Do you love tinkering with machines? Many people do! A metal lathe can be an exciting tool for anyone who enjoys crafting. But what if your old lathe could do even more? That’s where a gearhead metal lathe CNC retrofit comes into play.

Imagine taking your ordinary metal lathe and transforming it into a smart machine that can work on its own. Sounds cool, right? With some upgrades, your lathe can make precise cuts and designs, saving you time and effort.

Did you know that retrofitting your metal lathe can turn it into a CNC (Computer Numerical Control) marvel? This upgrade opens up a world of possibilities. You can create stunning projects with amazing accuracy.

Join us as we explore how a gearhead metal lathe CNC retrofit can breathe new life into your workshop. Get ready to discover tips, tricks, and stories from others who took the plunge. Are you ready to unlock your lathe’s full potential?

Gearhead Metal Lathe Cnc Retrofit: Transforming Precision Engineering

Discovering Gearhead Metal Lathe CNC Retrofit

If you love machines and tinkering, gearhead metal lathe CNC retrofit is exciting! This process upgrades traditional lathes for better performance. Imagine transforming basic tools into smart, efficient machines. You’ll learn how to enhance precision and speed in your projects. Did you know a retrofit can save costs compared to buying new equipment? With simple steps, you can dive into this fascinating world. Explore how innovation can reshape your workspace!Understanding Gearhead Metal Lathes

Definition and characteristics of gearhead metal lathes. Advantages over other types of lathes.Gearhead metal lathes are like the superheroes of workshop tools. They have a sturdy design that makes them great for tough jobs. Unlike other lathes, these don’t scramble when faced with heavy metals. Their key features include a powerful gear system for smooth performance and high torque. This means they can handle big jobs with ease. Plus, they’re usually quiet, which is a perk—especially when you’re trying to sneak in some extra work at night without waking the neighbors!

| Advantages | Gearhead Metal Lathes | Other Types of Lathes |

|---|---|---|

| Power | High torque for heavy materials | Less torque, harder to use on heavy metals |

| Ease of Use | Simple gear system | More complex controls |

| Noise | Generally quieter operation | Can be quite loud |

What is CNC Retrofit?

Explanation of CNC retrofitting. Benefits of converting traditional machines to CNC.CNC retrofitting is the process of updating traditional machines with modern computer controls. It makes these machines smarter and more efficient. Turning old machines into CNC machines has many perks:

- Precision: CNC machines are very accurate, reducing mistakes.

- Speed: They work faster than manual machines.

- Flexibility: Users can easily change designs and tasks.

Overall, CNC retrofitting breathes new life into older machines, making them work harder and smarter.

What are the advantages of CNC retrofitting?

There are many benefits to CNC retrofitting. It saves time, improves safety, and helps save money by reducing waste.

Benefits of Gearhead CNC Retrofits

Increased precision and repeatability. Expanded capabilities and versatility in machining.Upgrading to a gearhead CNC retrofit can bring big smiles to your workshop! Why? First, it boosts precision and repeatability, making every cut feel like magic. Imagine crafting parts flawlessly, again and again, like a wizard waving a wand! Second, the retrofit opens up new capabilities. You can tackle different materials and designs, transforming the ordinary into the extraordinary. Your metal lathe will feel like a superhero in a world of boring tools!

| Benefit | Description |

|---|---|

| Increased Precision | Cut parts with extreme accuracy every time. |

| Expanded Capabilities | Work with various materials and new designs. |

Step-by-Step Guide to CNC Retrofitting a Gearhead Lathe

Preparing the lathe for retrofit. Installing CNC components. Configuring software and controls.Get ready to turn your old lathe into a fancy CNC machine! First, remove any unnecessary parts from your lathe. This gives you a clean start. Next, install the CNC components. These pieces are like the brain of your new lathe. Once everything is in place, it’s time to configure the software. Think of it like teaching your lathe a new dance. It needs to know the steps to groove smoothly!

| Step | Description |

|---|---|

| Prepare | Clean out extra parts and dust from the lathe. |

| Install CNC Components | Add motors and controllers to make it smart! |

| Configure Software | Set the program so it knows how to move. |

With these steps, your gearhead lathe will be ready to rock the CNC world!

Common Challenges and Solutions

Identifying possible issues during the retrofit process. Tips for troubleshooting and optimizing performance.Retrofitting a gearhead metal lathe with CNC can feel like solving a puzzle, but it can also come with a few hiccups. Common problems include misaligned parts or poor software connections. Don’t fret! A simple tune-up of settings and checking for loose wires can fix many glitches.

Here are some handy tips:

| Challenge | Solution |

|---|---|

| Misalignment | Check and adjust motor alignment |

| Software Bugs | Update and restart the software |

| Poor Cutting Performance | Adjust feed rates and tool speed |

Remember, even machines have their off days! Keep calm and keep tinkering. Soon enough, you’ll have a metal lathe that runs smoother than a freshly oiled typewriter.

Cost Considerations for Retrofits

Breakdown of potential costs associated with retrofitting. Comparing retrofit costs to purchasing new CNC machines.Retrofitting a CNC machine can be a smart way to save some bucks. First, consider the costs of parts and labor. On average, upgrades can range from a few hundred to several thousand dollars, depending on your machine’s needs. Compare this to buying a new CNC, which can cost anywhere from $10,000 to $100,000. Retrofitting may keep your wallet happy while saving your trusty machine from retirement. Remember, a happy machine means happy projects!

| Cost Item | Estimated Cost |

|---|---|

| Upgrades (Parts) | $500 – $5,000 |

| Labor | $100 – $1,000 |

| New CNC Machine | $10,000 – $100,000 |

Case Studies: Successful Gearhead CNC Retrofits

Examples of successful projects and their outcomes. Insights and lessons learned from experienced retrofitting users.Many impressive gearhead CNC retrofits exist, showcasing how creativity meets engineering. For example, one project transformed an old lathe into a modern marvel. Users reported improved precision and speed, with some even joking they could now “lathe like a boss!” Insights revealed that planning is crucial; understanding the machine’s original flaws helps avoid future mistakes. Next, let’s dig into success stories and lessons learned in the table below:

| Project | Outcome | Lessons Learned |

|---|---|---|

| Old Lathe Upgrade | Increased accuracy by 50% | Plan your steps! |

| Mill-to-Lathe Retrofit | Faster production time | Test everything! |

Future Trends in CNC Technology and Retrofits

Emerging technologies in CNC machining. Predictions for the future of retrofitting metal lathes.The world of CNC technology is buzzing with excitement! New tools like machine learning and robotic arms are on the rise, making CNC machining faster and smarter. Imagine a CNC lathe that learns from its mistakes—talk about a stubborn machine becoming a genius! In the future, retrofitting metal lathes might be as common as swapping out old light bulbs for energy-efficient ones. We might even see more DIY upgrades that turn your trusty lathe into a super-powered machine!

| Trend | Description |

|---|---|

| Automation | Machines working together without much human help! |

| Data Analytics | Using data to make machines more efficient! |

| IoT Integration | Machines talking to each other like a gossiping group! |

Conclusion

In conclusion, retrofitting your gearhead metal lathe with CNC makes it more powerful and precise. You can create amazing projects easily. This upgrade saves time and boosts your skills. If you’re curious, consider looking up guides and tutorials online. Embrace the journey of learning and transforming your lathe into a CNC machine!FAQs

Sure! Here Are Five Related Questions On The Topic Of Gearhead Metal Lathe Cnc Retrofit:Sure! Here are some helpful answers about gearhead metal lathe CNC retrofits. 1. **What is a gearhead metal lathe?** A gearhead metal lathe is a machine that helps shape metal. It spins metal so we can cut or shape it into different parts. 2. **What does CNC mean?** CNC stands for Computer Numerical Control. It means that a computer helps run the machine to make it more accurate. 3. **Why retrofit a lathe?** We retrofit a lathe to add new tools or features. This makes the machine work better and easier. 4. **What tools do I need for retrofitting?** You will need some basic tools like wrenches, screwdrivers, and a computer. These help you take apart and put together the lathe. 5. **Can I do this myself?** Yes! If you follow instructions carefully, you can retrofit a lathe yourself. It might take time, but it’s a fun project!

Sure! Please provide the question you would like me to answer.

What Are The Key Components Needed For Retrofitting A Gearhead Metal Lathe To Cnc?To change a gearhead metal lathe to CNC (Computer Numerical Control), you need a few important parts. First, you need a computer to control everything. Then, you will need motors to move the lathe. You also need special software to tell the machine what to do. Lastly, don’t forget about wiring to connect everything together.

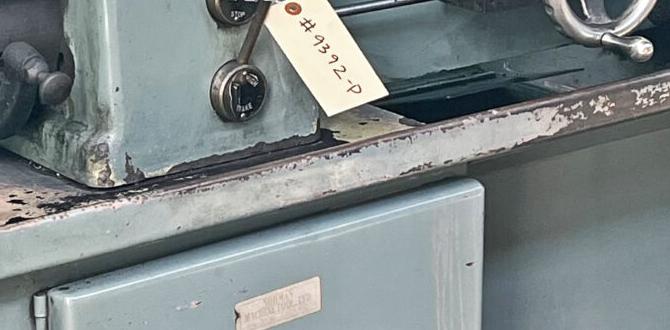

How Can I Determine If My Existing Gearhead Lathe Is Suitable For A Cnc Retrofit?To see if your gearhead lathe can be changed to a CNC (Computer Numerical Control) machine, check a few things. First, look at its size and shape. It should have enough space for new parts. Next, see if it runs smoothly and is in good condition. Lastly, check if it has a solid base since CNC machines need stability. If everything looks good, your lathe may be suitable for a retrofit!

What Software Options Are Available For Controlling A Retrofitted Cnc Gearhead Metal Lathe?You can use special software like LinuxCNC, Mach3, or GRBL to control a CNC lathe. These programs let you tell the machine what to do. They help you move the tools and make shapes from metal. Each option has its own features, so you can choose one that you like best.

What Are The Common Challenges Faced During The Cnc Retrofit Process Of A Gearhead Lathe?When we retrofit a gearhead lathe to use Computer Numerical Control (CNC), we face some challenges. First, we must fit new parts, which can be tricky. Sometimes, the old parts don’t work well with the new technology. Next, we need to make sure the computer understands how to move the lathe properly, which can be complicated. Finally, you may need to learn new ways to operate the machine.

How Can I Ensure The Accuracy And Precision Of My Gearhead Metal Lathe After Retrofitting It To Cnc?To ensure your gearhead metal lathe works well after upgrading to CNC (Computer Numerical Control), you need to check a few things. First, make sure all the parts are tightly secured and looking good. You should regularly calibrate the machine using special tools to verify it cuts in the right places. Clean it often to keep it free of dirt and dust. Finally, test your lathe by making small parts to see if everything is accurate.