Gearhead Metal Lathe Threading Dial: A Complete Guide

Gearhead Metal Lathe Threading Dial

A gearhead metal lathe threading dial helps you create accurate threads every time. This handy tool lets you easily adjust the depth and distance of your cuts. Have you ever struggled with getting the right measurement? This is where the threading dial shines. It offers a straightforward way to make those tricky adjustments possible. By understanding how to use it effectively, you can turn out precise threads on your projects, making your work smoother and more professional.Understanding Gearhead Metal Lathes

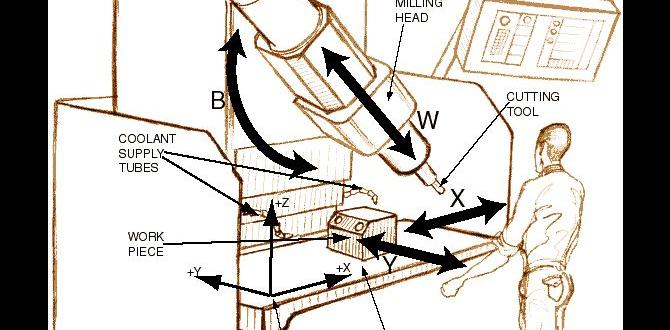

Definition and features of gearhead metal lathes. Advantages of using gearhead metal lathes for threading applications.A gearhead metal lathe is a tool for shaping metal. It features a rotating workpiece and a cutting tool. This machine has a simple gear system for easy speed changes. Gearhead lathes are known for their strong power and precision. They work great for threading, which is making screws and bolts. Users enjoy smoother operations with better control. This leads to quality results and less waste.

- Powerful and reliable

- Easy speed adjustments

- High accuracy in threading

Why choose gearhead metal lathes for threading?

Gearhead lathes make threading easier and faster. They have high torque, which helps when cutting tough materials. Many professionals prefer them for consistent results.

Components of the Threading Dial

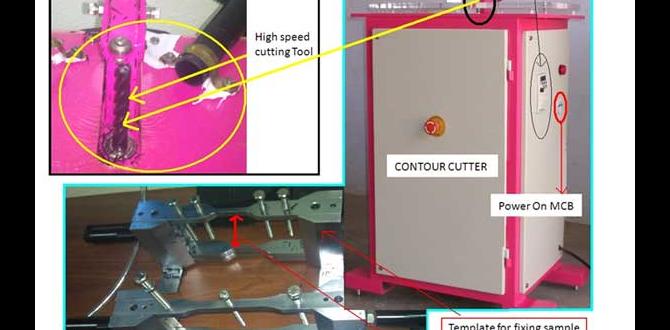

Detailed description of the threading dial and its function. Importance of precision in the threading dial for accurate cuts.A threading dial is a small but mighty tool on a gearhead metal lathe. It helps create precise threads on metal pieces. This dial works by showing where to start cutting the threads. Without a good threading dial, the cuts could be uneven. Precision in its design means that the lathe can make accurate cuts every time. Every detail counts, as it can make a big difference in the final product.

Why is precision important in a threading dial?

Precision is important because it ensures clean, accurate threads. This makes it easier to fit parts together. If threads are off, the pieces may not connect well, leading to problems. A well-calibrated threading dial keeps everything in check.

Key reasons for precision:

- Ensures that parts fit correctly.

- Reduces the chance of mistakes.

- Improves overall product quality.

Setting Up Your Gearhead Metal Lathe for Threading

Stepbystep guide to preparing the lathe for threading operations. Tips for aligning the threading dial correctly.To get your gearhead metal lathe ready for threading, follow these simple steps. First, check that everything is clean. A tidy lathe is a happy lathe! Next, align the threading dial. It needs to match the lead screw. Don’t worry; it won’t bite. Set the gears on the correct ratio for your project. Finally, test everything with a scrap piece. Remember, practice makes perfect and makes you look like a genius!

| Step | Action |

|---|---|

| 1 | Clean the lathe |

| 2 | Align the threading dial |

| 3 | Set the gear ratio |

| 4 | Test with scrap |

Following this guide helps you avoid any threading disasters that might make you cry into your coffee!

Threading Techniques Using the Dial

Explanation of singlepoint threading and other methods. Best practices for operating the threading dial efficiently.Using the threading dial can turn a metal lathe into a thread-making wizard. First, let’s explore single-point threading. This method uses one cutting tool to shape the material into threads. It’s like using a pencil to draw lines, but way cooler! Now, there are other techniques too, like chasing threads where you follow existing grooves.

Best practices for the threading dial? Always keep your eye on the dial. It’s your buddy! Move slowly and steady; rushing can result in a big mess. A smooth touch yields better results. Remember, “haste makes waste,” especially in threading. Here’s a quick summary:

| Technique | Description |

|---|---|

| Single-Point Threading | One tool shapes the threads. |

| Chasing Threads | Follows existing lines. |

With these tips, you’ll be threading like a pro in no time!

Troubleshooting Common Issues

Identification of common problems when using the threading dial. Solutions and tips for maintaining optimal performance.Many users experience troubles with the threading dial. Common problems include inaccurate measurements and dial slips. To solve these issues, check the dial’s alignment and ensure it is clean. Proper lubrication can improve its performance significantly. Regular maintenance keeps it running smoothly.

- Clean the threading dial regularly.

- Lubricate moving parts to avoid sticking.

- Check the alignment for precise threading.

What should I do if the threading dial slips?

If the threading dial slips, adjust its tightness or clean the parts around it for better grip.

Safety Precautions When Threading

Essential safety measures to follow while using metal lathes. Personal protective equipment (PPE) recommendations.Using a metal lathe can be fun and rewarding, but safety is important. Always wear the right gear to protect yourself. Here are some essential safety measures:

- Always wear safety goggles to protect your eyes.

- Use gloves to keep your hands safe from sharp edges.

- Wear a dust mask when cutting metal to prevent breathing in debris.

- Keep long hair tied back and avoid loose clothing.

- Use ear protection if the machine is loud.

Following these safety precautions helps ensure a safe and productive experience. Remember, safety first!

What personal protective equipment should you use with a metal lathe?

Always use safety goggles, gloves, a dust mask, and ear protection to stay safe while working with a metal lathe. These items will protect against injuries and help you focus on your work.

Advanced Tips for Experienced Users

Techniques for achieving more complex threading patterns. Custom modifications and enhancements for improved performance.For those who have experience with lathes, there are ways to create complex threading patterns. One method is to adjust the threading dial for precise cuts. Experimenting with the speed can also give different results. Custom modifications can help, such as:

- Adding a backlash eliminator for better accuracy.

- Using advanced gears to change the threading pitch.

- Upgrading the motor for smoother operation.

- Creating a custom tool holder for special tools.

These improvements can enhance performance and lead to impressive results in your projects!

What are the best ways to improve threading on a metal lathe?

Adjusting speed, using finer tools, and customizing the lathe can greatly improve threading quality. Make sure each part works well together for the best outcome.

Resources for Further Learning

Recommended books and documentation on metal lathe threading. Online courses and tutorials for skill enhancement.Learning more about metal lathe threading can be fun and exciting! Start with some great books that dive into this topic. Look for guides that explain threading techniques clearly. You can also find online courses that will turn you into a threading wizard. Videos can show you how to use the gearhead metal lathe threading dial effectively. It’ll be like magic when you see those threads forming!

| Resource Type | Recommended Resources |

|---|---|

| Books | Metalworking: A Beginner’s Guide |

| Books | The Complete Guide to Metal Lathes |

| Online Courses | Introduction to Metal Lathe Basics |

| Online Tutorials | YouTube – Metal Lathe Projects |

Conclusion

In summary, the gearhead metal lathe threading dial is essential for precise cutting. It helps you measure and adjust threads accurately. We can use it to create strong, fitted parts. To improve your skills, practice regularly and explore tutorials online. Embrace the challenge, and you’ll become a pro at using your lathe in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Gearhead Metal Lathe Threading Dials:Sure! Here are five related questions on gearhead metal lathe threading dials: 1. What is a threading dial? A threading dial helps you set the right distance for cutting threads on a metal lathe. 2. How do you use a threading dial? You turn the handle on the lathe and watch the numbers on the dial. 3. Why is a threading dial important? It helps make sure the threads are even and fit together well. 4. Can you use a lathe without a threading dial? Yes, but it makes threading much harder and less accurate. 5. What happens if you don’t use the threading dial correctly? You might make uneven threads, which can cause parts to not fit right.

Sure! Just give me the question you want me to answer, and I’ll be happy to help!

What Is The Purpose Of The Threading Dial On A Gearhead Metal Lathe?The threading dial helps you cut threads on metal pieces. It shows you when to start and stop moving the tool. With this dial, you can make the threads even and nice. It makes your work easier and more accurate.

How Do You Properly Set The Threading Dial For Accurate Thread Cutting?To set the threading dial for accurate thread cutting, first, start your machine and get it ready. Turn the threading dial so its number matches the thread pitch or size you want. Next, look closely when the tool comes around and wait until the dial lines up with a mark. Press the pedal to start cutting once they match. This helps you make a perfect thread!

What Factors Should You Consider When Using The Threading Dial For Different Thread Pitches?When using the threading dial, you should think about the thread pitch. Thread pitch is how close the threads are together. You need to check the type of thread you are using. Make sure the threading dial matches that pitch. Finally, keep your machine running smoothly for the best results.

Can You Explain The Difference Between A Threading Dial And Other Types Of Dials Or Indicators Used On Lathes?A threading dial helps you make threads on metal pieces. It shows you when to move the tool to cut the threads evenly. Other dials, like the speed dial, show how fast the lathe is working. Unlike these dials, the threading dial is special for making screw-like patterns. You use them together, but each has a different job.

What Troubleshooting Steps Can You Take If The Threading Dial Is Not Aligning Correctly During The Threading Process?If the threading dial isn’t aligning, first check if the machine is set up correctly. You can make sure the needle is in the right position. Next, look at the thread path to see if it’s correct. If the dial still doesn’t align, try turning it to see if it moves smoothly. Lastly, you can ask a grown-up for help if you’re still stuck.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Gearhead Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on gearhead metal lathe threading dials: 1. What is a threading dial? A threading dial helps you set the right distance for cutting threads on a metal lathe. 2. How do you use a threading dial? You turn the handle on the lathe and watch the numbers on the dial. 3. Why is a threading dial important? It helps make sure the threads are even and fit together well. 4. Can you use a lathe without a threading dial? Yes, but it makes threading much harder and less accurate. 5. What happens if you don’t use the threading dial correctly? You might make uneven threads, which can cause parts to not fit right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you want me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Threading Dial On A Gearhead Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut threads on metal pieces. It shows you when to start and stop moving the tool. With this dial, you can make the threads even and nice. It makes your work easier and more accurate.”}},{“@type”: “Question”,”name”: “How Do You Properly Set The Threading Dial For Accurate Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the threading dial for accurate thread cutting, first, start your machine and get it ready. Turn the threading dial so its number matches the thread pitch or size you want. Next, look closely when the tool comes around and wait until the dial lines up with a mark. Press the pedal to start cutting once they match. This helps you make a perfect thread!”}},{“@type”: “Question”,”name”: “What Factors Should You Consider When Using The Threading Dial For Different Thread Pitches?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the threading dial, you should think about the thread pitch. Thread pitch is how close the threads are together. You need to check the type of thread you are using. Make sure the threading dial matches that pitch. Finally, keep your machine running smoothly for the best results.”}},{“@type”: “Question”,”name”: “Can You Explain The Difference Between A Threading Dial And Other Types Of Dials Or Indicators Used On Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you make threads on metal pieces. It shows you when to move the tool to cut the threads evenly. Other dials, like the speed dial, show how fast the lathe is working. Unlike these dials, the threading dial is special for making screw-like patterns. You use them together, but each has a different job.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can You Take If The Threading Dial Is Not Aligning Correctly During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the threading dial isn’t aligning, first check if the machine is set up correctly. You can make sure the needle is in the right position. Next, look at the thread path to see if it’s correct. If the dial still doesn’t align, try turning it to see if it moves smoothly. Lastly, you can ask a grown-up for help if you’re still stuck.”}}]}