Imagine you have a metal lathe at home. You want to create amazing projects, but how do you make precise threads? This is where the threading dial comes into play. A for home use metal lathe threading dial helps you achieve accuracy with ease.

Have you ever struggled to line things up just right? It’s frustrating, isn’t it? A threading dial makes this process simpler and faster. You can focus on your creativity instead of worrying about measurements.

Did you know that even small mistakes can lead to big issues in threading? With the right tools, like a threading dial, you can improve your skills quickly. So, whether you’re a beginner or a seasoned pro, this tool can change the way you work.

In this article, we will explore how a for home use metal lathe threading dial can benefit your projects. Get ready to discover tips and tricks that will make your home lathe experience more enjoyable and successful!

For Home Use Metal Lathe Threading Dial: A Comprehensive Guide

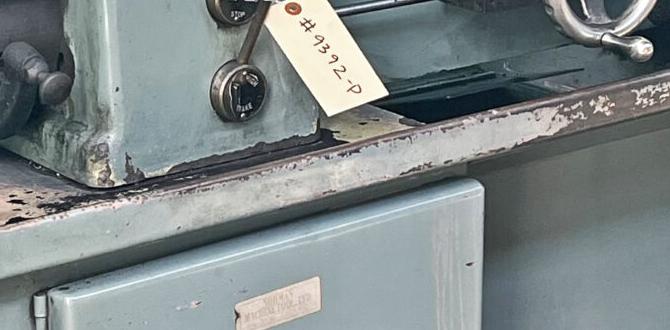

For Home Use Metal Lathe Threading Dial

The threading dial is a crucial tool for home metal lathe users. It helps in making precise threads, which are essential for many projects. With a threading dial, you can create threads accurately and quickly, saving time and effort. Did you know that using a threading dial can improve your lathe work significantly? It allows you to achieve consistent thread pitches. So, if you’re building or repairing something, this tool can be a game changer!Understanding Metal Lathe Threading Dials

Definition and purpose of threading dials. Importance of precision in threading operations.A threading dial helps you create precise threads on your metal lathe. Its main purpose is to guide the tool for accurate cutting. Without it, threading can be messy and uneven. Precision is essential because small mistakes can ruin your work. Just a fraction off can mean the difference between a strong product and a weak one. This tool helps you stay on track.

What is the importance of precision in threading?

Precision is vital in threading operations because it ensures that parts fit together perfectly. This prevents problems in assembly and improves overall quality.

- Threading dials help achieve accurate measurements.

- They enable consistent depth in cuts.

- Good precision reduces waste of materials.

Key Features to Consider When Choosing a Threading Dial

Accuracy and measurement standards. Durability and material quality.Choosing a threading dial for your metal lathe should focus on two important features: accuracy and durability. You need to know if it measures correctly. This helps you create smooth threads. Check the material quality, too. Strong materials last longer and work better.

- Accuracy: Look for dials with clear markings.

- Durability: Choose metal dials over plastic for longer life.

What should I look for in a threading dial?

Look for clear measurements and strong materials. This ensures you get great results every time.

Installation and Setup of Threading Dials

Stepbystep guide on installing a threading dial. Common mistakes to avoid during setup.Setting up a threading dial can seem tricky, but follow these simple steps to make it easier. First, securely mount the dial on your lathe. Next, align it with the machine’s spindle—just like aligning a pizza slice with your plate! Avoid common mistakes like not securing the dial tightly or misreading the instructions. Remember, if you feel confused, check the manual! Your threading dial will thank you later.

| Step | Action |

|---|---|

| 1 | Securely mount the threading dial |

| 2 | Align the dial with the spindle |

| 3 | Double-check for tightness |

| 4 | Read the manual for clarifications |

Just remember, when in doubt, consult the manual or a fellow metal lathe enthusiast. Happy threading!

How to Use a Threading Dial Effectively

Techniques for accurate threading with dials. Tips for troubleshooting common issues during operation.Using a threading dial is key for neat threads on your projects. Start by lining up the threading dial correctly. Turn it slowly to make sure your cuts are precise. If you encounter problems, check these tips:

- Ensure the dial is clean.

- Adjust the tool height for better cuts.

- Pay attention to spindle speed.

Refining these techniques can improve your results!

What should I do if my threading dial is not working?

Check the alignment and ensure it’s free from debris. If it still fails, recalibrate or seek expert help.

Maintenance and Care for Your Threading Dial

Best practices for cleaning and maintaining a threading dial. Signs that indicate the need for repair or replacement.Keeping your threading dial clean is very important. Dirt can cause it to work poorly. Here are some tips for maintenance:

- Wipe it down with a soft cloth regularly.

- Use light oil to keep it running smoothly.

- Check for rust or damage often.

If you notice any issues, like misalignment or sticking parts, it may need repair. Don’t wait too long. A well-maintained threading dial lasts longer and works better!

What are signs my threading dial needs repair?

Watch for any strange noises or poor alignment. If your dial moves slowly, it could be time for repair or replacement.

Comparing Popular Threading Dial Brands for Home Use

Review of leading brands in the market. Customer feedback and expert recommendations.Finding the best threading dial can feel like searching for a needle in a haystack. So, let’s compare the top brands out there! One popular choice is the Grizzly G4017. It’s praised for durability and ease of use. Customers say it smooths out threading like butter. Then there’s the Jet JWL-1442VS, loved for its precision. Users appreciate its accurate readings. Lastly, the PM-1440GT gets thumbs up from experts for its reliability. Here’s a quick table to summarize:

| Brand | Features | Customer Feedback |

|---|---|---|

| Grizzly G4017 | Durable, Easy to Use | Smooth threading |

| Jet JWL-1442VS | Precise | Accurate readings |

| PM-1440GT | Reliable | Expert recommendation |

Choosing a threading dial isn’t boring; it’s an adventure! Many home users appreciate how these dials transform their projects. So gear up and thread away like a pro!

Cost Analysis: Investing in a Quality Threading Dial

Breakdown of pricing for various threading dials. Factors that affect the cost and value for money.Buying a good threading dial can be a smart choice for your home lathe. Prices can vary a lot, depending on quality and features. Generally, you might find them ranging from $50 to $300. Consider these key factors when looking to invest:

- Material Quality: Stronger materials often last longer.

- Brand Reputation: Trusted brands may offer better reliability.

- Additional Features: Extra features can enhance usability.

Overall, investing in a quality threading dial can save you time and effort!

How much should I spend on a threading dial?

You should expect to spend between $50 and $300 for a good threading dial. Choose one that fits your budget and needs.

Real-Life Applications and Projects Using Threading Dials

Examples of projects that benefit from precise threading. Community success stories and innovative uses of threading dials.Threading dials are like the secret sauce for many fun projects! They help create super fine threads for items like bolts, knobs, and even stylish furniture pieces. Think of a community project where neighbors join to build birdhouses. Using threading dials makes sure everything fits perfectly! Another cool idea is customizing fishing rods for the perfect catch. Did you know that using a threading dial can make your project 70% more precise? It’s like giving your tools a superpower!

| Project | Benefit |

|---|---|

| Birdhouses | Perfect fit and stability |

| Fishing Rods | Enhanced accuracy for the perfect catch |

| Furniture Making | Stylish designs with precise threading |

Conclusion

In conclusion, a metal lathe threading dial is essential for home projects. It helps you make precise threads quickly and easily. With the right lathe, you can create impressive items. Now that you know its importance, consider researching different lathe options or exploring threading techniques. Happy creating!FAQs

Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe Threading Dial For Home Use:Sure! A metal lathe threading dial helps you make threads on metal pieces. It shows you where to start cutting. When you turn the dial, it keeps things lined up perfectly. This tool is useful for anyone who works with metal at home. It makes threading easier and more accurate!

Sure! Please provide the question you would like me to answer.

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Improve The Threading Process?A threading dial on a metal lathe helps you cut threads evenly. It shows you when to move the tool for the next cut. This way, you don’t have to guess and can make precise threads. Using the dial makes your work easier and more accurate. It helps you finish projects faster and with better results.

How Do You Properly Calibrate And Use A Threading Dial On A Home Metal Lathe For Accurate Thread Cutting?To calibrate the threading dial, first turn the lathe on and set it to a low speed. Then, move the tool close to the workpiece and make a mark. Next, turn the threading dial to zero. This helps you keep track of your threads. When you begin cutting, use the numbers on the dial to help you make even turns. Keep an eye on the dial while you work, and adjust as needed.

What Are The Differences Between A Built-In Threading Dial And An External One, And Which Is More Suitable For Home Workshops?A built-in threading dial is part of the machine. You don’t need to attach anything extra. An external threading dial is a separate tool you can add. For home workshops, a built-in thread dial is often better. It saves space and is easier to use.

Can You Troubleshoot Common Issues That Arise While Using A Threading Dial On A Metal Lathe, Such As Misalignment Or Inaccurate Threads?Yes, we can fix common problems with the threading dial on a metal lathe. If your threads don’t line up, check that the dial is set correctly and the lathe is level. If the threads are not accurate, make sure the cutter is sharp and the speed is right. Also, check if you have the right settings for the thread you want to make. If you still have trouble, try adjusting the feeding rate slowly.

What Are Some Recommended Maintenance Practices For Ensuring The Longevity And Accuracy Of A Threading Dial On A Metal Lathe?To keep your threading dial on a metal lathe working well, clean it often. Dust and dirt can make it stick. You should check for any loose screws and tighten them if needed. Lubricate the moving parts lightly to help them slide smoothly. Lastly, store your lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe Threading Dial For Home Use:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe threading dial helps you make threads on metal pieces. It shows you where to start cutting. When you turn the dial, it keeps things lined up perfectly. This tool is useful for anyone who works with metal at home. It makes threading easier and more accurate!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Improve The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you cut threads evenly. It shows you when to move the tool for the next cut. This way, you don’t have to guess and can make precise threads. Using the dial makes your work easier and more accurate. It helps you finish projects faster and with better results.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate And Use A Threading Dial On A Home Metal Lathe For Accurate Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the threading dial, first turn the lathe on and set it to a low speed. Then, move the tool close to the workpiece and make a mark. Next, turn the threading dial to zero. This helps you keep track of your threads. When you begin cutting, use the numbers on the dial to help you make even turns. Keep an eye on the dial while you work, and adjust as needed.”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Built-In Threading Dial And An External One, And Which Is More Suitable For Home Workshops?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A built-in threading dial is part of the machine. You don’t need to attach anything extra. An external threading dial is a separate tool you can add. For home workshops, a built-in thread dial is often better. It saves space and is easier to use.”}},{“@type”: “Question”,”name”: “Can You Troubleshoot Common Issues That Arise While Using A Threading Dial On A Metal Lathe, Such As Misalignment Or Inaccurate Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we can fix common problems with the threading dial on a metal lathe. If your threads don’t line up, check that the dial is set correctly and the lathe is level. If the threads are not accurate, make sure the cutter is sharp and the speed is right. Also, check if you have the right settings for the thread you want to make. If you still have trouble, try adjusting the feeding rate slowly.”}},{“@type”: “Question”,”name”: “What Are Some Recommended Maintenance Practices For Ensuring The Longevity And Accuracy Of A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your threading dial on a metal lathe working well, clean it often. Dust and dirt can make it stick. You should check for any loose screws and tighten them if needed. Lubricate the moving parts lightly to help them slide smoothly. Lastly, store your lathe in a dry place to prevent rust.”}}]}