Have you ever wondered how factories make metals smooth and shiny? One method they use is called face milling with wiper inserts. This technique helps cut materials efficiently and leaves a great finish.

Picture this: a massive machine spinning fast while cutting metal. It sounds cool, right? This machine uses special tools called wiper inserts. These inserts are like tiny knives that clean the surface perfectly as they work.

Why are wiper inserts so important? They save time and money. With these tools, workers can create high-quality parts without spending hours on finishing. Isn’t it amazing how technology can make tasks simpler?

In this article, we will explore face milling with wiper inserts. You’ll learn how they work and why they matter in the world of manufacturing. Get ready to dive into the world of metalworking!

Face Milling With Wiper Inserts: Enhancing Surface Finish

Face milling with wiper inserts can dramatically improve machining efficiency. These special tools help achieve smoother surface finishes and tighter tolerances. By using wiper inserts, you reduce the finishing passes, saving time and costs. Have you ever wondered how manufacturers achieve that perfect shine on metal parts? Wiper inserts are key players in that process. They not only enhance the quality but also extend tool life, making them essential in modern machining. Discover the benefits and advantages of this innovative technique.

What is Face Milling?

Definition and purpose of face milling in machining. Key characteristics and applications in various industries.

Face milling is a machining process that shapes materials like metal and plastic. In this process, a cutting tool, often with multiple edges, removes material from a flat surface. The main goals are to create smooth surfaces and precise shapes. Key features include:

- Versatility: Works on various materials.

- High efficiency: Fast material removal.

- Precision: Creates accurate surface finishes.

This technique finds use in industries like automotive, aerospace, and electronics. It helps produce parts such as engine blocks and circuit boards. Face milling is essential for making high-quality products.

What are the benefits of face milling with wiper inserts?

Wiper inserts enhance surface finishes and reduce machining time, offering big advantages in manufacturing.

Understanding Wiper Inserts

Definition of wiper inserts and their role in face milling. Comparison of wiper inserts with standard inserts.

Wiper inserts are special cutting tools used in face milling. They help create a smooth surface on materials. Their unique shape allows them to finish edges better than regular inserts. This means they produce less roughness and finish jobs faster. Here’s how they compare to standard inserts:

- Surface Finish: Wiper inserts give a smoother finish.

- Speed: They can work quicker during operations.

- Durability: Wiper inserts last longer due to their design.

In essence, wiper inserts are valuable allies in making tasks easier and results better in milling projects.

Why use wiper inserts in milling?

Wiper inserts improve production efficiency. They reduce the number of steps needed to achieve a perfect surface. This saves time and money!

Benefits of Using Wiper Inserts

Enhanced surface finish quality in machining. Improved productivity and efficiency in operations.

Using wiper inserts in face milling has amazing benefits. They create a smoother surface finish. This means parts look nicer and have better quality. Wiper inserts also boost productivity. They help machines run faster and use less energy. This means more work gets done quickly. In short, these inserts improve the whole machining process.

- Enhanced surface finish quality: Smoother and more attractive parts.

- Improved productivity: Faster machining and less energy use.

Why are wiper inserts beneficial in machining?

Wiper inserts provide a better surface finish and increase efficiency. They do not just make things look good; they help machines work faster and save energy.

Choosing the Right Wiper Inserts

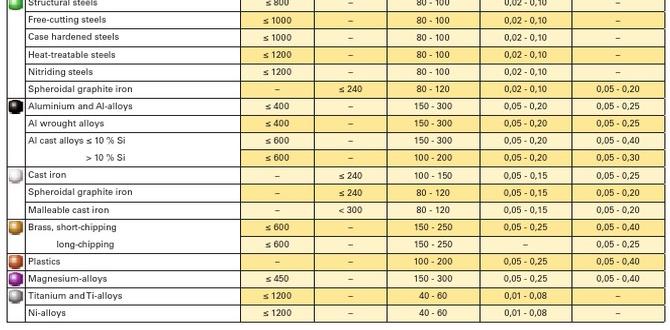

Factors to consider: material, geometry, and coating. Compatibility with various face milling machines and conditions.

Selecting the right wiper inserts can make your face milling work smoother than butter on toast. First, think about the material of the inserts. Harder materials usually last longer. Next is the geometry. Some designs tackle tough spots better than others! Don’t forget the coating. A good coating can help reduce wear, like wearing a raincoat on a drizzly day.

| Factor | Consideration | Impact |

|---|---|---|

| Material | Choose harder inserts | Longer life |

| Geometry | Pick designs for tough spots | Efficient cutting |

| Coating | Use protective coatings | Reduced wear |

Lastly, check compatibility with your milling machine. Some inserts fit better in certain setups, like how peanut butter likes jelly. Consider all these factors so your face milling job goes off without a hitch!

Setup and Operation Best Practices

Recommended setup procedures for optimal performance. Tips for adjusting parameters such as feed rate and cutting speed.

For top-notch face milling with wiper inserts, follow these setup steps. First, ensure your machine is clean; dust can muck up your performance. Check your wiper inserts. They should be sharp, like your mom’s favorite knife! Accurate adjustment of feed rate and cutting speed is key. Use a table like this to guide you:

| Parameter | Recommended Value |

|---|---|

| Feed Rate | 0.1 – 0.3 mm/rev |

| Cutting Speed | 100 – 300 m/min |

Remember, adjustments can be your best friends. Play around with these numbers, like a chef adding spice to a dish. The right combo can make a world of difference!

Common Challenges and Solutions

Identification of common issues faced during face milling with wiper inserts. Effective troubleshooting techniques and solutions.

Face milling with wiper inserts can be as tricky as finding a needle in a haystack. Common issues include poor surface finish and tool wear, which can feel like a bad hair day for your machine. To tackle these problems, first, check cutting speed and feed rate. Adjusting these can make a big difference. Keep an eye on the cutting edge to prevent premature wear. Remember, even machines need some pampering!

| Common Issue | Possible Solution |

|---|---|

| Poor Surface Finish | Adjust cutting speed and feed rate |

| Tool Wear | Monitor the cutting edge regularly |

Advanced Techniques in Face Milling with Wiper Inserts

Strategies for maximizing tool life and performance. Innovations in tool design and machining processes.

Maximizing tool life and performance starts with choosing the right wiper inserts. These little guys can make a big difference. By picking the correct cutting speeds and feed rates, you can help your tools last longer—like the difference between a marathon runner and a sprinter! Innovations in tool design, like improved coatings, can also boost performance. Think of them as superhero capes for your inserts! A well-designed process can save time, money, and headaches.

| Strategy | Description |

|---|---|

| Optimal Cutting Speed | Choosing the right speed reduces wear. |

| Innovative Coatings | Help tools resist heat and friction. |

| Regular Maintenance | Check tools often for longer life. |

Case Studies and Real-World Applications

Examples of successful implementations in different industries. Analyzing the impact of wiper inserts on production efficiency.

Many industries use face milling with wiper inserts to boost their productivity. For example, in the automotive sector, manufacturers improved their part quality and reduced waste. The aerospace industry also saw benefits, as wiper inserts helped create lighter and stronger components efficiently.

- Increased production speed

- Better surface finish

- Less material wasted

These changes lead to happier customers and lower costs. A study showed that companies using these tools saved up to 30% on production time.

What are wiper inserts used for?

Wiper inserts are designed to improve surface quality and finish while minimizing cutting forces. They play a vital role in creating high-quality parts with less effort.

Future Trends in Face Milling Technology

Emerging technologies and materials in face milling. Predictions for the future of wiper insert usage in machining.

New technologies are changing face milling fast. Smart robots and advanced materials are becoming popular. Machines can work better and faster now. Wiper inserts are growing too. They help make smooth surfaces. The future looks bright! Here are some exciting trends:

- Better tools with stronger materials.

- Robots that learn for perfect cuts.

- More eco-friendly options to cut waste.

Experts believe these changes will keep improving machining in the coming years.

What are future trends in face milling technology?

Future trends include smarter machines, stronger materials, and eco-friendly options. These will enhance efficiency and quality.

Conclusion

In conclusion, face milling with wiper inserts improves surface quality and increases productivity. These inserts help create smoother finishes while reducing cycle time. You can achieve better results by choosing the right tool and technique. If you want to learn more, read up on different insert types and machining strategies. Experimenting will help you master face milling!

FAQs

Here Are Five Questions Related To Face Milling With Wiper Inserts:

Face milling with wiper inserts is a way to make smooth and flat surfaces on materials. Wiper inserts help remove extra tiny bumps or marks left by cutting tools. You can think of it like using a special tool to erase those bumps. This process helps machines work better and last longer. It’s important for making parts fit together nicely.

Sure! Please provide me with the question you would like me to answer.

What Are The Primary Advantages Of Using Wiper Inserts In Face Milling Operations Compared To Traditional Inserts?

Wiper inserts help make smoother surfaces when we cut metal. They can remove more material in one pass, which saves time. Using wiper inserts also means less need for polishing later. This makes our work easier and faster, which is really helpful! Overall, wiper inserts improve the quality of our work.

How Do Wiper Inserts Affect The Surface Finish And Dimensional Accuracy Of The Machined Part In Face Milling?

Wiper inserts help make a smooth surface on the part we are machining. They shape the metal as it’s cut, which gives a better finish. This means fewer bumps and scratches. Wiper inserts also keep the part the right size, so it matches our plans better. We use them to get a neat, precise result.

What Materials Are Typically Used For Wiper Inserts, And How Do They Impact Performance During Cutting Operations?

Wiper inserts are usually made from materials like carbide and ceramic. Carbide is strong and lasts a long time, which helps cut better. Ceramic is really hard and works well for fast cutting. The materials help you get smooth and neat cuts when you work. Good materials mean less time fixing mistakes!

What Factors Should Be Considered When Selecting The Appropriate Wiper Insert Geometry For A Specific Face Milling Application?

When picking a wiper insert for face milling, you should think about a few key things. First, consider the material you will cut, like steel or aluminum. Next, look at how smooth you want the surface to be. The shape of the insert is also important; some shapes make better finishes than others. Finally, pay attention to the speed of the machine. Choosing the right factors helps you get great results!

How Can The Cutting Speed And Feed Rate Be Optimized When Using Wiper Inserts To Achieve The Best Results In Face Milling?

To get the best results with wiper inserts in face milling, we need to adjust cutting speed and feed rate. Start by using a medium cutting speed. If the tool feels too hot or wears out quickly, lower the speed. Next, set a steady feed rate. If you feed too fast, the cut might be rough, so find a speed that gives a smooth finish. Always test and tweak settings to find what works best for your specific job.