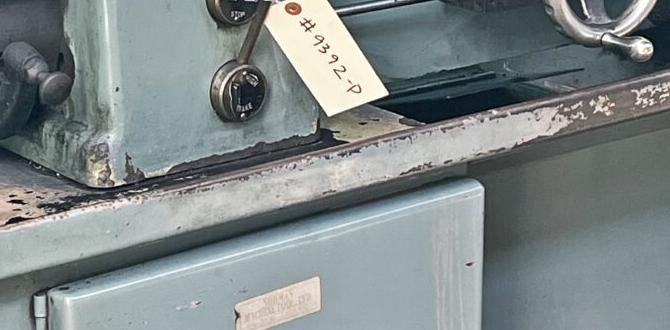

Maintenance Best Practices for Longevity

Routine maintenance tasks for metal lathes and threading dials. Signs of wear and tear to look out for.Keeping your metal lathe and threading dial in tip-top shape is like feeding a pet; they need love too! Regular maintenance tasks include cleaning, oiling, and checking for wear. Notice any strange sounds? That might mean trouble. Look for signs like worn gears or loose parts. Address these issues early, and your tools will thank you by working longer. Remember: a happy lathe makes smooth threads!

| Maintenance Task | Signs of Wear |

|---|---|

| Clean regularly | Loose parts |

| Oil moving parts | Strange noises |

| Check for alignment | Worn gears |

Advanced Techniques for Experienced Users

Exploring complex threading methods and patterns. Tips for maximizing efficiency and output in threading projects.Threading can be quite a ride for seasoned users. You can dive into complex methods to make your projects stand out. Think about using multi-start threads for cool designs! These patterns feel fancy but they’re just *sewing* metal together differently.

To boost your threading projects, *efficiency* is key. This means setting the perfect speed to keep your machine happy, and your output shiny. Remember, a well-timed cut beats a race between gears any day. Trust us, your lathe will thank you!

| Technique | Tip |

|---|---|

| Multi-start threading | Try various patterns for creative outcomes! |

| Proper speed settings | Adjust to avoid snags and maximize smoothness. |

Conclusion

In conclusion, a threading dial is an essential tool for using a metal lathe. It helps you create precise threads easily. Understanding how to use it can improve your projects greatly. If you’re ready to try threading, gather your tools and practice. Don’t forget to explore more about metal lathes and threading techniques for better results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Essential Tools For Metal Lathe Threading Dials:Sure! Here are five important tools for using a metal lathe and its threading dials. First, you’ll need a good ruler or caliper to measure lengths. Next, a threading tool helps cut the right shape into the metal. You will also want a dial indicator to check the smoothness of your work. Finally, have a good set of wrenches to tighten and adjust everything. Using these tools will help you create cool metal items!

Sure! Just let me know what the question is, and I’ll provide a short and simple answer for you.

What Is The Primary Purpose Of A Threading Dial On A Metal Lathe?The primary purpose of a threading dial on a metal lathe is to help you make threads on metal pieces. It shows where to stop the machine when cutting. This makes sure the threads are even and the right size. You turn the dial to the correct number, then start cutting. This tool makes your work easier and more accurate!

How Does The Threading Dial Aid In Achieving Accurate Thread Patterns During Machining?The threading dial helps you create clear and even threads on metal. It shows you the right points to move the tool when cutting. You can watch the numbers on the dial to know when to start and stop. This way, you avoid mistakes and get nice, straight threads every time.

What Are The Key Differences Between A Manual And An Automatic Threading Dial In Metal Lathes?A manual threading dial requires you to move it by hand. You decide when to start and stop the thread. An automatic threading dial moves on its own. It makes threads faster and can be more precise. So, with a manual dial, you do more work, but with an automatic one, it’s easier for you.

Which Accessories Or Tools Should Be Used In Conjunction With A Threading Dial For Optimal Threading Results?To get the best results with a threading dial, you should use a few helpful tools. First, use a sharp cutting tool to make clean threads. A tool rest can help keep your work steady. You might also need a ruler or caliper to measure your threads. Finally, keep your machine clean and well-oiled for smooth operation!

What Common Mistakes Should Operators Avoid When Using A Threading Dial On A Metal Lathe?When using a threading dial on a metal lathe, you should avoid a few common mistakes. First, don’t forget to align the threading dial properly before starting. This helps you cut threads accurately. Also, make sure the machine is set to the right speed. If you go too fast, you could break the tool or ruin the workpiece. Finally, always keep an eye on the threading dial to ensure it matches the right numbers as you go.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Essential Tools For Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five important tools for using a metal lathe and its threading dials. First, you’ll need a good ruler or caliper to measure lengths. Next, a threading tool helps cut the right shape into the metal. You will also want a dial indicator to check the smoothness of your work. Finally, have a good set of wrenches to tighten and adjust everything. Using these tools will help you create cool metal items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what the question is, and I’ll provide a short and simple answer for you.”}},{“@type”: “Question”,”name”: “What Is The Primary Purpose Of A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The primary purpose of a threading dial on a metal lathe is to help you make threads on metal pieces. It shows where to stop the machine when cutting. This makes sure the threads are even and the right size. You turn the dial to the correct number, then start cutting. This tool makes your work easier and more accurate!”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Aid In Achieving Accurate Thread Patterns During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you create clear and even threads on metal. It shows you the right points to move the tool when cutting. You can watch the numbers on the dial to know when to start and stop. This way, you avoid mistakes and get nice, straight threads every time.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Manual And An Automatic Threading Dial In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual threading dial requires you to move it by hand. You decide when to start and stop the thread. An automatic threading dial moves on its own. It makes threads faster and can be more precise. So, with a manual dial, you do more work, but with an automatic one, it’s easier for you.”}},{“@type”: “Question”,”name”: “Which Accessories Or Tools Should Be Used In Conjunction With A Threading Dial For Optimal Threading Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get the best results with a threading dial, you should use a few helpful tools. First, use a sharp cutting tool to make clean threads. A tool rest can help keep your work steady. You might also need a ruler or caliper to measure your threads. Finally, keep your machine clean and well-oiled for smooth operation!”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Operators Avoid When Using A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial on a metal lathe, you should avoid a few common mistakes. First, don’t forget to align the threading dial properly before starting. This helps you cut threads accurately. Also, make sure the machine is set to the right speed. If you go too fast, you could break the tool or ruin the workpiece. Finally, always keep an eye on the threading dial to ensure it matches the right numbers as you go.”}}]}