Have you ever watched a metal lathe spin and wondered how it works? Picture a piece of metal whirling while sharp tools carve it into something amazing. That’s where gearhead metal lathes come into play. They are powerful machines that help create everything from early toys to big car parts.

Many people don’t realize just how important torque is in this process. Torque is the force that makes things turn. The right amount of torque helps a lathe cut through metal smoothly and quickly. Too little torque can ruin your project. But too much might damage the machine!

Isn’t it fascinating how gearhead metal lathes balance power and precision? These machines can be your best friend in a workshop. They bring ideas to life, allowing hobbyists and builders to explore their creativity. Imagine creating something entirely new with just a block of metal and a bit of torque!

Join us as we dive deeper into the world of gearhead metal lathes. We’ll explore how torque affects their operation and why it matters to anyone working with metal. Ready to unlock the secrets of this amazing tool?

Gearhead Metal Lathe Torque

When working with a gearhead metal lathe, understanding torque is crucial. Torque is the force that helps the lathe turn materials effectively. A higher torque means the lathe can cut tougher materials with ease. Imagine trying to twist a stubborn lid off a jar. More force makes it easier! This tool’s design allows for smoother operation and better outcomes in projects, making it a favorite among hobbyists and professionals alike.

Understanding Gearhead Metal Lathes

Definition and types of gearhead metal lathes. Key components and their functions.

Gearhead metal lathes are the superheroes of machining, transforming raw metal into beautiful shapes. These marvelous machines come in types like standard, CNC, and turret lathes. Each type has its style and purpose, kind of like superheroes with different powers! The main parts include the spindle, which holds the workpiece, and the tailstock, which supports it like a good friend. Don’t forget the carriage, guiding the cutting tool with precision. They’re all key players in making your metal magic happen!

| Parts | Function |

|---|---|

| Spindle | Holds the workpiece steady. |

| Tailstock | Supports the workpiece for better balance. |

| Carriage | Guides the cutting tool for accuracy. |

Importance of Torque in Metal Lathes

Explanation of torque and its relevance in metalworking. How torque affects machining performance.

Torque is a measure of how much force can make something turn. In metal lathes, torque is very important. It helps shape metal pieces smoothly. When there is enough torque, the machine can cut through tough materials easily. This means better work quality and faster results.

- Stronger torque leads to better cutting.

- More torque means fewer mistakes.

- Good torque helps keep the machine running longer.

Why is torque important in metalworking?

Torque is crucial because it determines the machine’s ability to cut and shape metal accurately. Without enough torque, the lathe may struggle to perform its job well, leading to rough finishes or damaged tools. Think of torque as the strength needed to turn tight screws. The more torque, the easier the job gets!

Factors Influencing Torque in Gearhead Metal Lathes

Motor power ratings and their impact on torque. Gear ratios and their effect on torque output.

Several factors play a big role in how torque works in gearhead metal lathes. First, the motor power rating is crucial. A stronger motor can produce more torque, like a superhero lifting heavy weights. Then there’s the gear ratio. Higher gear ratios can boost torque output, kind of like getting a power-up in a video game. It transforms your machine into a torque monster!

| Factor | Impact on Torque |

|---|---|

| Motor Power Rating | Higher ratings mean more torque |

| Gear Ratios | Boosts torque output significantly |

Understanding these factors will help you choose the best lathe for your projects without breaking a sweat (or your bank)! So, remember, more power and clever gearing equals more torque fun!

Calculating Torque for Optimal Performance

Formula for calculating torque in metal lathes. Practical examples and use cases.

To calculate torque in metal lathes, the formula is simple: Torque (T) = Force (F) × Distance (d). Picture it like using a wrench. The farther you grip, the easier it is to turn. Want a fun fact? A lathe can create about 100 foot-pounds of torque! Imagine trying to move a car with that much power!

| Force (F) | Distance (d) | Torque (T) |

|---|---|---|

| 10 lbs | 5 ft | 50 ft-lbs |

| 20 lbs | 3 ft | 60 ft-lbs |

| 15 lbs | 2 ft | 30 ft-lbs |

In practice, you can tweak your lathe settings based on your projects. For instance, if you’re turning metal for a toy car, a lower torque works fine. But for hefty parts like bike frames, crank up that torque! Remember, the right torque makes all the difference between smooth turning and a trip to the repair shop!

Comparing Gearhead vs. Belt Drive Lathes

Advantages and disadvantages of gearhead lathes. Torque performance comparison with belt drive lathes.

Gearhead lathes come with their own set of benefits and drawbacks. One clear advantage is their high torque performance, which means they can handle tough materials without breaking a sweat. This makes them great for big jobs! However, they can be heavier and more expensive compared to belt drive lathes. On the flip side, belt drive lathes are usually lighter and easier on the wallet, but can struggle with tougher tasks. Think of it this way: gears are like a strong bull, while belts are quick like a rabbit!

| Feature | Gearhead Lathes | Belt Drive Lathes |

|---|---|---|

| Torque Performance | High | Moderate |

| Weight | Heavy | Light |

| Cost | Higher | Lower |

Tuning Torque Settings for Different Materials

Recommended torque settings for various metals. Importance of adjusting torque for material properties.

Different metals require different torque settings for the best results. Adjusting torque is important because each metal has unique properties. Using the right torque helps you avoid damage and make accurate cuts. Here are some recommended settings:

- Aluminum: 20-30 ft-lbs

- Steel: 40-50 ft-lbs

- Brass: 15-25 ft-lbs

- Stainless Steel: 60-75 ft-lbs

Choosing the right torque leads to better results and a smoother process. Remember, adjusting for material properties is key to achieving the best outcomes!

What happens if torque settings are wrong?

Incorrect torque can cause broken tools, damaged materials, or poor finishes.

Common Problems Affecting Torque in Gearhead Lathes

Identification of torquerelated issues in operation. Solutions and recommended maintenance practices.

Operating a gearhead lathe can be tricky, especially when torque goes haywire. You might notice issues like slipping or sudden changes in speed. These problems often signal a need for maintenance. Regular checks on belts, bearings, and lubrication can work wonders. Think of it as giving your lathe a spa day! A well-maintained lathe purrs like a kitten and doesn’t misbehave. Remember, when torque dips, it’s like your lunch money disappearing—totally not cool!

| Problem | Solution |

|---|---|

| Slipping belts | Check and adjust tension |

| Worn bearings | Replace old bearings |

| Poor lubrication | Use the right oil regularly |

Choosing the Right Gearhead Metal Lathe for Your Needs

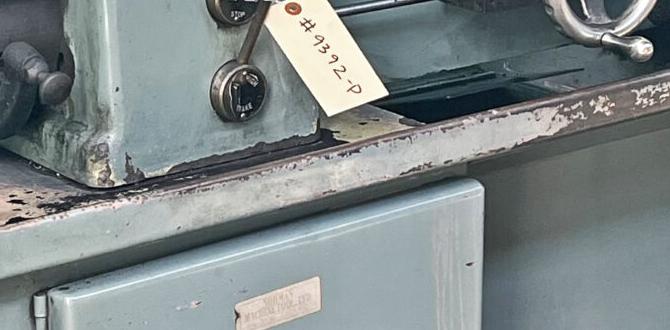

Key specifications to look for related to torque. Popular brands and models with optimal torque capabilities.

Finding the right gearhead metal lathe can be exciting! Look for torque specs to match your projects. High torque means more power and smoother operations. Popular brands like Jet, Grizzly, and Haas offer great options. Their models often provide impressive torque ratings. Check these key features:

- Torque rating: Higher values mean better performance.

- Variable speed: Helps with different materials.

- Build quality: Stronger machines last longer.

What is a key specification for torque in a gearhead lathe?

Torque rating is crucial. It tells you how much force the lathe can handle, making all the difference in your work quality.

Conclusion

In conclusion, gearhead metal lathes offer high torque for efficient metalworking. They help you create precise parts easily. Understanding torque is key to getting the best performance. We recommend exploring different models and reading user reviews for informed choices. So, get started with your metal projects and enjoy the journey of creation!

FAQs

What Factors Determine The Optimal Torque Output Of A Gearhead Metal Lathe During Operation?

To find the best torque, we look at a few important things. First, the type of metal you are working with matters; harder metals need more power. Next, the speed of the lathe affects how much work it can do. The size of the gears also plays a role; bigger gears can give more strength. Lastly, keeping everything well-oiled and clean helps the machine run smoothly.

How Does The Torque Rating Of A Gearhead Metal Lathe Affect Its Ability To Cut Various Materials?

The torque rating of a gearhead metal lathe tells us how much power it has. If you have a high torque rating, you can cut harder materials, like steel, easily. Lower torque means it might struggle with tough materials and not cut well. It’s important to match the lathe’s torque to what you want to cut. That way, you get the best results!

What Is The Significance Of Torque In Relation To The Spindle Speed And Feed Rate On A Gearhead Metal Lathe?

Torque is the twisting force that helps the lathe cut metal. When the spindle speed is high, you need enough torque to keep cutting smoothly. If the feed rate, or how fast the tool moves, is too fast, the lathe may stall. So, good torque helps you make clean cuts, no matter how fast you’re going. It’s like having strong arms to help you lift heavy things easily!

How Can An Operator Safely Manage Torque Limitations When Machining Heavy-Duty Workpieces On A Gearhead Metal Lathe?

To safely manage torque limits on a gearhead metal lathe, you should start with lighter cuts. This way, the machine doesn’t work too hard. You can also check the machine’s manual for torque settings. Always pay attention to strange noises or vibrations, as they can mean trouble. If you’re unsure, it’s best to ask a more experienced person for help.

What Are The Common Signs Of Torque-Related Issues In Gearhead Metal Lathes, And How Can They Be Addressed?

Common signs of torque issues in gearhead metal lathes include strange noises, slow movement, or changes in speed. You might notice uneven cuts or a wobbly piece when working. To fix these problems, check the gears and belts for damage. Lubricate moving parts and ensure everything is tight. If needed, ask an expert for help.