Have you ever stood before your metal lathe, wondering if everything was perfectly aligned? Many gearheads face this challenge. Aligning the tailstock is crucial for precision work. A small mistake can lead to big problems in your projects.

Imagine planning a great piece only to find it ruined by misalignment. It can be frustrating, right? But you’re not alone. Tailstock alignment is a common hurdle for many makers.

Did you know that even slight misalignment can change the way your projects turn out? This fact surprises many. Proper alignment can save time, effort, and money.

In this article, we will explore how to effectively align your gearhead metal lathe tailstock. We’ll share tips and tricks that make this task easy and fun. So, let’s dive in and get your lathe working at its best!

Gearhead Metal Lathe Tailstock Alignment: A Comprehensive Guide

Gearhead Metal Lathe Tailstock Alignment

Proper alignment of the tailstock on a metal lathe is crucial for accuracy. Misalignment can lead to poor cuts and uneven surfaces. To check alignment, you can use a dial indicator. It’s surprising how a small adjustment can improve your work. Understanding how to align the tailstock not only helps in achieving perfect cylindrical parts but also boosts your confidence. Imagine creating precise projects that impress everyone! Do you want to level up your metalworking skills?Understanding Tailstock Functionality

Explanation of the tailstock’s role in metal lathing. Importance of proper alignment for precision machining.The tailstock is an important part of a metal lathe. It supports the end of the workpiece while it spins. This support helps keep things straight. Proper alignment of the tailstock is crucial for good results. If it’s off, the workpiece can wobble. This can lead to mistakes and wasted materials. Accurate cuts mean better projects. When the tailstock is aligned right, your work will be precise and neat.

What does a tailstock do in metal lathing?

The tailstock helps to support the workpiece and maintain stability during machining.Why is alignment important?

- Prevents wobbling

- Ensures accurate cuts

- Reduces material waste

Tools Required for Tailstock Alignment

List of essential tools for alignment checks. Recommendations for highquality alignment tools.Aligning the tailstock on your lathe requires some important tools. Here’s what you need:

- A sturdy level to check flatness.

- A caliper for accurate measurements.

- A good dial indicator for precision alignment.

- Alignment bars for easy setup.

- Simple hand tools like wrenches and screwdrivers.

For quality, choose brands like Starrett or Mitutoyo. They make reliable tools that last. Using the right tools helps ensure your lathe runs smoothly and accurately.

What tools do I need for tailstock alignment?

You need a level, caliper, dial indicator, and alignment bars. Good hand tools like wrenches and screwdrivers are also essential.

Step-by-Step Tailstock Alignment Process

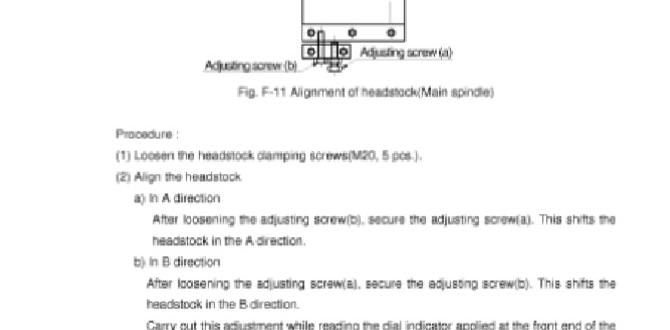

Detailed procedures for aligning the tailstock. Visual aids to assist with the alignment process.Aligning your tailstock is key for precision in your projects. Follow these steps for an easy process:

- Check the lathe bed for levelness. It should be flat.

- Loosen the tailstock clamps. This lets you move it easily.

- Use a dial indicator on the tailstock. This helps measure alignment.

- Adjust the tailstock until the dial shows zero. This means it’s aligned!

- Tighten the clamps back. Make sure everything stays in place.

Visual aids, like diagrams, can make this task easier. Look for videos online showing tailstock alignment. They often have clear steps and tips. You’ll be aligning like a pro in no time!

How do you align a metal lathe tailstock?

To align a metal lathe tailstock, check for flatness, adjust until zero on a dial indicator, and tighten clamps. Use resources like videos or diagrams for a clearer understanding.

Testing for Alignment Accuracy

Techniques to verify alignment postadjustment. Discussing acceptable tolerances and measurements.After making adjustments, you need to check if everything is straight and true. One good technique is the dial indicator method. This tool helps measure any tiny changes. You can also use a ruler to check distances. Acceptable tolerances are usually small, like a few thousandths of an inch. Never aim for too much; keep it simple!

- Use a dial indicator for precision.

- Check alignment against a ruler.

- Keep tolerances under 0.002 inches.

How do you know if the tailstock is aligned?

To check the tailstock alignment, look for any gaps. **A perfect alignment will have no space** between the tailstock and the lathe bed. You can spin a test piece to see if it wobbles. Any wobble means it’s not aligned!

Maintenance Tips for Tailstock Alignment

Preventative maintenance practices to avoid misalignment. Best practices for cleaning and lubricating the tailstock.Keeping the tailstock aligned is as important as keeping track of your lunch money—lose it, and things can get messy! Start with regular preventative maintenance. Check for any dirt or debris that may throw things off. Regularly clean your tailstock with a soft brush or cloth. A little lubricant can go a long way, too—think of it as a spa day for your tailstock! Use a few drops of oil to keep things running smoothly.

| Maintenance Tips | Frequency |

|---|---|

| Check for debris | Weekly |

| Clean surfaces | Monthly |

| Lubricate | Every 3 months |

FAQs on Tailstock Alignment

Common questions and expert answers regarding alignment. Troubleshooting tips for persistent alignment issues.Many users wonder about tailstock alignment and how to achieve it. Here are some common questions and answers that can help! For instance, one often-asked question is, “How do I check if my tailstock is aligned?” The simple answer is: Use a test bar to see if it lines up with the spindle. If it doesn’t, no worries! Just adjust the tailstock until it does. Another concern is, “What if I still have alignment problems?” If alignment persists, consider checking the bed and ways for any damage. Remember, even the best lathes can throw a tantrum now and then!

| Question | Answer |

|---|---|

| How can I tell if my tailstock is aligned? | Check with a test bar to ensure it matches the spindle. |

| What should I do if alignment issues continue? | Inspect the bed and ways for damage. |

Case Studies: Successful Tailstock Alignments

Realworld examples of alignment challenges and resolutions. Lessons learned from professional machinists and workshops.Many machinists faced tricky tailstock alignment issues. One workshop struggled with uneven cuts, making parts look like they were related to a potato. After some head-scratching, they discovered adjusting the tailstock fixed the problem. Another case involved a novice who learned to double-check alignments after a failed project. “Measure twice, cut once!” became their new motto. These experiences teach us that attention to detail matters and that alignment can truly save the day!

| Challenge | Resolution | Lesson Learned |

|---|---|---|

| Uneven cuts | Adjusted tailstock | Attention to detail |

| Failed project | Double-checked alignment | Measure twice |

Conclusion

In summary, aligning a gearhead metal lathe tailstock is crucial for accurate work. You want to ensure it’s straight to avoid mistakes. Regular checks keep your lathe running well. Don’t hesitate to adjust or ask for help if you need it. For more tips, consider reading guides or watching videos to improve your skills further!FAQs

What Are The Common Signs That Indicate Misalignment In The Tailstock Of A Metal Lathe?If the tailstock is misaligned, you might see some funny things happen when you work. The tool can cut unevenly, making bumps on your metal. You might also notice that your pieces do not fit together well. Sometimes, the tailstock can even cause the piece to wobble. These signs say it’s time to check the alignment!

How Can I Check The Tailstock Alignment On My Metal Lathe To Ensure It’S Properly Set For Accurate Machining?To check the tailstock on your metal lathe, first, use a small drill bit or a tool. Place it in the tailstock’s holder and lock it in place. Then, move the tailstock close to the chuck. Look to see if the drill bit lines up straight with the center of the chuck. If it’s off, you may need to adjust the tailstock until it matches up perfectly.

What Tools Are Typically Used For Aligning The Tailstock On A Metal Lathe?To align the tailstock on a metal lathe, we usually use a few simple tools. A dial indicator helps us check the tailstock’s position. A leveling tool is also helpful to ensure everything is straight. You might need a wrench to adjust any screws. These tools help us make sure the tailstock is in the right place for cutting metal safely.

What Are The Steps To Adjust The Tailstock If It Is Found To Be Out Of Alignment?To adjust the tailstock, first, check if it’s straight. Look down the length of the machine to see if it lines up. If it’s not straight, loosen the screws on the tailstock. Next, gently move it until it lines up correctly. Finally, tighten the screws back up and check again.

How Does Tailstock Alignment Affect The Overall Precision And Quality Of Work Produced On A Metal Lathe?Tailstock alignment helps keep the metal piece steady while it spins. If it’s not aligned, the piece may wobble or create uneven cuts. This can lead to mistakes and lower quality work. By keeping the tailstock aligned, you make better, more precise parts. This means your projects will look nicer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate Misalignment In The Tailstock Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock is misaligned, you might see some funny things happen when you work. The tool can cut unevenly, making bumps on your metal. You might also notice that your pieces do not fit together well. Sometimes, the tailstock can even cause the piece to wobble. These signs say it’s time to check the alignment!”}},{“@type”: “Question”,”name”: “How Can I Check The Tailstock Alignment On My Metal Lathe To Ensure It’S Properly Set For Accurate Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the tailstock on your metal lathe, first, use a small drill bit or a tool. Place it in the tailstock’s holder and lock it in place. Then, move the tailstock close to the chuck. Look to see if the drill bit lines up straight with the center of the chuck. If it’s off, you may need to adjust the tailstock until it matches up perfectly.”}},{“@type”: “Question”,”name”: “What Tools Are Typically Used For Aligning The Tailstock On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, we usually use a few simple tools. A dial indicator helps us check the tailstock’s position. A leveling tool is also helpful to ensure everything is straight. You might need a wrench to adjust any screws. These tools help us make sure the tailstock is in the right place for cutting metal safely.”}},{“@type”: “Question”,”name”: “What Are The Steps To Adjust The Tailstock If It Is Found To Be Out Of Alignment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock, first, check if it’s straight. Look down the length of the machine to see if it lines up. If it’s not straight, loosen the screws on the tailstock. Next, gently move it until it lines up correctly. Finally, tighten the screws back up and check again.”}},{“@type”: “Question”,”name”: “How Does Tailstock Alignment Affect The Overall Precision And Quality Of Work Produced On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tailstock alignment helps keep the metal piece steady while it spins. If it’s not aligned, the piece may wobble or create uneven cuts. This can lead to mistakes and lower quality work. By keeping the tailstock aligned, you make better, more precise parts. This means your projects will look nicer and work better!”}}]}